Preparation method of natural ajoene

A technology of ajoene and garlic, which is applied in the field of preparation of natural garlic ajoene, can solve the problems of low ajoene purity, complicated extraction process, and difficulty in industrialized production, and achieve strong practical value, safe and easy solvent The effect of gaining and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

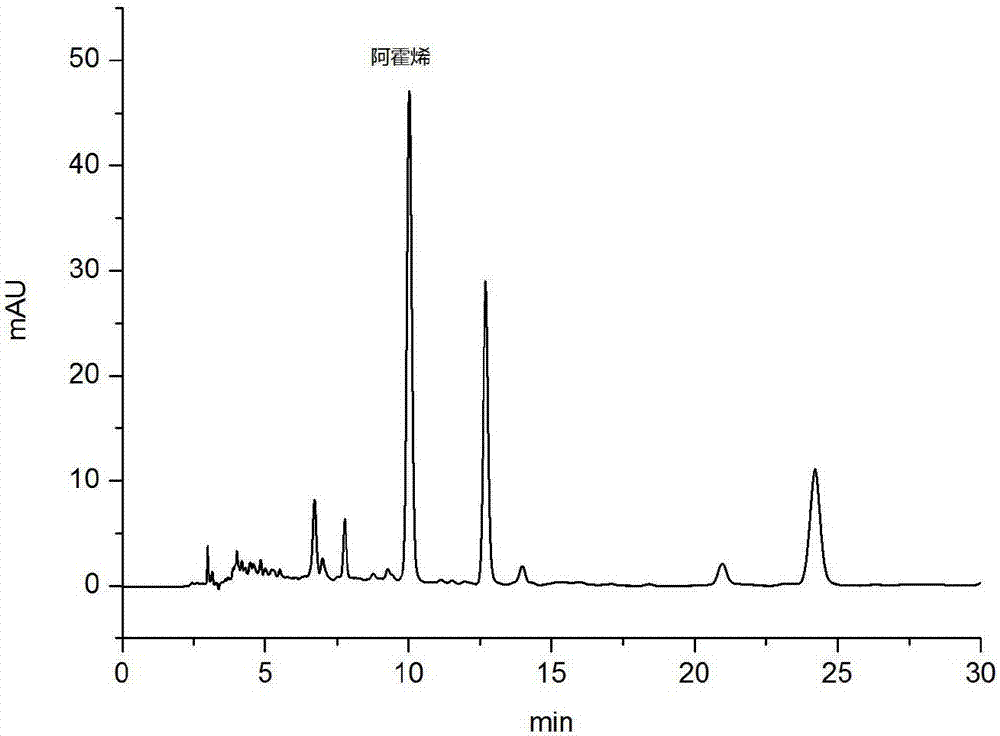

Examples

Embodiment 1

[0051] 1, get the garlic 10Kg that produces from Shandong, squeeze the juice with juice extractor after pulverizing, get garlic juice, the yield of garlic juice is 30%.

[0052] 2. Add 3Kg of 0.5% sodium bicarbonate solution to the above garlic juice, mix well, place in a temperature-controlled fermenter, adjust the temperature to 30°C, and ferment for 2 days.

[0053] 3. After the mixture is fermented for 2 days, take the oil in the upper layer of the mixture, add 500g of olive oil, mix well, and set aside.

[0054] 4. Extract the above-mentioned olive oil mixture with 65% ethanol, extract 3 times, each 500mL, combine 3 times of 65% ethanol extracts. The extract is concentrated under reduced pressure at a temperature of 55-75° C. to remove ethanol in the extract to obtain ajoene oil.

[0055] 5. Take carbon eighteen bonded silica gel C 18 1Kg, packed into a glass column for chromatography, and ajoene oil was loaded dry.

[0056] 6. Take 5Kg of 30% ethanol to elute the chro...

