Infrared stealth biomimetic material and preparation method thereof

A bionic material and infrared technology, applied in textiles and papermaking, etc., can solve the problems of short infrared stealth time, narrow temperature control range, inability to realize background adaptive infrared fusion, etc., and achieve adaptive infrared fusion and reduced moisture permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

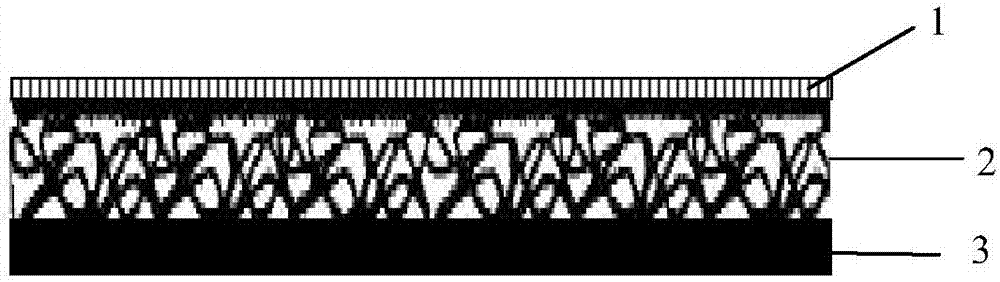

[0021] A preparation method of an infrared stealth bionic material, comprising the following steps:

[0022] (1) Configure the porous and breathable skin layer emulsion according to the components listed in Example 1 in Table 1 and their mass fractions: the surface layer polyurethane resin is a hydrolysis-resistant polyurethane surface layer resin solution, and the 100% modulus is 40Mpa ; The porogen is polyethylene glycol 200; The soft segment is polyolefin polyol; The hard segment is polyisocyanate.

[0023] (2) According to the components listed in Table 1 and their mass fractions, foam together on waterproof and heat-insulating cloth (0.2mm thick) to prepare a water absorption / water retention and moisture transmission layer, with a thickness of 5mm; the temperature for co-foaming is 120°C, the time is 5h.

[0024] (3) Spray the porous breathable skin layer emulsion obtained in step (1) on the water absorption / water retention and moisture transmission layer obtained in ste...

Embodiment 2

[0026] A preparation method of an infrared stealth bionic material, comprising the following steps:

[0027] (1) According to the components listed in Example 1 in Table 1 and their mass parts, the porous and breathable skin layer emulsion is configured: the surface layer polyurethane resin is a hydrolysis-resistant polyurethane surface layer resin solution, and the 100% modulus is 60Mpa; The porogen is polyethylene glycol 200; the soft segment is polyolefin polyol; and the hard segment is polyisocyanate.

[0028] (2) According to the components listed in Table 1 and their mass fractions, foam together on waterproof and heat-insulating cloth (0.4mm thick) to prepare a water absorption / water retention and moisture transmission layer with a thickness of 6mm; the temperature for co-foaming is 110°C, the time is 4.5h.

[0029] (3) Spray the porous breathable skin layer emulsion obtained in step (1) on the water absorption / water retention and moisture transmission layer obtained i...

Embodiment 3

[0031] A preparation method of an infrared stealth bionic material, comprising the following steps:

[0032] (1) Configure the porous and breathable skin layer emulsion according to the components listed in Example 1 in Table 1 and their mass fractions: the surface layer polyurethane resin is a hydrolysis-resistant polyurethane surface layer resin solution, and the 100% modulus is 80Mpa ; The porogen is polyethylene glycol 200; The soft segment is polyolefin polyol; The hard segment is polyisocyanate.

[0033] (2) According to the components listed in Table 1 and their mass fractions, the water absorption / water retention and moisture transmission layer is prepared by co-foaming on the waterproof and heat-insulating cloth (0.6mm thick), with a thickness of 8mm; the co-foaming temperature is 100°C, the time is 4h.

[0034] (3) Spray the porous breathable skin layer emulsion obtained in step (1) on the water absorption / water retention and moisture transmission layer obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com