Pre-enzymolysis-extrusion puffing processing technique for increasing water solubility indexes of whole cereal food powder

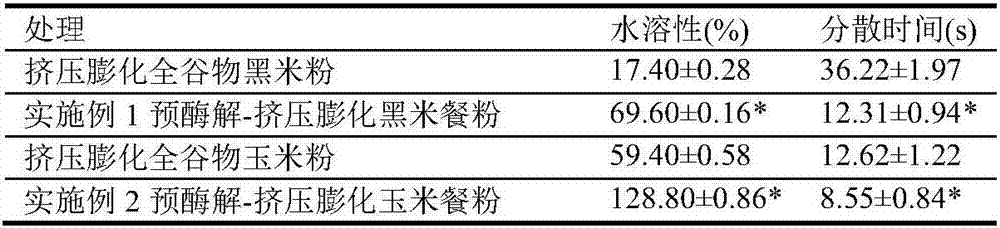

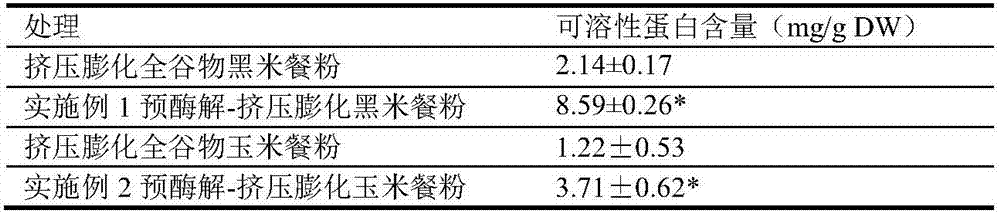

A technology of extrusion puffing and processing technology, which is applied in the field of pre-enzymatic hydrolysis-extrusion puffing processing to improve the water solubility index of whole grain meal powder, and can solve the problems of poor water solubility, high preparation viscosity, and restriction of consumption of whole grain meal powder, etc. , to achieve the effect of good flavor, improved dispersion and fine taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Taking black rice as an example, a pre-enzymolysis-extrusion processing technology for improving the water solubility index of whole grain meal powder includes the following steps:

[0020] S1. Solid-state pre-enzymolysis of whole grain black rice: crush the black rice and pass through a 60-mesh sieve; mix the high-temperature-resistant α-amylase with water evenly, add it to the black rice flour in the form of spray, and mix evenly. The amount of water added is 20% of the dry weight of black rice, and the amount of high-temperature-resistant α-amylase added is 1500U / g of black rice dry weight; the mixture of black rice flour and high-temperature-resistant α-amylase is heated to 100°C in a sandwich pot, Stir slowly while heating, and maintain 15min.

[0021] S2. Enzymolysis-assisted extrusion of whole-grain black rice: The pre-enzymolysis black rice flour was transported to the feed hopper of a twin-screw extrusion extruder, the extrusion temperature was set at 150°C, an...

Embodiment 2

[0024] Taking corn as an example, a whole grain meal powder pre-enzymolysis-extrusion method includes the following steps:

[0025] S1. Solid-state pre-enzymolysis of whole grain corn: crush the corn and pass through a 60-mesh sieve; mix the high-temperature-resistant α-amylase with water evenly, add it to corn flour in the form of spray, and mix evenly. The moisture content is 10% of the dry weight of corn, and the amount of high-temperature-resistant α-amylase added is 500U / g dry weight of corn; use a sandwich pot to heat the mixture of corn flour and high-temperature-resistant α-amylase to 90°C, and slowly Stir and maintain for 30min.

[0026] S2. Enzymolysis-assisted extrusion and expansion of whole grain corn: the pre-enzymolysis corn flour is sent to the feed hopper of the twin-screw extrusion extruder, the outlet temperature is set to 110°C, and the screw speed is 25Hz.

[0027] S3. Drying and crushing of the whole grain corn extrudate: the extrudate was dried with hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com