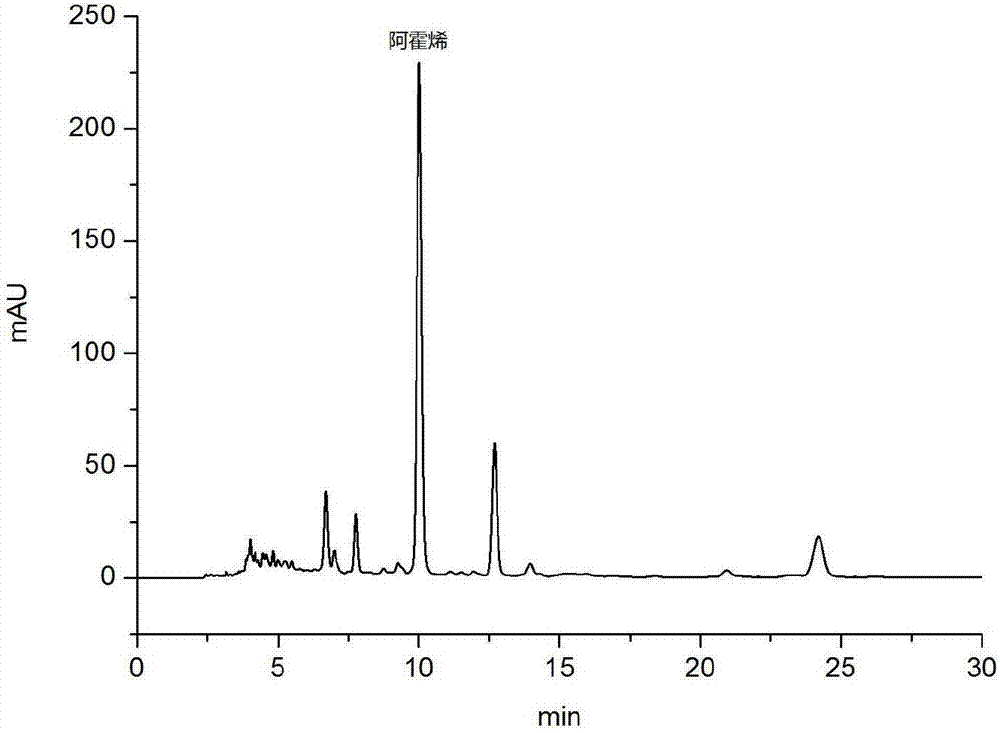

Embodiment 2

[0060] 1, get the garlic 10Kg that produces from Gansu, squeeze the juice with juice extractor after pulverizing, get garlic juice, the yield of garlic juice is 30%.

[0061] 2. Add 6Kg of 0.1% sodium hydroxide solution to the above garlic juice, mix well, place in a temperature-controllable fermenter, adjust the temperature to 10°C, and ferment for 6 days.

[0062] 3. After the mixture has been fermented for 6 days, take the oil in the upper layer of the mixture, add 1000g of rapeseed oil, mix well, and set aside.

[0063] 4. Extract the above-mentioned rapeseed oil mixture with 1000 mL of 95% ethanol, and extract once. The extract is concentrated under reduced pressure at a temperature of 55-75° C. to remove ethanol in the extract to obtain ajoene oil.

[0064] 5. Take UniPS 10-3001Kg, put it into a glass column for chromatography, and load the ajoene oily substance in a dry method.

[0065] 6. Take 5Kg of 40% ethanol to elute the chromatographic column, the elution flow r...

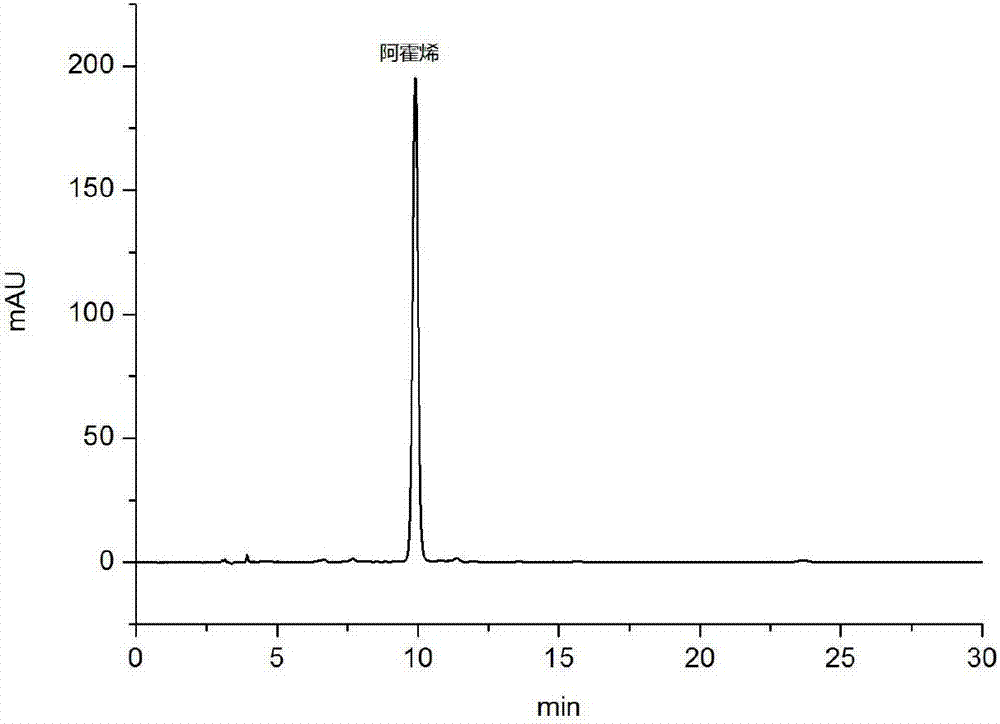

Embodiment 3

[0069] 1, get the garlic 20Kg that produces from Jilin, squeeze the juice with juice extractor after pulverizing, get garlic juice, the yield of garlic juice is 30%.

[0070] 2. Add 1.2Kg of 0.2% dilute hydrochloric acid solution to the above garlic juice, mix well, place in a temperature-controlled fermenter, adjust the temperature to 50°C, and ferment for 1 day.

[0071] 3. After the mixture is fermented for 1 day, take the oil in the upper layer of the mixture, add 250g of linseed oil, mix well, and set aside.

[0072] 4. Extract the above-mentioned linseed oil mixture with 50% ethanol, extract 5 times, 250 mL each time, combine 5 times of 50% ethanol extracts. The extract is concentrated under reduced pressure at a temperature of 55-75° C. to remove ethanol in the extract to obtain ajoene oil.

[0073] 5. Take the macroporous resin AB-82Kg, put it into a glass column for chromatography, and load the ajoene oily substance in a dry method.

[0074] 6. Take 10Kg of 10% etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com