Preparation method of NiAl/WC composite with high-temperature wear resistance

A composite material, tungsten carbide technology, applied in the field of material science, can solve the problems of complex steps, poor uniformity of binder phase distribution, and pores in composite materials, and achieves the effect of simple process, excellent high temperature wear resistance, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

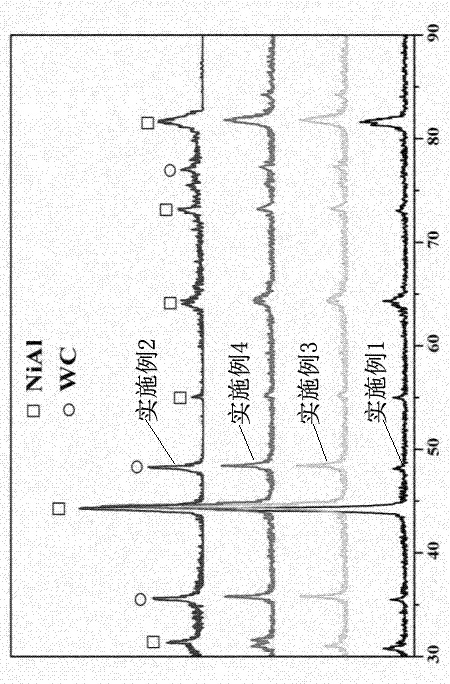

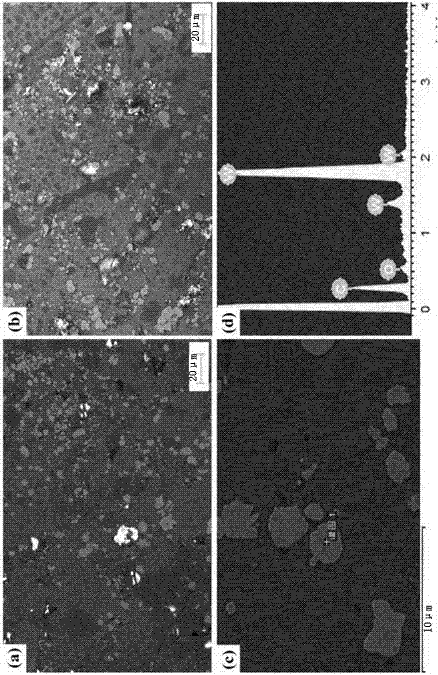

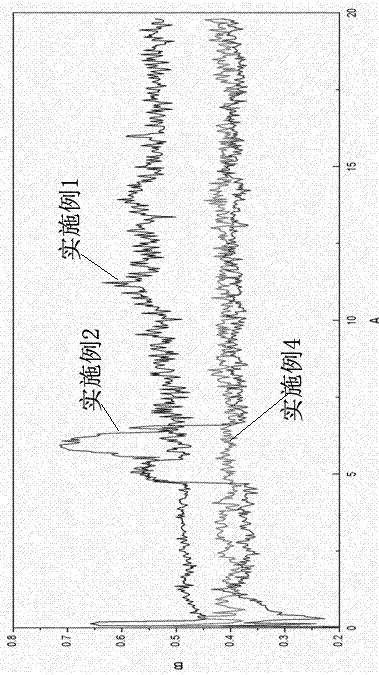

Embodiment 1

[0034] Embodiment 1 A kind of preparation method of nickel-aluminum-tungsten carbide composite material resistant to high temperature wear

[0035] (1) Ingredients

[0036] The specifications among the raw materials used in this process are as follows:

[0037] Ni powder: particle size is 200 mesh, purity 99.0%;

[0038] Al powder: particle size is 200 mesh, purity 99.5%;

[0039] WC powder: particle size is 200 mesh, purity 99.5%.

[0040] Mix Ni powder and Al powder according to the molar ratio of 1:1, then mix the Ni-Al mixed powder with WC powder, mill the mixed powder in a planetary ball mill for 2 hours, and the speed of ball milling is 300r / min to obtain a uniform mixture Ni-Al-WC mixed powder;

[0041] The mass percentage of WC powder in Ni-Al-WC mixed powder is 5%.

[0042] Compact

[0043] Apply a pressure of 200MPa to the Ni-Al-WC mixed powder mixed in step (1) to press into a compact; the compact is pressed into a cylindrical blank with a diameter of 40mm×30m...

Embodiment 2

[0046]Embodiment 2 A kind of preparation method of nickel-aluminum-tungsten carbide composite material resistant to high temperature wear

[0047] (1) Ingredients

[0048] The specifications among the raw materials used in this process are as follows:

[0049] Ni powder: particle size is 200 mesh, purity 99.0%;

[0050] Al powder: particle size is 200 mesh, purity 99.5%;

[0051] WC powder: particle size is 100 mesh, purity 99.5%.

[0052] Mix Ni powder and Al powder according to the molar ratio of 1:1, then mix the Ni-Al mixed powder with WC powder, mill the mixed powder in a planetary ball mill for 2 hours, and the speed of ball milling is 300r / min to obtain a uniform mixture Ni-Al-WC mixed powder;

[0053] The mass percentage of WC powder in the Ni-Al-WC mixed powder is 30%.

[0054] Compact

[0055] The Ni-Al-WC mixed powder mixed in step (1) is pressed into a compact under a pressure of 200MPa; the compact is pressed into a cylindrical blank with a diameter of 40mm×...

Embodiment 3

[0058] Embodiment 3 A kind of preparation method of nickel-aluminum-tungsten carbide composite material resistant to high temperature wear

[0059] (1) Ingredients

[0060] The specifications among the raw materials used in this process are as follows:

[0061] Ni powder: the particle size is 100 mesh, the purity is 95%;

[0062] Al powder: particle size is 100 mesh, purity 95%;

[0063] WC powder: the particle size is 100 mesh, and the purity is 95%.

[0064] Mix Ni powder and Al powder according to the molar ratio of 1:1, then mix the Ni-Al mixed powder with WC powder, mill the mixed powder in a planetary ball mill for 2 hours, and the speed of ball milling is 300r / min to obtain a uniform mixture Ni-Al-WC mixed powder;

[0065] The mass percentage of WC powder in the Ni-Al-WC mixed powder is 10%.

[0066] Compact

[0067] Apply a pressure of 350MPa to the Ni-Al-WC mixed powder mixed in step (1) to press into a compact; the compact is pressed into a cylindrical blank wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com