Low-foam laundry soap with strong dirty removal capacity

A laundry soap, manual technology, applied in the directions of surface active detergent compositions, surface active non-soap compounds and cleaning compositions, detergent compositions, etc. Less problems, to achieve the effect of increasing decontamination ability, good emulsifying performance and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

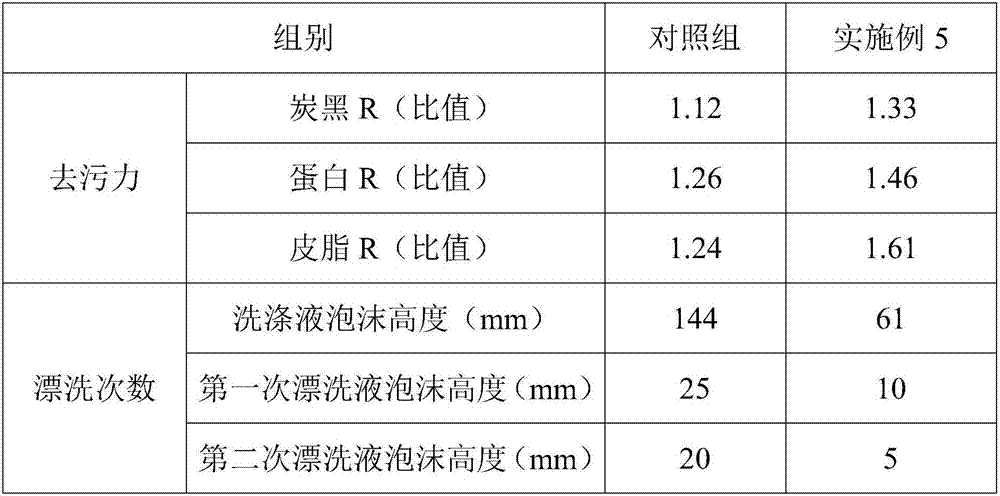

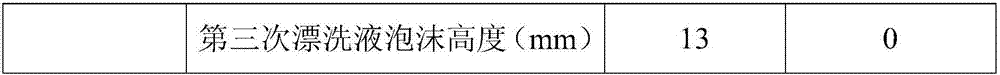

Examples

Embodiment 1

[0017] A handmade laundry soap with strong detergency and low foam, its raw materials include by weight: 10 parts of sodium hydroxide, 25 parts of water, 48 parts of palm oil, 11 parts of coconut oil, 45 parts of surfactant, 7 parts of defoamer , 1.5 parts of chelating agent, 2 parts of natron, 3 parts of biological enzyme, 4 parts of fungicide;

[0018] Among them, the raw materials of the surfactant include: Tween 80, alkyl glycoside sugar, sodium dodecylbenzenesulfonate, lauryl amidopropyl betaine.

Embodiment 2

[0020] A handmade laundry soap with strong detergency and low foam, its raw materials include by weight: 8 parts of sodium hydroxide, 30 parts of water, 40 parts of palm oil, 12 parts of coconut oil, 35 parts of surfactant, 8 parts of emulsified silicone oil, 1 part of iminodisuccinic acid, 3 parts of natron, 2 parts of biological enzyme, 5 parts of fungicide;

[0021] Among them, the raw materials of the surfactant include: Tween 80, alkyl glycosides, sodium dodecylbenzenesulfonate, lauryl amidopropyl betaine, wherein, Tween 80, alkyl glycosides, dodecyl The weight ratio of sodium benzenesulfonate to lauryl amidopropyl betaine is 0.2:4:1:1;

[0022] The biological enzyme is a mixture of amylase and protease;

[0023] The raw materials of the bactericide include by weight: 1 part of tea tree essential oil, 4 parts of chamomile essential oil, and 3 parts of Folium folium extract;

[0024] During the preparation of the Folium Folium extract, pulverize Folium Folium Folium, add...

Embodiment 3

[0026] A kind of handmade laundry soap with strong detergency and low foam, its raw materials include by weight: 12 parts of sodium hydroxide, 20 parts of water, 55 parts of palm oil, 10 parts of coconut oil, 55 parts of surfactant, 6 parts of emulsified silicone oil, 2 parts of iminodisuccinic acid, 1 part of natron, 4 parts of biological enzyme, 3 parts of fungicide;

[0027] Among them, the raw materials of the surfactant include: Tween 80, alkyl glycosides, sodium dodecylbenzenesulfonate, lauryl amidopropyl betaine, wherein, Tween 80, alkyl glycosides, dodecyl The weight ratio of sodium benzenesulfonate to lauryl amidopropyl betaine is 0.4:2:1.5:0.5;

[0028] The biological enzyme is a mixture of amylase and protease;

[0029] The raw materials of the bactericide include by weight: 2 parts of tea tree essential oil, 2 parts of chamomile essential oil, and 5 parts of Folium folium extract;

[0030] During the preparation of the Folium Folium extract, pulverize Folium Foli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com