Preparation method for core-shell carbon-coated iron nanocomposite material

A composite material, carbon coating technology, applied in nanotechnology, transportation and packaging, metal processing equipment, etc., can solve the problems of difficult separation of products, high raw material requirements, long preparation cycle, etc., to achieve excellent electrical and magnetic properties, The effect of wide range of raw materials and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation process of the core-shell carbon-coated iron nanocomposite material of this embodiment is as follows:

[0036] Weigh 1.30g of ferrocene, 14.70g of benzene and 2.30g of short nickel rods with an electronic balance, dissolve ferrocene in benzene to make a mixed solution of a certain proportion, then ultrasonically disperse the mixed solution, mix well and add Discharge medium short nickel rod.

[0037] The quartz reactor that above-mentioned mixture is housed is placed in industrial microwave oven, feeds inert gas Ar in reactor to get rid of air, and argon flow rate is 200ml / min, and the power of industrial microwave oven is set to 1800W, and reaction time is set to 5min, Start the industrial microwave oven.

[0038] After the reaction, keep the argon flow rate constant, and continue to flow argon for 5 minutes, then cool the reactor to room temperature naturally, take out the reaction product, grind it lightly, and screen out the discharge medium to obta...

Embodiment 2

[0042] Weigh 1.30g of ferrocene, 14.70g of benzene and 1.90g of iron filings with an electronic balance, dissolve ferrocene in benzene to make a mixed solution of a certain proportion, then ultrasonically disperse the mixed solution, mix well and then add the discharge Medium filings.

[0043]The quartz reactor that above-mentioned mixture is housed is placed in industrial microwave oven, feeds inert gas Ar in reactor to get rid of air, and argon flow rate is 200ml / min, and the power of industrial microwave oven is set to 1800W, and reaction time is set to 5min, Start the industrial microwave oven.

[0044] After the reaction, keep the argon flow rate constant, and continue to flow argon for 5 minutes, then cool the reactor to room temperature naturally, take out the reaction product, grind it lightly, and screen out the discharge medium to obtain the core-shell carbon-coated iron nanometer composite material.

