Cu/TiO2-NB nano porous ceramic film, and preparation method and application of nano porous ceramic film

A nanoporous, ceramic membrane technology, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., to improve visible light catalytic activity, improve separation performance, and solve biological swelling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A Cu / TiO 2 -The preparation method of NB nanoporous ceramic membrane, the steps are as follows:

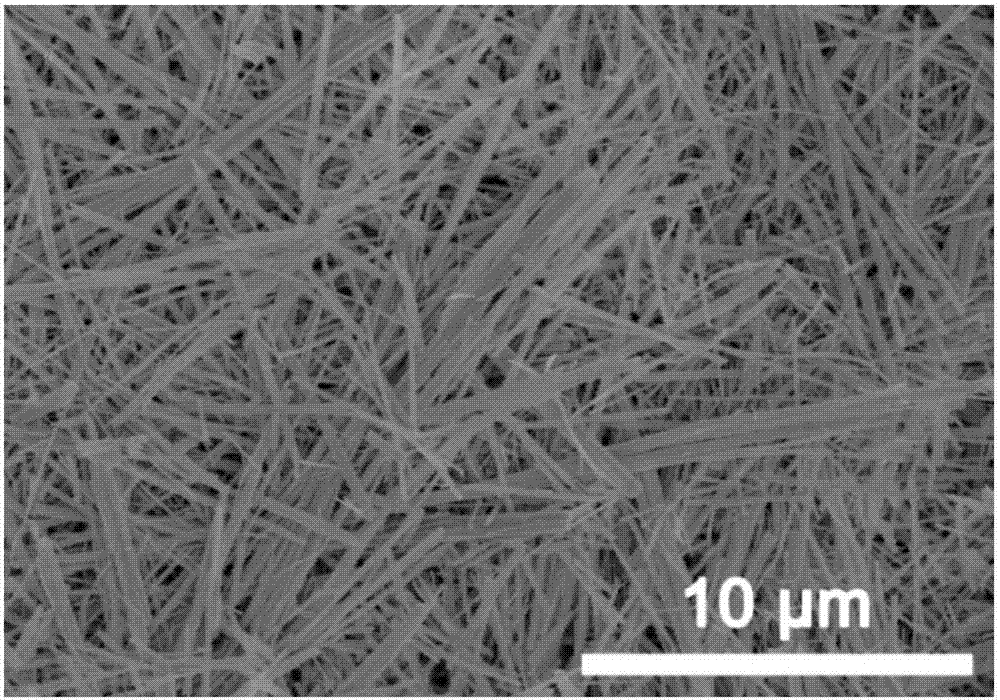

[0039] (1) Disperse 2.4g of titanium dioxide (P25) evenly in 480mL of sodium hydroxide solution with a concentration of 10mol / L, and react with alkali heat in a constant temperature drying oven at 200°C for 72h to obtain sodium titanate nanobelts, and then place the sample in 1000mL concentration is acidified 24h in the hydrochloric acid solution of 0.1M, obtains titanic acid nanobelt, the scanning electron microscope SEM photo of the obtained titanic acid nanobelt is as follows figure 1 shown.

[0040] (2) Take 0.1 g of the above-mentioned titanate nanobelts in a circulating sleeve containing 100 mL of deionized water, and ultrasonically disperse to obtain a uniformly dispersed suspension, and then add 800 μL of Cu(CH 3 COO) 2 solution, continue to avoid light and stir for 2h, then adjust the pH to 8.5 with urea solution, age at 80°C for 4h, then suction filter, wash wi...

Embodiment 2

[0044] A Cu / TiO 2 -The preparation method of NB nanoporous ceramic membrane, as shown in embodiment 1, difference is:

[0045] Step (2) Take 0.1 g of titanate nanobelts in step (1) in a circulation sleeve containing 100 mL of deionized water, ultrasonically disperse to obtain a uniformly dispersed suspension, and then add Cu(CH 3 COO) 2 solution, continue to avoid light and stir for 2h, then adjust the pH to 8.5 with urea solution, age at 80°C for 4h, then suction filter, wash with water, dry and H 2 Reductive pretreatment to obtain Cu / TiO with 1 wt% copper loading 2 nanobelt.

