Shampoo composition

A composition and shampoo technology, applied in hair care, cosmetics, cosmetic preparations, etc., can solve the problems of cloudy and intransparent appearance, slow foaming, solubilization of amphiphilic substances, etc., and achieve long-term stability Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

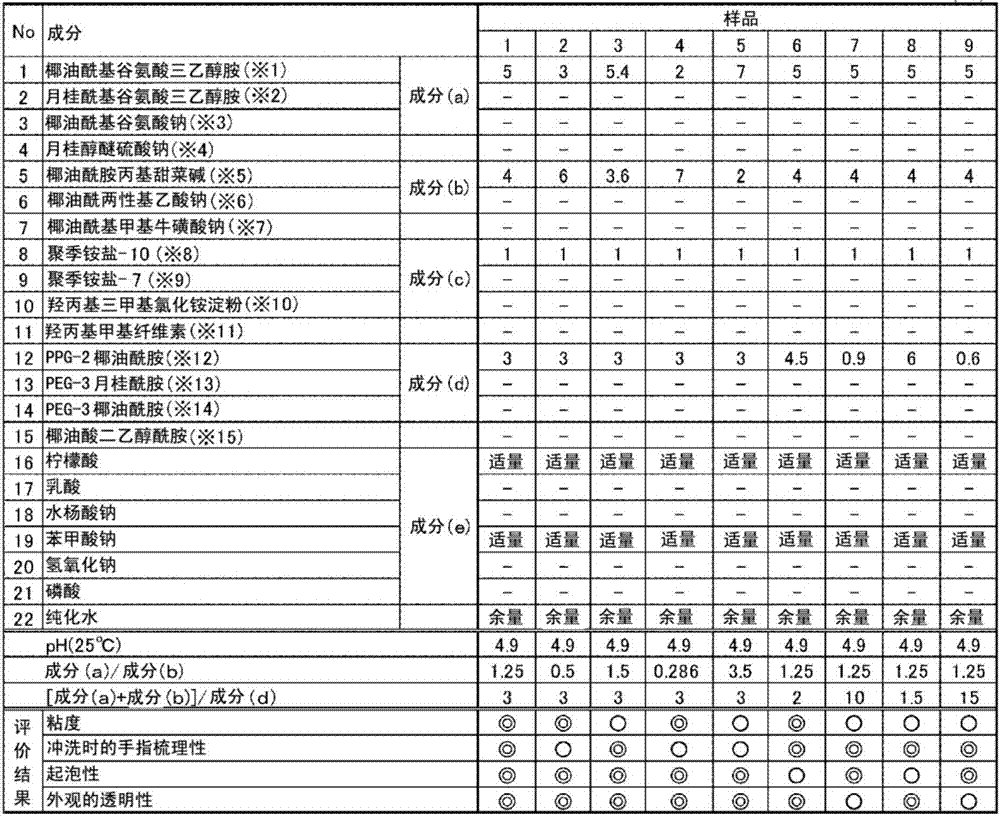

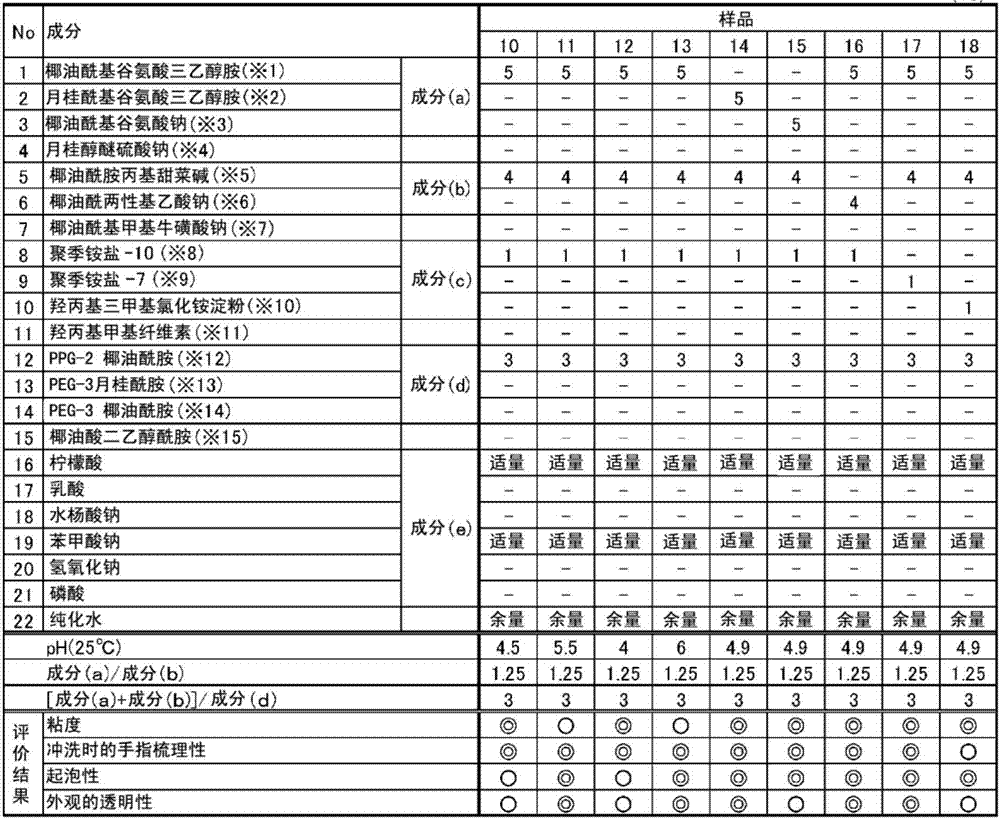

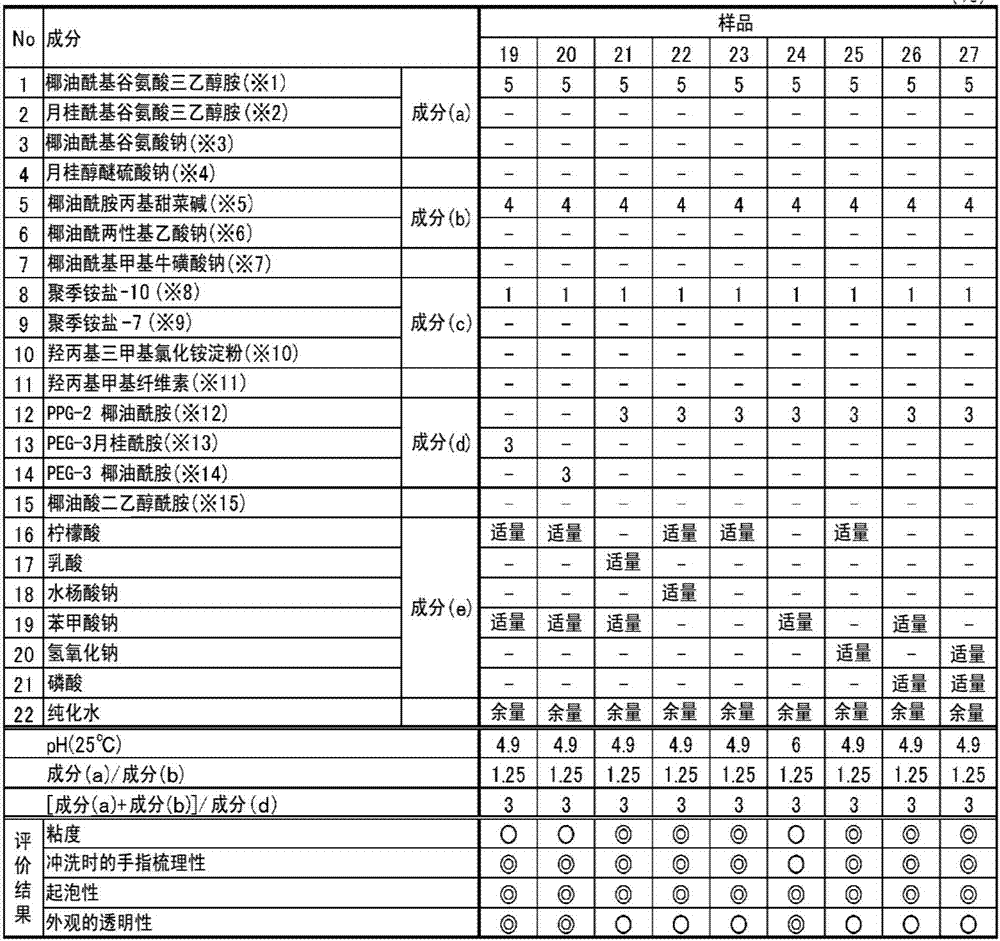

[0074] Samples 1-37: Shampoo compositions

[0075] Shampoo compositions shown in the following Tables 1 to 4 were prepared by the following production methods, with respect to (i) viscosity, (ii) foaming properties, (iii) finger combability during rinsing, and (iv) appearance Transparency was evaluated and judged in accordance with the evaluation methods and judgment criteria shown below, and the results are shown in Tables 1 to 4 together.

[0076] [Table 1]

[0077] (%)

[0078]

[0079] (*1) Cocoyl glutamic acid triethanolamine salt 30% aqueous solution AMISOFT CT-12 (manufactured by Ajinomoto Inc.)

[0080] (*2) Lauroyl glutamic acid triethanolamine salt 30% aqueous solution AMISOFT LT-12 (manufactured by Ajinomoto Inc.)