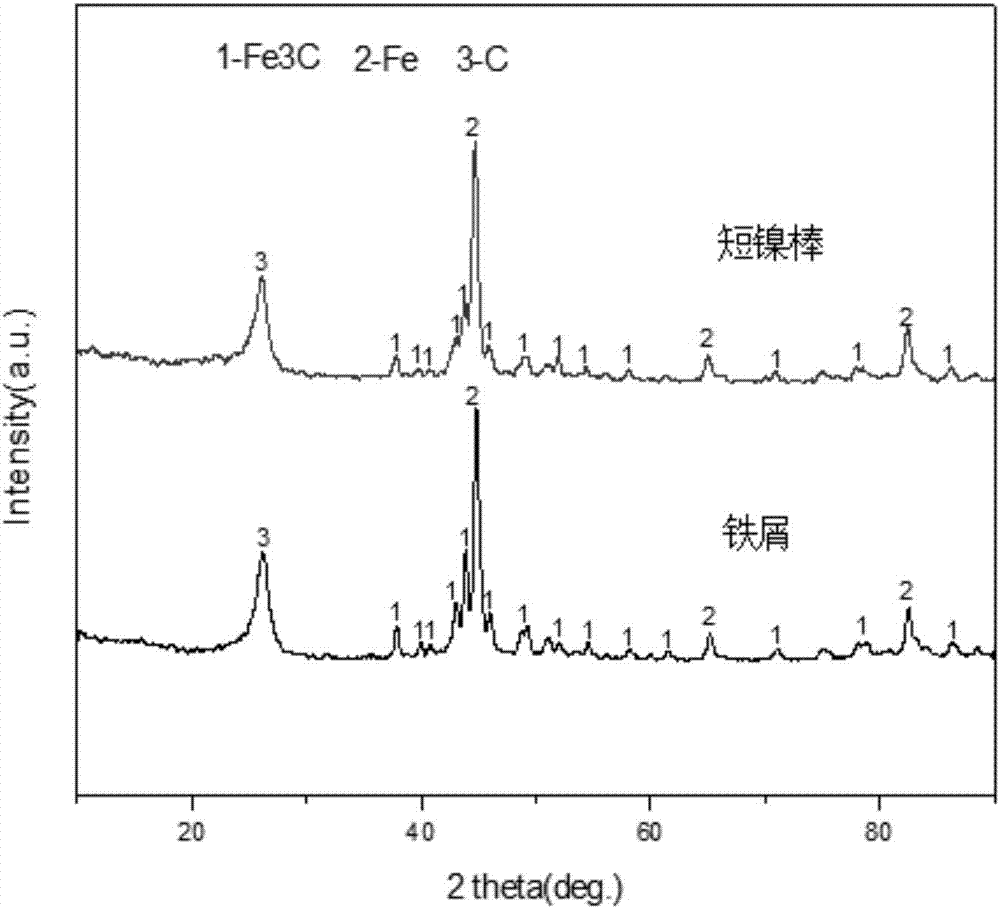

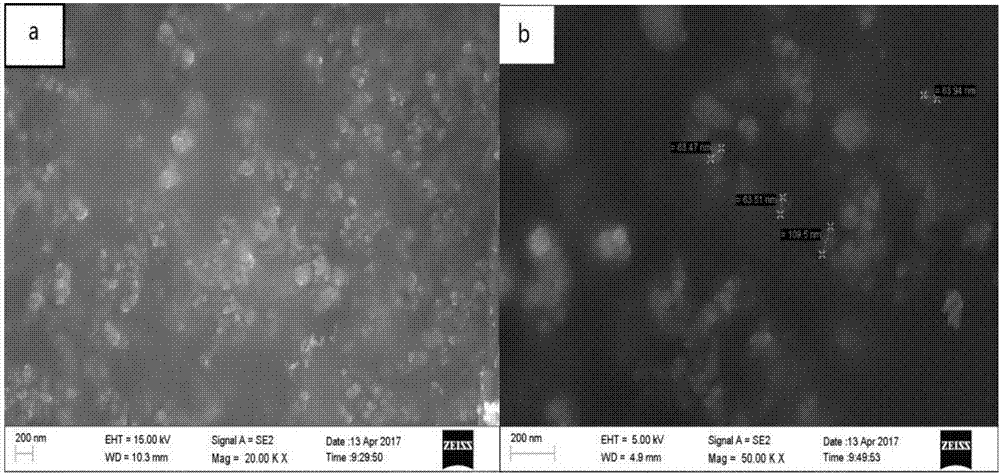

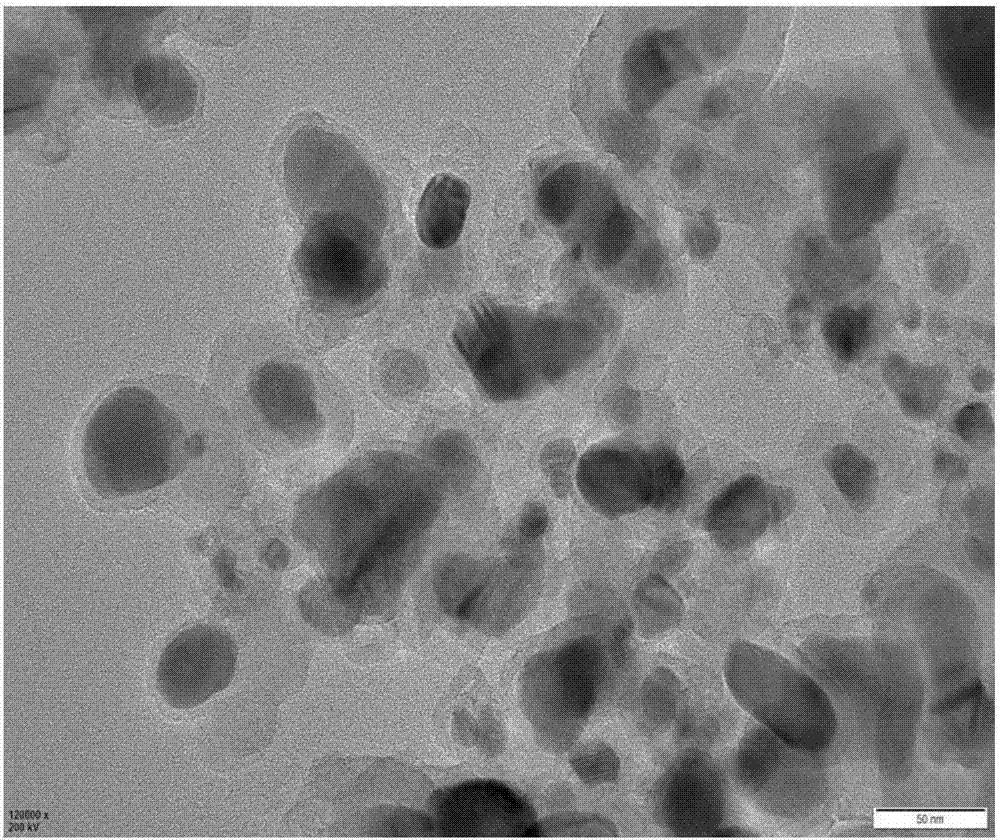

[0045] figure 1 The XRD patterns of the core-shell carbon-coat...

Embodiment 3

[0047] Weigh 1.30g of ferrocene, 14.70g of benzene and 2.30g of short nickel rods with an electronic balance, dissolve ferrocene in benzene to make a mixed solution of a certain proportion, then ultrasonically disperse the mixed solution, mix well and add Discharge medium short nickel rod.

[0048] The quartz reactor that above-mentioned mixture is housed is placed in industrial microwave oven, feeds inert gas Ar in reactor to get rid of air, and argon flow rate is 200ml / min, and the power of industrial microwave oven is set to 1500W, and reaction time is set to 5min, Start the industrial microwave oven.

[0049] After the reaction, keep the argon flow rate constant, and continue to flow argon for 5 minutes, then cool the reactor to room temperature naturally, take out the reaction product, grind it lightly, and screen out the discharge medium to obtain the core-shell carbon-coated iron nanometer composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com