Process for efficiently extracting and utilizing tea leaves

A process and tea technology, which is applied in the field of extraction and preparation of instant tea powder, can solve problems such as strong limitations, and achieve the effects of avoiding oxidation, low production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

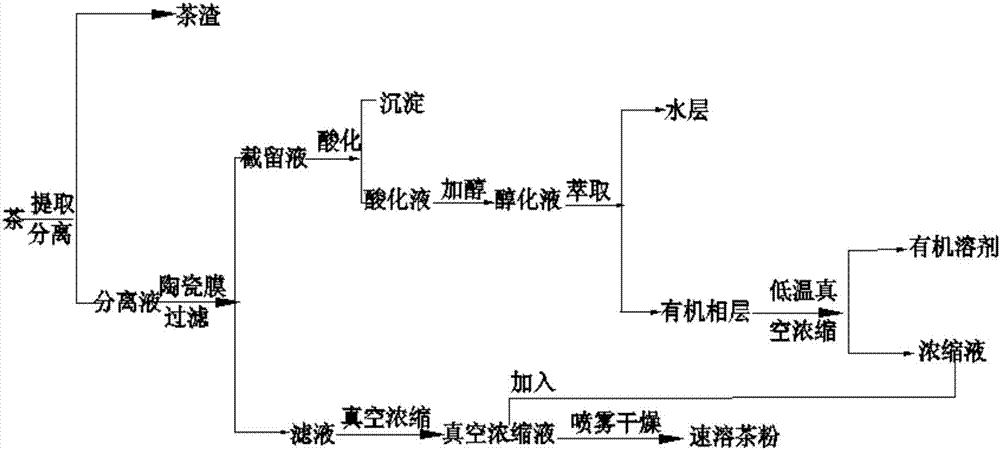

Method used

Image

Examples

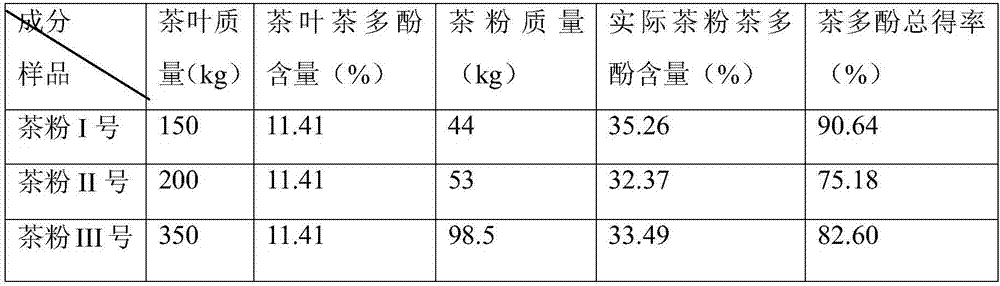

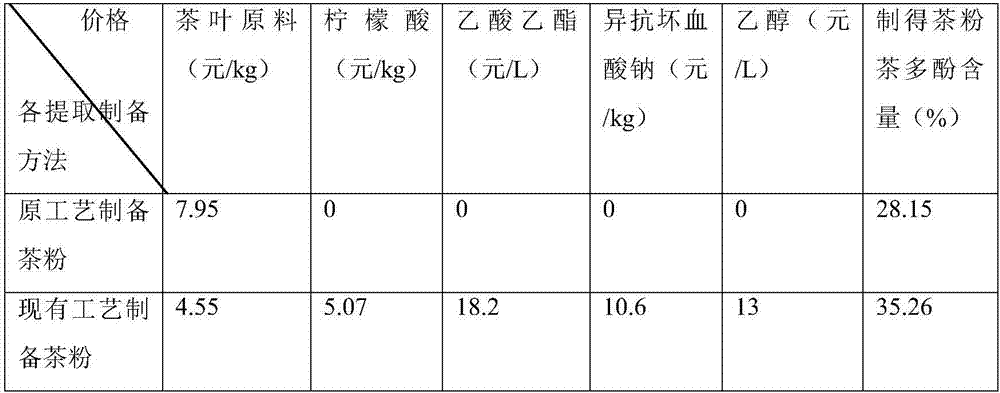

Embodiment 1

[0050] Take 150kg of summer and autumn tea, crush it into powder, add 2250kg of water, extract at 80°C for 30 minutes each time to obtain green tea extract, and then centrifuge to obtain tea dregs and tea liquid. The obtained tea liquid is filtered through a ceramic membrane to obtain 326 kg of clear and translucent filtrate and 123 kg of retentate, and the filtrate was vacuum concentrated to obtain a vacuum concentrate. Add acid and salt to the above-mentioned intercepted solution (citric acid addition: 0.6kg, sodium erythorbate: 0.06kg) for acidification reaction to obtain an acidification solution, add 1.3L ethanol (concentration: 95%) alcoholization to the acidification solution 123L, and obtain the alcoholization solution About 125L was added to 125L ethyl acetate (purity 99%) for extraction, and the organic phase layer was obtained. Concentrate with a multifunctional vacuum concentrator and set the temperature at 40°C to distill off the organic solvent. Add the above conc...

Embodiment 2

[0056] Take 200kg of the same batch of green tea in Example 1, crush it into fine powder, add 3000kg of water, extract at 80°C for 30 minutes each time to obtain a green tea extract, then centrifuge to obtain tea dregs and tea liquid, and the obtained tea liquid Filtrate through a ceramic membrane to obtain 420 kg of clear and translucent filtrate and 167 kg of retentate, and the filtrate is vacuum concentrated to obtain a vacuum concentrate. Add acid and salt to the above-mentioned retentate solution (citric acid addition: 0.8kg, sodium erythorbate 0.08kg) for acidification reaction to obtain acidification solution, add 9L ethanol (concentration 95%) alcoholization to the acidification solution 168L, the obtained alcoholization solution is about 176L was added to 177L ethyl acetate (purity 99%) for extraction, and the organic phase layer obtained was concentrated with a multifunctional vacuum concentrator, and the temperature was set at 40°C to distill the organic solvent, and...

Embodiment 3

[0058] Take 350kg of the same batch of green tea in Example 1, crush it into fine powder, add 5250kg of water, extract at 80°C for 30 minutes each time to obtain a green tea extract, and then centrifuge to obtain tea dregs and tea liquid, and the obtained tea liquid Filtrate through a ceramic membrane to obtain 776 kg of clear and translucent filtrate and 251 kg of retentate, and the filtrate is vacuum concentrated to obtain a vacuum concentrate. Add acid and salt to the above-mentioned intercepted solution (citric acid addition: 1.2kg, sodium erythorbate 0.12kg) for acidification reaction to obtain an acidification solution, and then add 12L of ethanol (concentration 95%) to alcoholize the acidification solution, and the obtained alcoholization solution is about Add 260L of ethyl acetate (purity 99%) to 260L for extraction, obtain the organic phase layer and concentrate it with a multifunctional vacuum concentrator, set the temperature at 40°C to distill the organic solvent, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com