Over-wall high-elasticity joint material for steel bridge deck pavement maintenance and preparation method and use method of over-wall high-elasticity joint material

A steel bridge deck and pavement technology, which is applied to bridges, bridge parts, bridge maintenance, etc., can solve problems such as ignoring bonding and cooperative deformation, and achieve the effect of shortening the curing time at room temperature and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

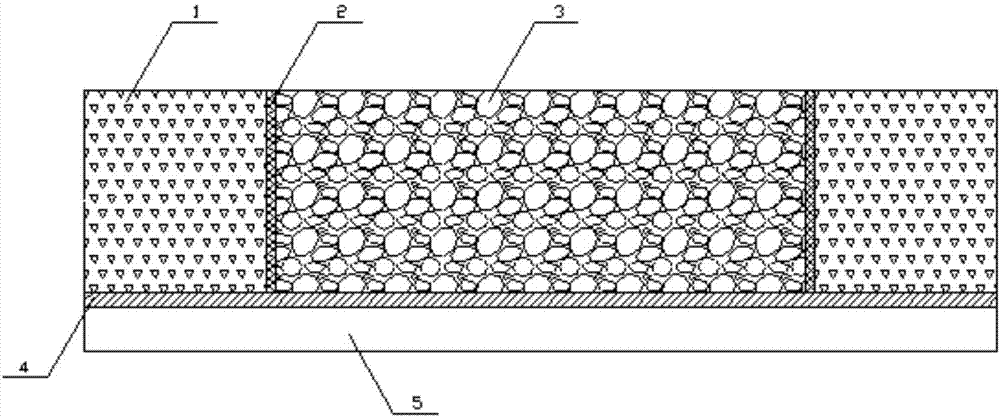

Image

Examples

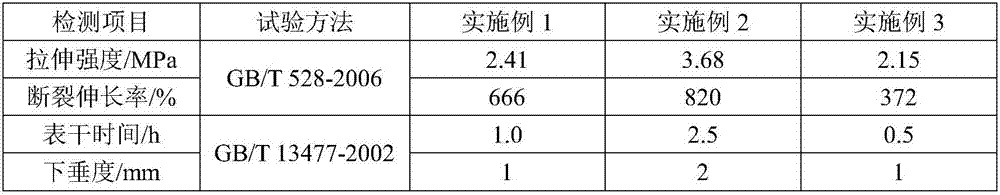

Embodiment 1

[0045] Prepare the wall-mounted high-elastic joint material for steel bridge deck pavement maintenance of the present invention:

[0046] (1) 100 parts of liquid polysulfide rubber G4 (Akzo Nobel Sulfur Chemicals (Taixing) Co., Ltd.), 40 parts of plasticizer dibutyl phthalate (Dongguan Ruiyu Chemical Co., Ltd.), 10 parts of plasticizer Adhesive resin epoxy resin (NPEL128, South Asia Epoxy Resin (Kunshan) Co., Ltd.), 1 part of coupling agent γ-aminopropyltriethoxysilane (Nanjing Shuguang Chemical Group Co., Ltd.), 200 parts of heavy calcium carbonate ( MJHF-1250, Suzhou Mingjiang Fine Chemical Co., Ltd.) and 5 parts of fumed silica (AEROSIL R974, Evonik Degussa) were sequentially put into a planetary mixer, stirred and mixed for 1 hour, and then ground three times with a three-roll mill to obtain Main agent A of wall-hanging high-elastic joint material.

[0047] (2) 40 parts of vulcanizing agent MnO 2 (β-MnO 2 , Xushui County Star Anticorrosion Material Factory), 50 parts of...

Embodiment 2

[0055] Prepare the wall-mounted high-elastic joint material for steel bridge deck pavement maintenance of the present invention:

[0056] (1) 100 parts of liquid polysulfide rubber G12 (Akzo Nobel Sulfur Chemicals (Taixing) Co., Ltd.), 50 parts of plasticizer butyl benzyl phthalate (Dongguan Ruiyu Chemical Co., Ltd.), 1 part of even Joint agent γ-(methacryloyloxy)propyltrimethoxysilane (Nanjing Shuguang Chemical Group Co., Ltd.), 230 parts of heavy calcium carbonate (MJHF-1250, Suzhou Mingjiang Fine Chemical Co., Ltd.) and 20 parts of light carbonic acid Calcium (MJ-HXQG, Suzhou Mingjiang Fine Chemical Co., Ltd.) was sequentially put into a planetary mixer, stirred and mixed for 1 hour, and then ground three times with a three-roll mill to obtain the main agent A of the wall-mounted high-elastic joint material.

[0057] (2) 100 parts of vulcanizing agent MnO 2 (γ-MnO 2 , Foshan Youhe Chemical Technology Co., Ltd.), 100 parts of plasticizer butyl benzyl phthalate (Dongguan Ru...

Embodiment 3

[0060] Prepare the wall-mounted high-elastic joint material for steel bridge deck pavement maintenance of the present invention:

[0061] (1) Mix 100 parts of liquid polysulfide rubber G1 (Akzo Nobel Sulfur Chemicals (Taixing) Co., Ltd.), 60 parts of plasticizer chlorinated paraffin (S52, Dongguan Ruiyu Chemical Co., Ltd.), 1 part of coupling agent γ-glycidyloxypropyltrimethoxysilane (Nanjing Shuguang Chemical Group Co., Ltd.), 200 parts of talcum powder (MJ-SL1250, Suzhou Mingjiang Fine Chemical Co., Ltd.) and 5 parts of nano calcium carbonate (MJ-NM60, Suzhou Mingjiang Fine Chemical Co., Ltd.) into a planetary mixer in turn, stirred and mixed for 1 hour, and then ground three times with a three-roll mill to obtain the main agent A of the wall-hanging high-elastic joint material.

[0062] (2) 40 parts of vulcanizing agent MnO 2 (α-MnO 2 , Xiangtan Weixin Manganese Products Co., Ltd.), 50 parts of plasticizer chlorinated paraffin (S52, Dongguan Ruiyu Chemical Co., Ltd.), 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com