Nanofiber catalyst and preparation method thereof

A nanofiber and catalyst technology, applied in the field of nanofiber catalyst and its preparation, can solve the problems of limited effective catalyst load, low catalyst external diffusion rate, complex catalyst manufacturing process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

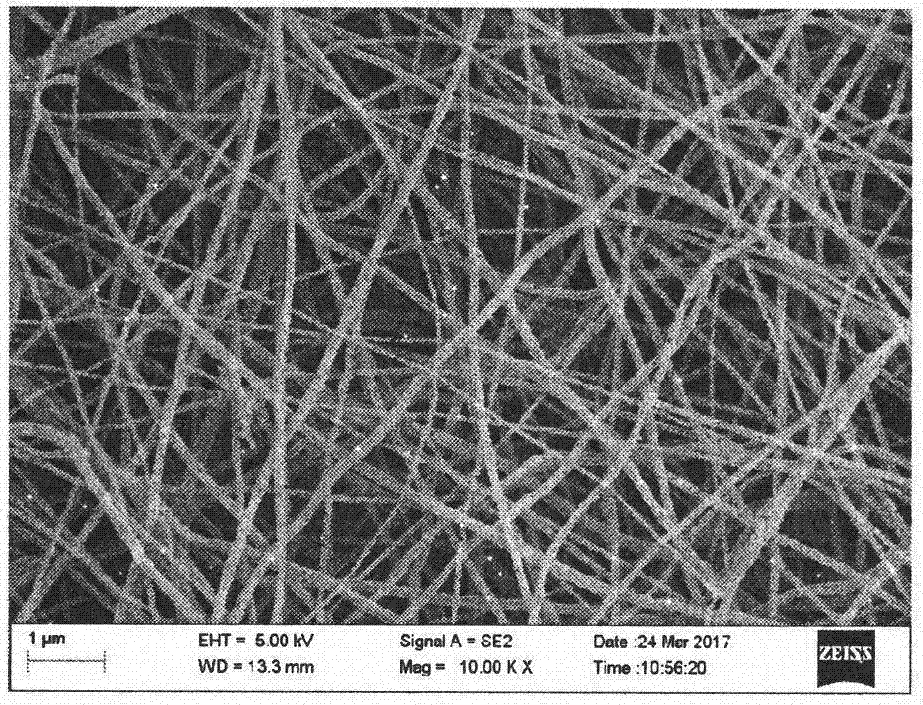

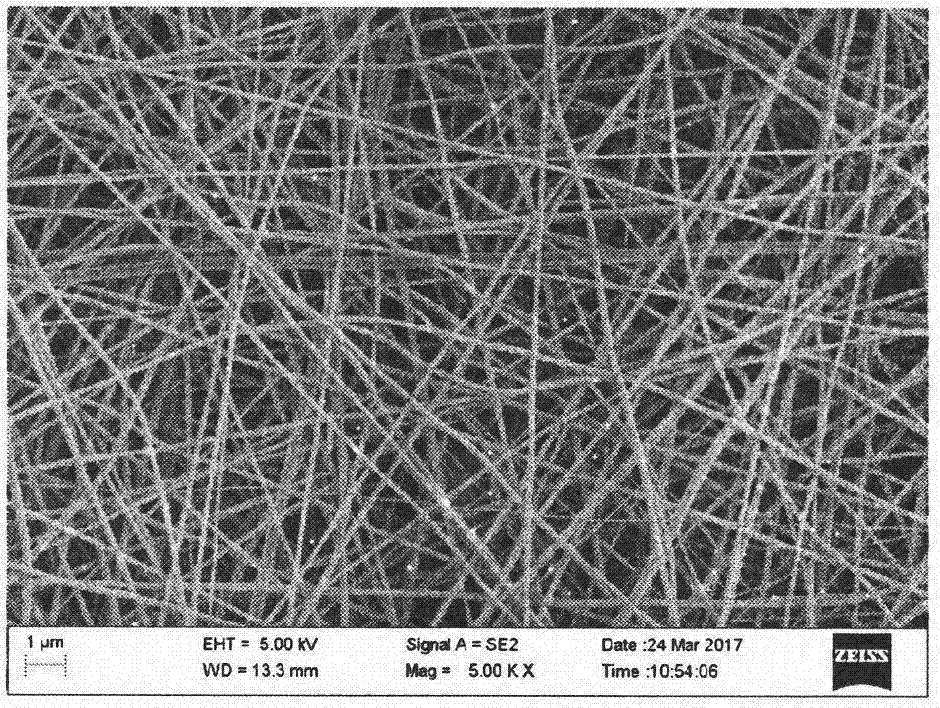

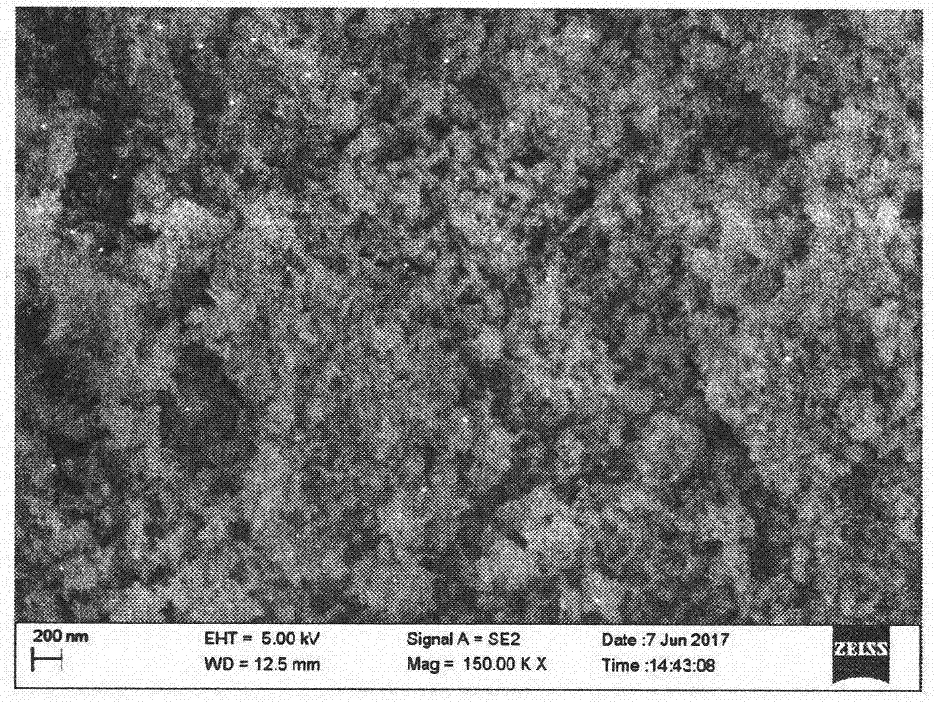

Image

Examples

Embodiment 1

[0039]Set Y(NO 3 ) 3 ·6H 2 O(1.8754mmol), Mn(CH 3 COO) 2 4H 2 O (3.75mmol), polyvinylpyrrolidone (PVP, K=90, 1g) was dissolved in ethanol (9mL) and deionized water (10mL), and stirred continuously at room temperature for 10h to obtain a mixed solution A;

[0040] Put the mixed solution A into the syringe pump, set the distance from the needle to the receiving plate to 15cm, adjust the voltage to 15KV, set the injection speed to 0.05mm / min, and adjust the air humidity to 15%. ) to spin the sol, then dry the spun nanofibers at a high temperature in an oven, and after cooling to room temperature, put the obtained nanofibers containing yttrium and manganese into a muffle furnace for high-temperature calcining; the heating rate setting As follows: from room temperature to 450°C at a heating rate of 25°C / h for 2 hours, then at the same heating rate to 600°C for 2 hours, to 800°C for 4 hours, and finally cool down to room temperature naturally. The nanofiber catalyst YMn can be...

Embodiment 2

[0043] will be used as Sm(NO 3 ) 3 ·6H 2 O(1.8754mmol), Mn(CH 3 COO) 2 4H 2 O (3.75mmol), polyvinylpyrrolidone (PVP, K=90, 1g) was dissolved in ethanol (9mL) and deionized water (10mL), and stirred continuously at room temperature for 10h to obtain a mixed solution B;

[0044] Put the mixed solution B into the syringe pump, set the distance from the needle to the receiving plate to 15cm, adjust the voltage to 15KV, set the injection speed to 0.05mm / min, and adjust the air humidity to 15%. ), the sol was spun out, and then the spun nanofibers were dried in an oven at a high temperature. After cooling to room temperature, the obtained nanofibers were calcined in a muffle furnace at a high temperature; the heating rate was set as follows: from room temperature to The heating rate of 25°C / h was raised to 450°C for 2 hours, then raised to 600°C for 2 hours at the same heating rate, and kept at 800°C for 4 hours, and finally cooled to room temperature naturally. Nanofiber cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com