Preparation method of multifunctional mimic enzyme composite sphere and application thereof

A technology of simulating enzymes and composite balls, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of weakened catalytic activity, easily destroyed structure, low catalytic activity, etc., and achieve recycling Easy and fast operation, low cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

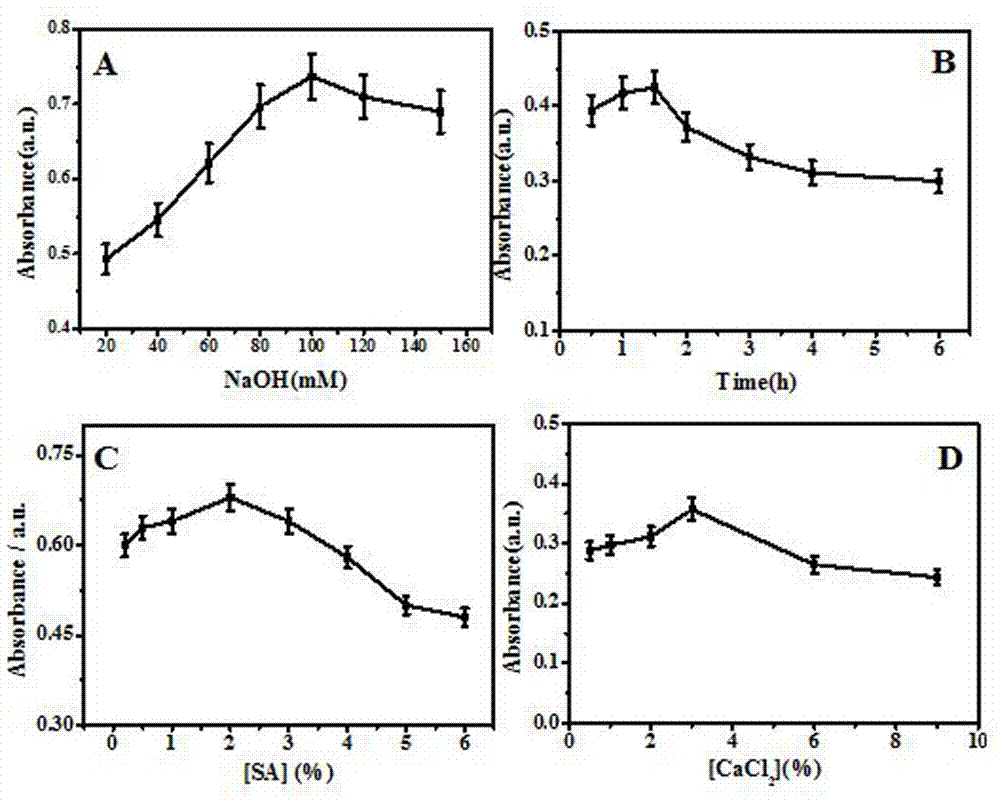

[0040] A preparation method of a multifunctional imitation enzyme composite ball, the proportioning ratio of each raw material is as follows:

[0041] HAuCl 4 : 10.0 mM, 1.0 mL

[0042] Hemin: 0.25 mg mL -1 , 1.0 mL

[0043] NaOH: 1.0 M, 105 μL

[0044] SG: 5.0mg

[0045] SA: 0.5 wt%, 1.0 mL

[0046] Fe 3 o 4 : 15.0 mg

[0047] CaCl 2 : 1.0 wt %, 20.0 mL

[0048] The steps are:

[0049] 1) At room temperature, the FeCl 3 ·6H 2 O (1.73 g ) was dissolved in ethylene glycol (35 mL) with a concentration of 0.183M, stirred by magnetic force, and after it was completely dissolved, 3.83 g of sodium acetate was added, the sodium acetate was 0.804 M in the solution, continued to stir for 30 min and then transferred to high pressure In the still, adjust the temperature to 200 °C, react for 8 h, then cool to room temperature, separate with a magnet, collect the solid adsorbed by the magnet, wash with water and ethanol, and dry at 60 °C for 12 h to obtain hollow nanospheres F...

Embodiment 2

[0053] A preparation method of a multifunctional imitation enzyme composite ball, the proportioning ratio of each raw material is as follows:

[0054] HAuCl 4 : 10 mM, 1.0 mL

[0055] Hemin: 0.60 mg mL -1 , 1.0 mL

[0056] NaOH: 1.0 M, 115 μL

[0057] SG: 10.0mg

[0058] SA: 1.0 wt%, 1.0 mL

[0059] Fe 3 o 4 : 25 mg

[0060] CaCl 2 : 1.5 wt%, 20 mL

[0061] The steps are:

[0062] 1) At room temperature, the FeCl 3 ·6H 2 O (1.73 g ) was dissolved in ethylene glycol (35 mL) with a concentration of 0.183M, stirred by magnetic force, and after it was completely dissolved, 3.83 g of sodium acetate was added, the sodium acetate was 0.804 M in the solution, continued to stir for 30 min and then transferred to high pressure In the still, adjust the temperature to 200 °C, react for 8 h, then cool to room temperature, separate with a magnet, collect the solid adsorbed by the magnet, wash with water and ethanol, and dry at 60 °C for 12 h to obtain hollow nanospheres Fe 3 o...

Embodiment 3

[0066] A preparation method of a multifunctional imitation enzyme composite ball, the proportioning ratio of each raw material is as follows:

[0067] HAuCl 4 : 10.0 mM, 1.0 mL

[0068] Hemin: 1.0 mg mL -1 , 1.0 mL

[0069] NaOH: 1.0 M, 125 μL

[0070] SG: 12.0mg

[0071] SA: 2.5w%, 1.0mL

[0072] Fe 3 o 4 : 35.0 mg

[0073] CaCl 2 : 3.0w%, 20mL

[0074] The steps are:

[0075] 1) At room temperature, the FeCl 3 ·6H 2 O (1.73 g ) was dissolved in ethylene glycol (35 mL) with a concentration of 0.183M, stirred by magnetic force, and after it was completely dissolved, 3.83 g of sodium acetate was added, the sodium acetate was 0.804 M in the solution, continued to stir for 30 min and then transferred to high pressure In the still, adjust the temperature to 200 °C, react for 8 h, then cool to room temperature, separate with a magnet, collect the solid adsorbed by the magnet, wash with water and ethanol, and dry at 60 °C for 12 h to obtain hollow nanospheres Fe 3 o 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com