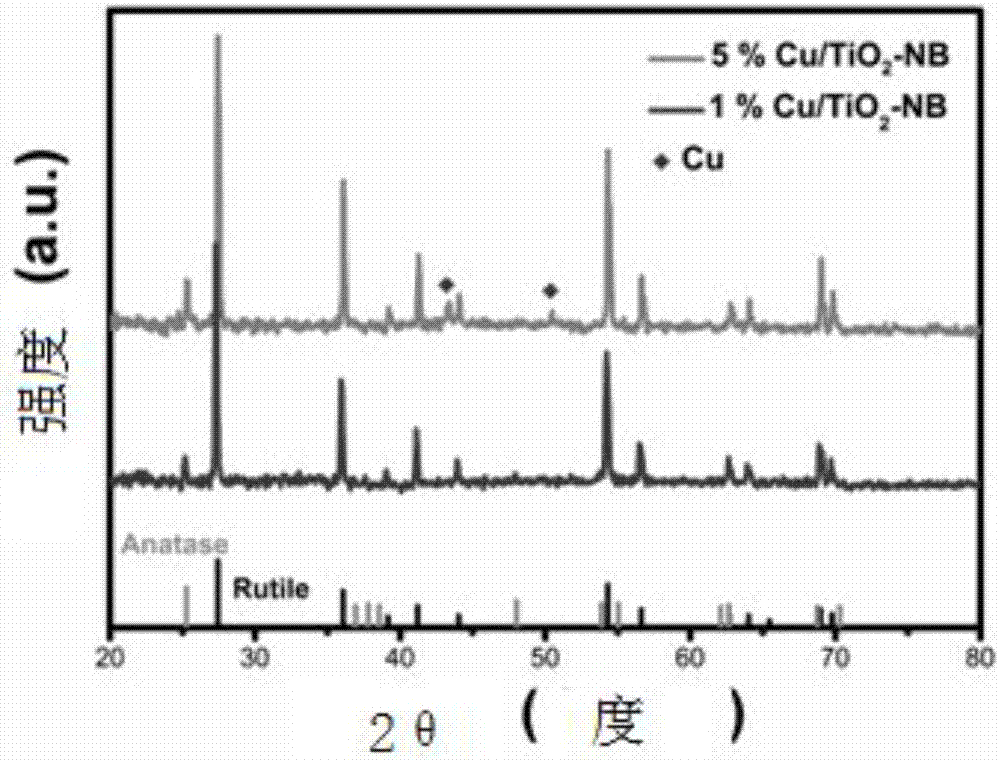

[0046] The XRD pattern of the nanoporous ceramic membrane obtained by pressing and calcining is as follows image 3 shown by image 3 It can be seen that Example 1 and Example 2 show that copper is successfully loaded in the ceramic film. With the increase of copper loading (Example 2), the characteristic peak of the metal copper in the ceramic film is more obvious, and exists as metallic copper. ...

Embodiment 3

[0048] A Cu / TiO 2 -The preparation method of NB nanoporous ceramic membrane, as shown in embodiment 1, difference is:

[0049] Step (2) Take 0.1 g of titanate nanobelts in step (1) in a circulation sleeve containing 100 mL of deionized water, ultrasonically disperse to obtain a uniformly dispersed suspension, and then add Cu(CH 3 COO) 2 solution, continue to avoid light and stir for 2h, then adjust the pH to 8.5 with urea solution, age at 80°C for 4h, then suction filter, wash with water, dry and H 2 Reductive pretreatment to obtain Cu / TiO with 8 wt% copper loading 2 nanobelt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com