[0081] (*3) Cocoyl glutamic acid sodium salt 25% aqueous solution AMISOFT CS-22 (manufactured by Ajinomoto Inc.) (*4) 27% aqueous solution of sodium lauryl ether sulfate Alscope TH-330 (manufactured by Toho Chemical Co., Ltd.)

[0082] (*5) Cocami...

Embodiment 2

[0152] Example 2: Shampoo composition

[0153] (Element):(%)

[0154] 1 Triethanolamine lauroyl glutamate (30% aqueous solution) (※2): 20

[0155] 2 Sodium cocoamphoacetate (26.5% aqueous solution) (※7): 15

[0156] 3 Sodium olefin sulfonate (37% aqueous solution) (※5): 15

[0157] 4 Hydroxypropyltrimethylammonium Chloride Hyaluronic Acid (*17): 1

[0158] 5 PEG-3 lauramide (*14): 3

[0159] 6 ethyl oleate: 0.2

[0160] 7 Citric acid: 0.8

[0161] 8 Salicylic acid: 0.01

[0162] 9 Malic acid: 0.01

[0163] 10 Sodium benzoate: 0.5

[0164] 11 Purified water: balance

[0165] (*17) Hyaloveil P (manufactured by Kewpie Corporation)

[0166] (Production method)

[0167] A: A part of component 11 and components 1 to 3 were uniformly mixed at 80°C.

[0168] B: Ingredient 4 was dispersed in the remainder of Ingredient 11 at room temperature.

