Thermal insulation material and preparation method thereof

A technology of thermal insulation materials and raw materials, which is applied in the field of building materials to achieve the effects of good thermal insulation, good fire prevention effect, and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

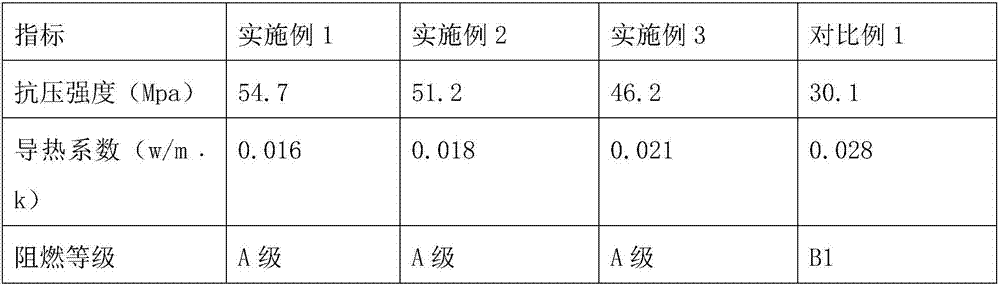

Examples

Embodiment 1

[0040] A thermal insulation material, comprising the following raw materials in parts by weight: 25 parts of granite powder, 18 parts of aluminum silicate powder, 10 parts of rock wool, 6.5 parts of glass fiber, 17 parts of quartz sand, 28 parts of gravel, 28 parts of cement, bentonite 23 parts, 21 parts of glass beads, 18 parts of airgel, 28 parts of expanded perlite, 19 parts of nano-silicon carbide, 18 parts of magnesium oxide, 22 parts of vermiculite, 0.7 parts of retarder, 0.5 parts of air-entraining agent, expansion 0.4 parts of water reducing agent, 0.5 parts of water reducing agent and 10 parts of water.

[0041] Ceramic fibers are added to the raw materials. Ceramic fibers have the characteristics of light weight, high temperature resistance, good thermal stability, good fire resistance, good thermal insulation and high mechanical strength, which help to improve the fire resistance and mechanical properties of the prepared insulation materials. strength.

[0042] Gla...

Embodiment 2

[0059] A thermal insulation material, comprising the following raw materials in parts by weight: 20 parts of granite powder, 15 parts of aluminum silicate powder, 7 parts of rock wool, 4 parts of ceramic fiber, 13 parts of quartz sand, 22 parts of gravel, 15 parts of cement, bentonite 15 parts, 15 parts of glass microspheres, 13 parts of airgel, 21 parts of expanded perlite, 16 parts of nano-silicon carbide, 12 parts of magnesium oxide, 19 parts of vermiculite, 0.5 parts of retarder, 0.4 parts of air-entraining agent, expansion 0.3 parts of agent, 0.3 parts of water reducing agent and 8 parts of water.

[0060] Ceramic fibers are added to the raw materials. Ceramic fibers have the characteristics of light weight, high temperature resistance, good thermal stability, good fire resistance, good thermal insulation and high mechanical strength, which help to improve the fire resistance and mechanical properties of the prepared insulation materials. strength.

[0061] Glass microsp...

Embodiment 3

[0078] A thermal insulation material, comprising the following raw materials in parts by weight: 30 parts of granite powder, 21 parts of aluminum silicate powder, 13 parts of rock wool, 9 parts of ceramic fiber, 21 parts of quartz sand, 36 parts of gravel, 21 parts of cement, bentonite 31 parts, 27 parts of glass beads, 23 parts of airgel, 35 parts of expanded perlite, 22 parts of nano-silicon carbide, 24 parts of magnesium oxide, 25 parts of vermiculite, 0.9 parts of retarder, 0.6 parts of air-entraining agent, expansion 0.5 parts of water reducing agent, 0.7 parts of water reducing agent and 12 parts of water.

[0079] Ceramic fibers are added to the raw materials. Ceramic fibers have the characteristics of light weight, high temperature resistance, good thermal stability, good fire resistance, good thermal insulation and high mechanical strength, which help to improve the fire resistance and mechanical properties of the prepared insulation materials. strength.

[0080] Gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com