Method for preparing high-specific surface area tin dioxide catalyst by using mesoporous silicon dioxide as hard template

A technology of mesoporous silica and high specific surface, applied in the field of environmental protection and air pollution control, can solve the problems of complex and cumbersome preparation process, cumbersome preparation process steps, waste of copper oxide resources, etc., and achieve wide source of materials and simple steps Easy to do, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

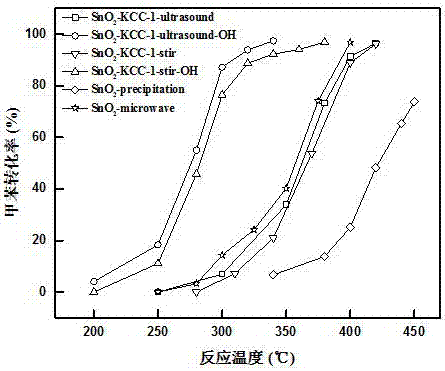

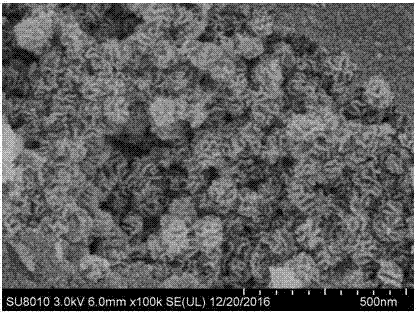

[0025] 20 g SnCl 4 ·5H 2 O was dissolved in 400 mL deionized water and stirred for 30 minutes. Then 0.5 g of KCC-1 mesoporous silica was added and stirring was continued for 30 minutes. The above mixed solution was transferred to a quartz flask, and reacted for 30 minutes under the conditions of microwave power 800 W and stirring speed 600 r / min. The precipitate was washed by centrifugation with deionized water until the eluate TDS 2 - KCC-1-Stir catalyst. The specific surface area of the catalyst was measured to be 352 m 2 / g.

Embodiment 2

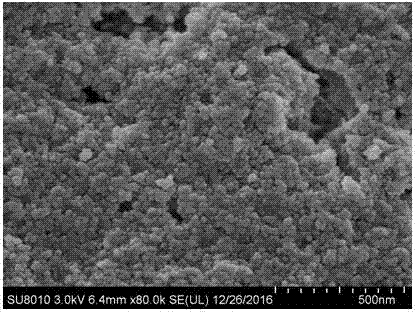

[0027] 20 g SnCl 4 ·5H 2 O was dissolved in 400 mL deionized water and stirred for 30 minutes. Subsequently, 0.5 g of KCC-1 mesoporous silica was added and sonicated for 30 min. The above mixed solution was transferred to a quartz flask, and reacted for 30 minutes under the conditions of microwave power 800 W and ultrasonic power 500 W. The precipitate was washed by centrifugation with deionized water until the eluate TDS 2 - KCC-1-Ultra catalyst. The specific surface area of the catalyst was measured to be 135 m 2 / g.

Embodiment 3

[0029] Take 1 g of Catalyst 1 and add it into an appropriate amount of 10 mol / L NaOH solution, and place it in a water bath at 70°C for 5 h under the condition of continuous magnetic stirring. The precipitate was washed by centrifugation with deionized water until the eluate TDS 2 - KCC-1-Stir-OH catalyst. The specific surface area of the catalyst was measured to be 146 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com