Equipment and treatment method for treating dye wastewater by electrochemical-adsorption process

The technology of dye wastewater and composite process is applied in the equipment and treatment field of electrochemical-adsorption composite process to treat dye wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

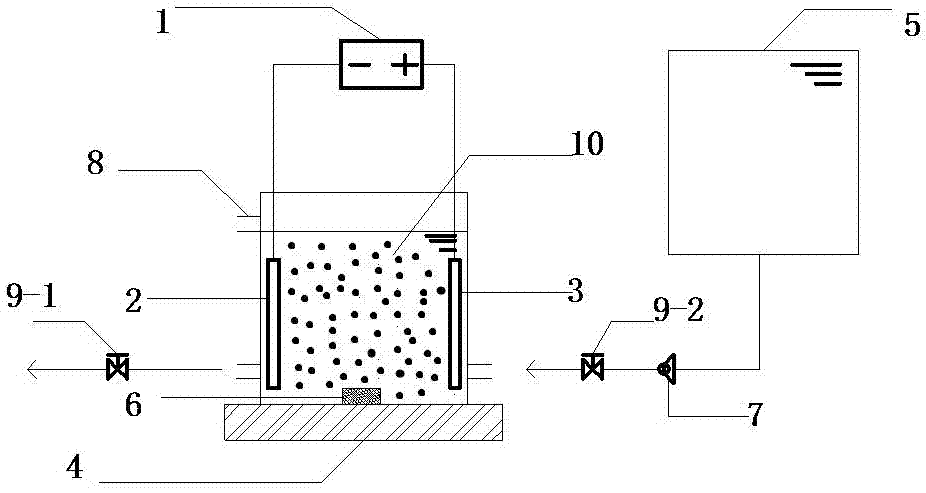

[0032] Such as figure 1 As shown, an electrochemical-adsorption composite process is used to treat dye wastewater, which consists of a DC stabilized power supply 1, a graphite plate cathode 2 loaded with metal copper and palladium, a ruthenium tin-coated titanium anode 3, a magnetic stirrer 4, and a wastewater storage tank 5. Magnetic stirrer 6, peristaltic pump 7, overflow port 8, water outlet valve 9-1, water inlet valve 9-2 and powdered activated carbon 10, the graphite plate cathode 2 loaded with metal copper palladium is made of ethylene glycol Prepared by the reduction method, take the graphite plate electrode, sand the surface smooth and flat, soak it in NaOH solution and hydrochloric acid solution in turn, rinse and dry to prepare the prepared graphite plate electrode, put the prepared prepared graphite plate electrode in ethylene glycol solution, ultrasonic 1h; weigh 76mg of PdCl 2 , 72mg of CuCl 2 . 2H 2The sodium citrate of 0 and 240mg is in the 250mL round-bott...

Embodiment 2

[0039] Such as figure 1 As shown, an electrochemical-adsorption composite process is used to treat dye wastewater, which consists of a DC stabilized power supply 1, a graphite plate cathode 2 loaded with metal copper and palladium, a ruthenium tin-coated titanium anode 3, a magnetic stirrer 4, and a wastewater storage tank 5. Magnetic stirrer 6, peristaltic pump 7, overflow port 8, water outlet valve 9-1, water inlet valve 9-2 and powdered activated carbon 10, the pool of the equipment for treating dye wastewater by the electrochemical-adsorption composite process The body is a cuboid with a size of 15cm*10cm*12cm. The graphite plate cathode 2 loaded with metal copper palladium and the ruthenium-tin-coated titanium anode 3 are respectively arranged at both ends of the pool body of the equipment for treating dye wastewater by electrochemical-adsorption composite process , the graphite plate cathode 2 loaded with metal copper and palladium is prepared by the ethylene glycol redu...

Embodiment 3

[0046] Such as figure 1 As shown, an electrochemical-adsorption composite process is used to treat dye wastewater, which consists of a DC stabilized power supply 1, a graphite plate cathode 2 loaded with metal copper, a ruthenium tin-coated titanium anode 3, a magnetic stirrer 4, and a wastewater storage tank 5 , a magnetic stirrer 6, a peristaltic pump 7, an overflow port 8, a water outlet valve 9-1, a water inlet valve 9-2 and powdered activated carbon 10, the pool body of the equipment for treating dye wastewater by the electrochemical-adsorption composite process It is a cuboid with a size of 15cm*10cm*12cm. The graphite plate cathode 2 and the ruthenium-tin-coated titanium anode 3 loaded with metal copper and palladium are respectively arranged at both ends of the pool body of the equipment for treating dye wastewater by electrochemical-adsorption composite process. The graphite plate cathode 2 loaded with metal copper and palladium is obtained by the ethylene glycol redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com