Composite Additives for Electrolytic Copper Foil and Its Deposition Process

A composite additive and electrolytic copper foil technology, applied in electrolytic process, electroforming, etc., can solve the problems of reducing battery power and capacity, rough surface of copper foil, low tensile performance, etc., and achieve high tensile strength and elongation, The effect of fine and smooth grain structure and excellent charge and discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment discloses a composite additive for electrolytic copper foil, the composite additive consists of:

[0025] The total content of sodium polydithiodipropane sulfonate or sodium allyl sulfonate is 20ppm, quaternary ammonium salt 5ppm, gelatin 20ppm, sodium isethionate 10ppm, chlorine 15ppm, and the flow rate of the organic mixed additive is 400mL / min. According to the above-mentioned composite additives, the deposition process flow of deposited copper foil is as follows:

[0026] Take the electrolytic solution whose copper content is 70g / L, sulfuric acid content is 90g / L, chloride ion is 15ppm, and temperature is 45°C, and then add the composite additive to the electrolytic solution so that the electrolytic solution has a flow rate of 45m 3 / h, current density 5000A / m 2 Electrodeposition was carried out under the parameters.

Embodiment 2

[0027] Example 2: This example discloses a composite additive for electrolytic copper foil. The composite additive is composed of: sodium polydisulfide dipropane sulfonate or sodium allyl sulfonate with a total content of 40ppm, quaternary ammonium salt 10ppm, gelatin 50ppm, Sodium isethionate 10ppm, chlorine 20ppm, the organic mixed additive flow rate is 500mL / min.

[0028] According to the above-mentioned composite additives, the deposition process flow of deposited copper foil is as follows:

[0029] The copper content in the electrolyte is 80g / L, the sulfuric acid content is 140g / L, and the temperature is 50°C. Add organic mixed additives to the electrolyte so that the flow rate of the electrolyte is 70m 3 / h, current density 7000A / m 2 electrodeposition under conditions.

Embodiment 3

[0030] Example 3: This example discloses a composite additive for electrolytic copper foil. The composite additive is composed of: sodium polydisulfide dipropane sulfonate or sodium allyl sulfonate with a total content of 80 ppm, quaternary ammonium salt 15 ppm, gelatin 70 ppm, Sodium isethionate 30ppm, chlorine 30ppm, the organic mixed additive flow rate is 600mL / min.

[0031] According to the above-mentioned composite additives, the deposition process flow of deposited copper foil is as follows:

[0032] The copper content in the electrolyte is 90g / L, the sulfuric acid content is 130g / L, and the temperature is 60°C. Add organic mixed additives to the electrolyte so that the flow rate of the electrolyte is 80m 3 / h, current density 8500A / m 2 electrodeposition under conditions.

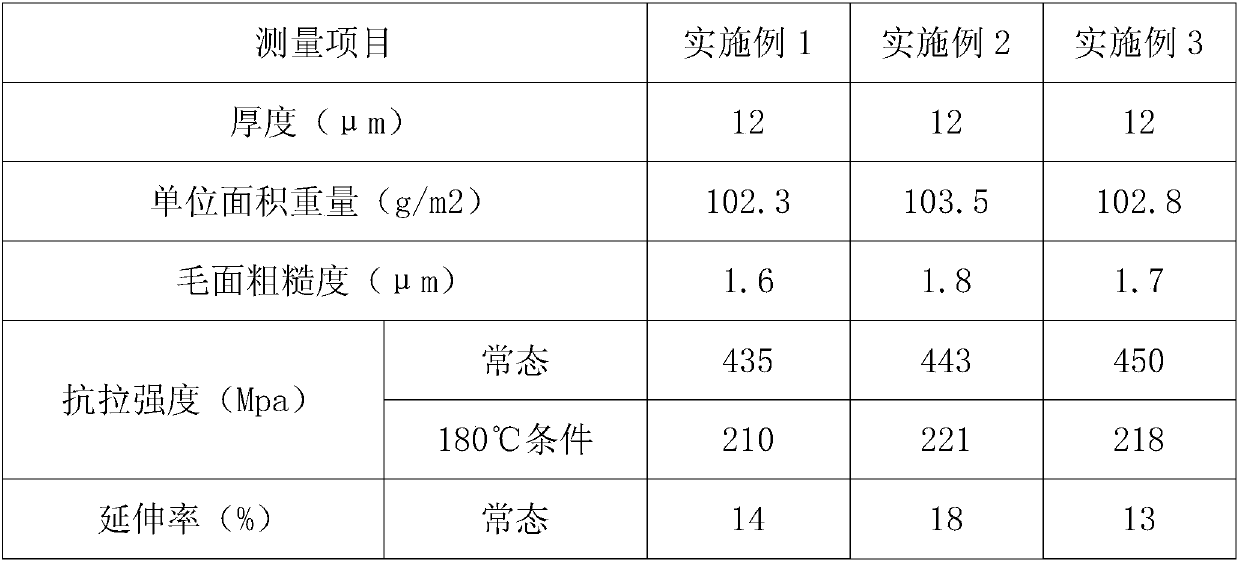

[0033] Please refer to Table 1, which is the physical performance table of the finished copper foils of Examples 1 to 3. It can be seen that the electrolytic copper foils for automotive power batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com