Detoxification and fermentation method for meal for feed

A feed and soybean meal technology, which is applied in the field of detoxification and fermentation of feed meal, can solve the problems of feed production inconvenience, and achieve the effects of short preparation time, easy absorption and utilization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

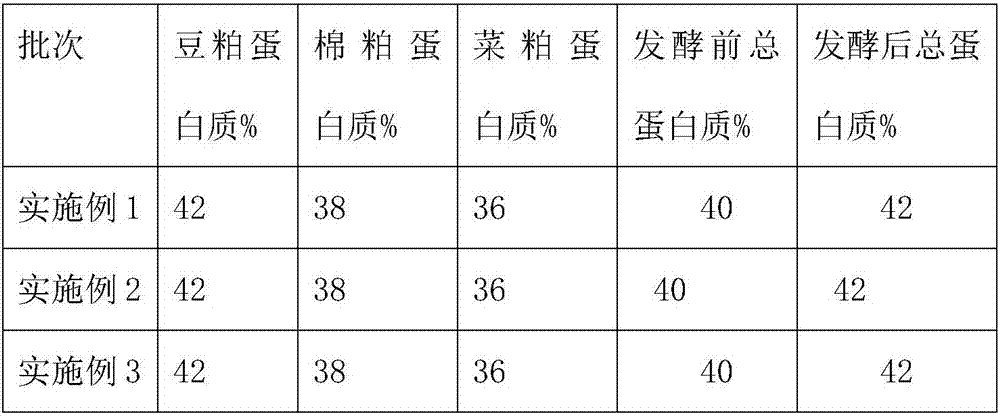

Embodiment 1

[0014] A method for detoxification and fermentation of feed meal, the specific steps are as follows:

[0015] Step 1, raw material screening: remove moldy and rotten raw materials, mix and pulverize them evenly according to the weight ratio of soybean meal: cotton meal: rapeseed meal is 3:1:1;

[0016] Step 2, fermentation: select 6 kg of mixed strains containing Bacillus subtilis, lactobacillus and saccharomyces, the strain content in the mixed strains is 18 billion / g, 10 kg of culture medium, pretreatment at a temperature of 36 degrees Celsius for 14 hour, obtain the activated bacteria enrichment liquid, add 415 kilograms of water, add the water enriched bacteria liquid to the 1000kg meal mixer prepared in advance, mix for 6 minutes, store the mixed meal in an airtight container, under natural conditions Sealed fermentation for 2.5 days, until the surface fermentation is completed when there is alcohol or earthy smell;

Embodiment 2

[0019] A method for detoxification and fermentation of feed meal, the specific steps are as follows:

[0020] Step 1, raw material screening: remove moldy and rotten raw materials, mix and pulverize them evenly according to the weight ratio of soybean meal: cotton meal: rapeseed meal is 5:1:1;

[0021] Step 2, fermentation: Select 9 kg of mixed strains containing Bacillus subtilis, Lactobacillus and saccharomyces, pretreat with 10 kg of culture medium, and pretreat at a temperature of 38 degrees Celsius for 14 hours to obtain an activated bacterial enrichment solution, add 415 kg of water, and add water Add the enrichment solution to the 1000kg meal mixer prepared in advance, mix for 7 minutes, store the mixed meal in a closed container, and ferment it under natural conditions for 2.5 days, until there is alcohol or earthy smell on the surface Fermentation complete;

[0022] Step 3, low-temperature drying: drying the fermented material in a low-temperature dryer at a temperat...

Embodiment 3

[0024] A method for detoxification and fermentation of feed meal, the specific steps are as follows:

[0025] Step 1, raw material screening: remove moldy and rotten raw materials, mix and pulverize them evenly according to the weight ratio of soybean meal: cotton meal: rapeseed meal is 3:1:1;

[0026] Step 2, fermentation: select 8 kg of mixed strains containing Bacillus subtilis, lactobacillus and saccharomyces, the strain content in the mixed strains is 16 billion / g, 10 kg of culture medium, pretreatment at a temperature of 37 degrees Celsius for 15 hour, to obtain the activated bacterial enrichment liquid, add 420 kg of water, add the water enriched bacterial liquid to the pre-made 1000kg meal mixer, mix for 8 minutes, and store the mixed meal in a closed container under natural conditions Sealed fermentation for 3 days, until the surface fermentation is completed when there is alcohol or earthy smell;

[0027] Step 3, low-temperature drying: drying the fermented material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com