[0169] C: Add B to A, and mix uniformly at 80°C.

[0170] D: Add components 5 and 6 to C, and mix uniformly at 80°C.

[0171] E:...

Embodiment 3

[0176] Example 3: Body Shampoo

[0177] (Element):(%)

[0178] 1 Triethanolamine lauroyl glutamate (30% aqueous solution) (※2): 20

[0179] 2 Sodium cocoamphoacetate (26.5% aqueous solution) (※7): 15

[0180] 3 Sodium olefin sulfonate (37% aqueous solution) (※5): 15

[0181] 4 Polyquaternium-10 (※18): 0.02

[0182] 5 PPG-2 Cocamide (※13): 3

[0183] 6 Vitamin E: 0.05

[0184] 7 Citric acid: 0.8

[0185] 8 Glycosyl trehalose: 0.5

[0186] 9 bis(lauramide glutamine) sodium lysine solution (30% solution): 1

[0187] 10 Sodium benzoate: 0.5

[0188] 11 Purified water: balance

[0189] (*18) Catinal HC-100 (manufactured by Toho Chemical Industry Co., Ltd.)

[0190] (Production method)

[0191] A: A part of component 11 and components 1 to 3 were uniformly mixed at 80°C.

[0192] B: Ingredient 4 was dispersed in the remainder of Ingredient 11 at room temperature.

[0193] C: Add B to A, and mix uniformly at 80°C.

[0194]D: Add components 5 and 6 to C, and mix uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com