Inner layer active coating liquid and preparation method thereof

An active, liquid-coating technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low oxygen evolution potential, economic loss, and increase equipment cost, so as to reduce the oxygen evolution rate, improve the oxygen evolution potential, and improve the usage longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

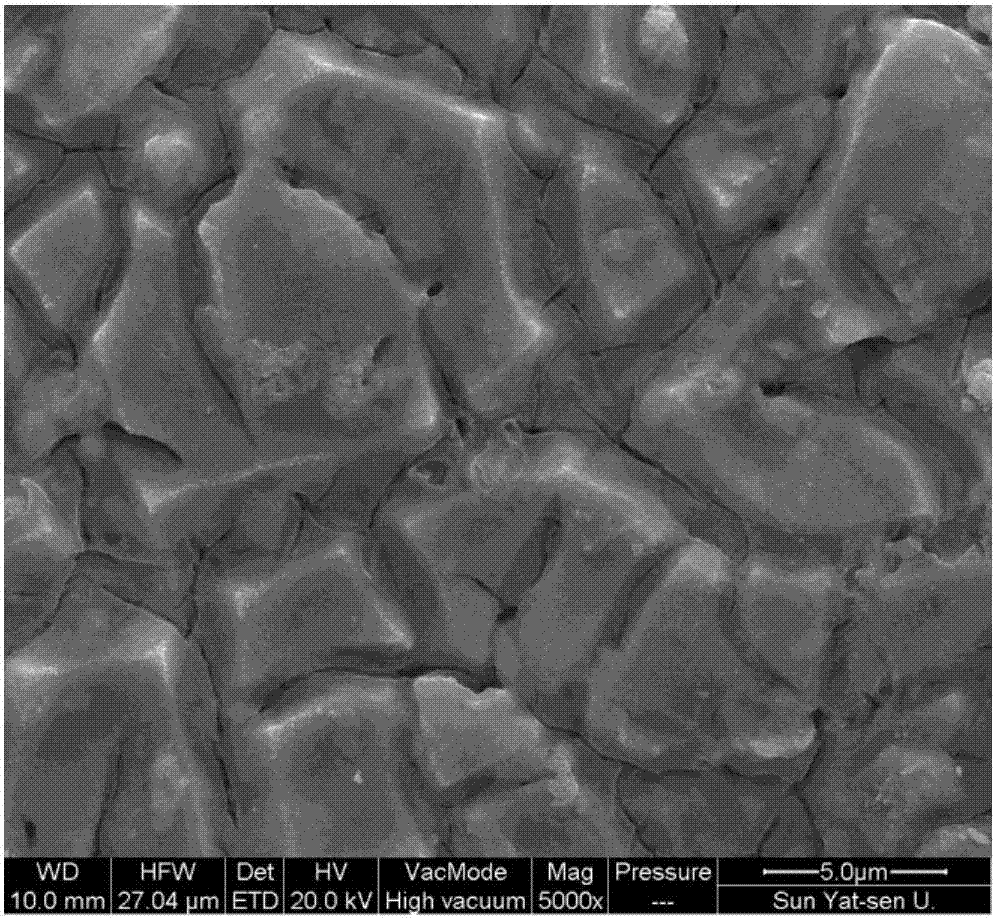

Image

Examples

preparation example Construction

[0029] A preparation method for inner layer active coating solution, comprising the following steps:

[0030] 1) Prepare the raw materials required for the solvent, solute and stabilizer, and prepare the solvent and solute according to the proportion for subsequent use;

[0031] 2) Add the solute to the solvent in turn, after fully dissolving, pour the stabilizer into it, and mix evenly.

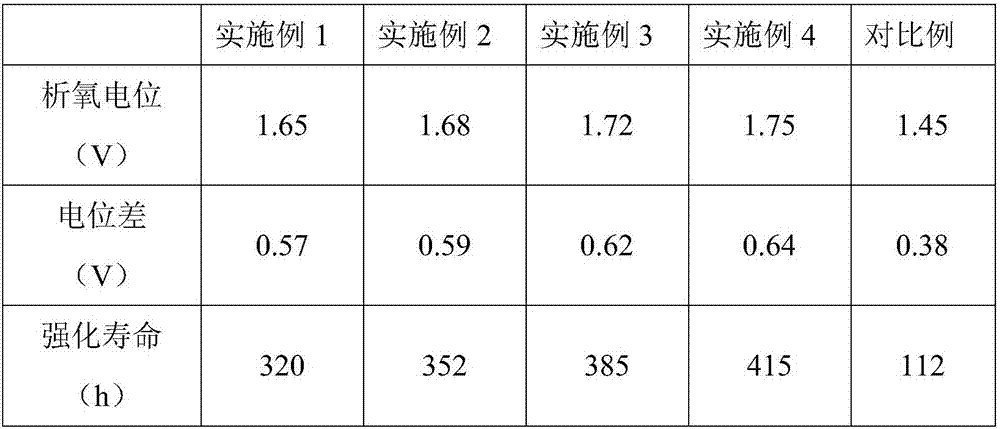

Embodiment 1

[0033] A kind of inner active coating liquid, comprises solvent, solute and stabilizer, and solvent is made up of n-butanol, isopropanol, and the mass ratio of n-butanol, isopropanol is 2:1 in the solvent, and stabilizer is concentrated hydrochloric acid, and solute It is composed of ruthenium trichloride, chloroiridic acid, tetrabutyl titanate and oxygen evolution inhibitor. The oxygen evolution inhibitor is composed of antimony pentachloride and cerium nitrate; the concentration of metal ions in the active coating solution of the inner layer is 0.32mol / L, the volume ratio of solvent to stabilizer is 10:1.

[0034] In the active coating solution of the inner layer, in terms of molar percentage of metal ions, the proportion of metal ions in the solution occupied by ruthenium ions is 17mol%, the proportion of metal ions in the solution occupied by iridium ions is 9mol%, and the proportion of metal ions in the solution occupied by titanium ions is The proportion of metal ions i...

Embodiment 2

[0036] A kind of inner active coating liquid, comprises solvent, solute and stabilizer, and solvent is made up of n-butanol, isopropanol, and the mass ratio of n-butanol, isopropanol is 2:1 in the solvent, and stabilizer is concentrated hydrochloric acid, and solute It is composed of ruthenium trichloride, chloroiridic acid, tetrabutyl titanate and oxygen evolution inhibitor. The oxygen evolution inhibitor is composed of chromium sulfate and cobalt carbonate; the metal ion concentration in the inner layer active coating solution is 0.34mol / L, The volume ratio of solvent to stabilizer is 10:1.

[0037] In the active coating solution of the inner layer, in terms of molar percentage of metal ions, the proportion of metal ions in the solution occupied by ruthenium ions is 19mol%, the proportion of metal ions in the solution occupied by iridium ions is 11mol%, and the proportion of metal ions in the solution occupied by titanium ions is The proportion of metal ions in the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com