Method for increasing fermentation stability and quality of mulberry wine

A stable, mulberry wine technology, applied in microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of unfavorable brewing of high-quality mulberry wine, the metabolic rate of yeast is not constant, and the quality of mulberry wine Instability and other problems, to achieve the effect of good market prospects, quality and stability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

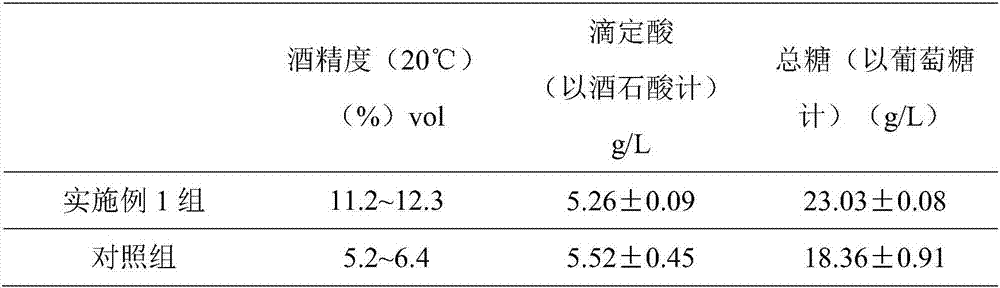

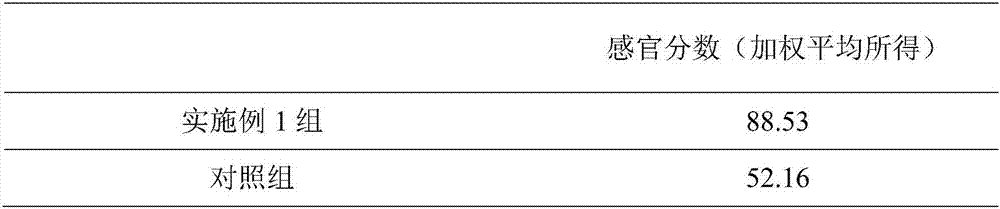

Examples

Embodiment 1

[0032] This embodiment provides a method for improving the fermentation stability and quality of mulberry wine, and the method is as follows:

[0033] a) Mulberry fruit thawing and selection: the frozen mulberry fruit is thawed at room temperature, and the mulberry with high maturity is selected.

[0034] b) Raw material crushing: The mulberry fruits with high maturity are selected and rinsed in 20-25°C water, and then crushed with a fruit and vegetable juicer. The crushed mulberry juice is placed at 18°C for temporary storage.

[0035] c) Preparation of tea polyphenol mixed liposomes: Dissolve 1.5 g of tea polyphenols and 0.5 g of sodium metabisulfite in 100 mL of 0.05 mol / L, pH 7.5 phosphate buffer to prepare tea polyphenol metabisulfite sodium phosphate Buffer. Take 30 mL of the above-mentioned tea polyphenol solution and place it in a beaker, heat it to 60°C, maintain a constant temperature, and stir vigorously. Dissolve 20 g of cholesterol in 1 L of absolute ethanol to obtai...

Embodiment 2

[0053] This embodiment provides a method for improving the fermentation stability and quality of mulberry wine, and the method is as follows:

[0054] a) Squeezing mulberry fruit juice: squeezing the fresh mulberry fruit after blanching treatment to obtain mulberry juice.

[0055] k) Preparation of tea polyphenol mixed liposomes: 1g tea polyphenols and 2g sodium metabisulfite are dissolved in 100mL 0.05mol / L, pH 7.5 phosphate buffer to prepare tea polyphenol metabisulfite sodium phosphate buffer . Take 30 mL of the above-mentioned tea polyphenol solution and place it in a beaker, heat it to 70°C, maintain a constant temperature, and stir vigorously. Dissolve 5 g of cholesterol in 1 L of absolute ethanol to obtain a cholesterol ethanol solution. Use a 10 mL syringe to quickly inject the cholesterol ethanol solution into the beaker containing the tea polyphenol pyrosulfite sodium phosphate buffer solution, stir for 30 minutes, and then rotate and evaporate at 65°C and a vacuum of 0...

Embodiment 3

[0064] This embodiment provides a method for improving the fermentation stability and quality of mulberry wine, and the method is as follows:

[0065] a) Squeezing mulberry fruit juice: squeezing the fresh mulberry fruit after blanching treatment to obtain mulberry juice.

[0066] b) Preparation of tea polyphenol mixed liposome: 2g tea polyphenol and 3g sodium metabisulfite are dissolved in 100mL 0.05mol / L, pH7.5 phosphate buffer to prepare tea polyphenol metabisulfite sodium phosphate buffer . Take 30 mL of the above-mentioned tea polyphenol solution and place it in a beaker, heat it to 70°C, maintain a constant temperature, and stir vigorously. Dissolve 50 g of cholesterol in 1 L of absolute ethanol to obtain a cholesterol ethanol solution. Use a 10mL syringe to quickly inject the cholesterol ethanol solution into the beaker containing the tea polyphenol pyrosulfite sodium phosphate buffer solution, stir for 30 minutes, and then rotate and evaporate at 45°C and a vacuum of 0.2M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com