Perovskite light absorbing material and preparation method thereof

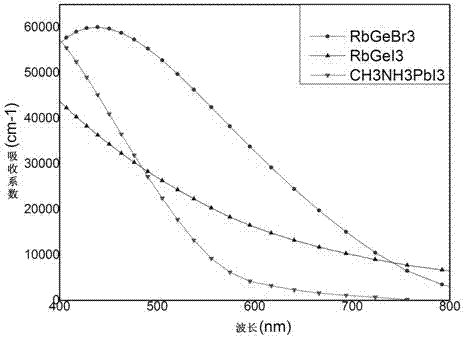

A light absorbing material and perovskite technology, applied in the field of materials, can solve the problems of poor film formation quality and easy oxidation, and achieve the effects of reducing toxicity, increasing light absorption coefficient, and pollution-free environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: RbGeBr 3 The preparation method of perovskite light-absorbing material specifically comprises the following steps:

[0019] (1) GeO 2 Join in hydrobromic acid solution to obtain acid solution A, wherein the concentration of hydrobromic acid solution is 6mol / L, Ge in acid solution A 4+ The ion concentration is 0.015mol / L;

[0020] (2) At a temperature of 95°C, add hypophosphorous acid solution to solution A obtained in step (1) and react for 8 minutes, wherein the concentration of hypophosphorous acid solution is 0.0182mol / mL, and the volume ratio of solution A to hypophosphorous acid solution 10.5:1;

[0021] (3) At a temperature of 95°C, add rubidium salt (rubidium bromide is rubidium bromide) to the reaction solution obtained in step (2) and react for 8 minutes, wherein the rubidium salt (rubidium bromide) and GeO 2 The molar ratio is 1:1, solid-liquid separation, washing, drying to obtain RbGeBr 3 Perovskite light-absorbing materials;

[0022] The Rb...

Embodiment 2

[0023] Example 2: RbGeI 3 The preparation method of perovskite light-absorbing material specifically comprises the following steps:

[0024] (1) GeO 2 Join in the hydroiodic acid solution to obtain acid solution A, wherein the concentration of the hydroiodic acid solution is 8mol / L, Ge in the acid solution A 4+ The ion concentration is 0.013mol / L;

[0025] (2) At a temperature of 100°C, add hypophosphorous acid solution to solution A obtained in step (1) and react for 10 minutes, wherein the concentration of hypophosphorous acid solution is 0.0184 mol / mL, and the volume ratio of solution A to hypophosphorous acid solution is 9.5:1;

[0026] (3) At a temperature of 100°C, add rubidium salt (rubidium iodide is rubidium iodide) to the reaction solution obtained in step (2) and react for 10 minutes, wherein the rubidium salt (rubidium iodide) and GeO 2 The molar ratio is 1:1, solid-liquid separation, washing, drying to get RbGeI 3 Perovskite light-absorbing materials;

[002...

Embodiment 3

[0028] Example 3: RbGeBr 3 The preparation method of perovskite light-absorbing material specifically comprises the following steps:

[0029] (1) GeO 2 Join in hydrobromic acid solution to obtain acid solution A, wherein the concentration of hydrobromic acid solution is 7mol / L, Ge in acid solution A 4+ The ion concentration is 0.014mol / L;

[0030] (2) At a temperature of 96°C, add hypophosphorous acid solution to solution A obtained in step (1) and react for 8 minutes, wherein the concentration of hypophosphorous acid solution is 0.0183mol / mL, the volume ratio of solution A to hypophosphorous acid solution 9.8:1;

[0031] (3) At a temperature of 96°C, add rubidium salt (rubidium bromide) to the reaction solution obtained in step (2) and react for 9 minutes, wherein the rubidium salt (rubidium bromide) and GeO 2 The molar ratio is 1:1, solid-liquid separation, washing, drying to obtain RbGeBr 3 Perovskite light-absorbing materials;

[0032] The RbGeBr prepared in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com