Zinc oxidenanorod-carbon nanotubealcohol sensor and preparation method thereof

A technology of zinc oxide nanorods and carbon nanotubes, applied in the direction of material resistance, can solve the problems of poor response recovery characteristics and low sensitivity, and achieve the effects of high sensitivity, low cost, and high surface adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

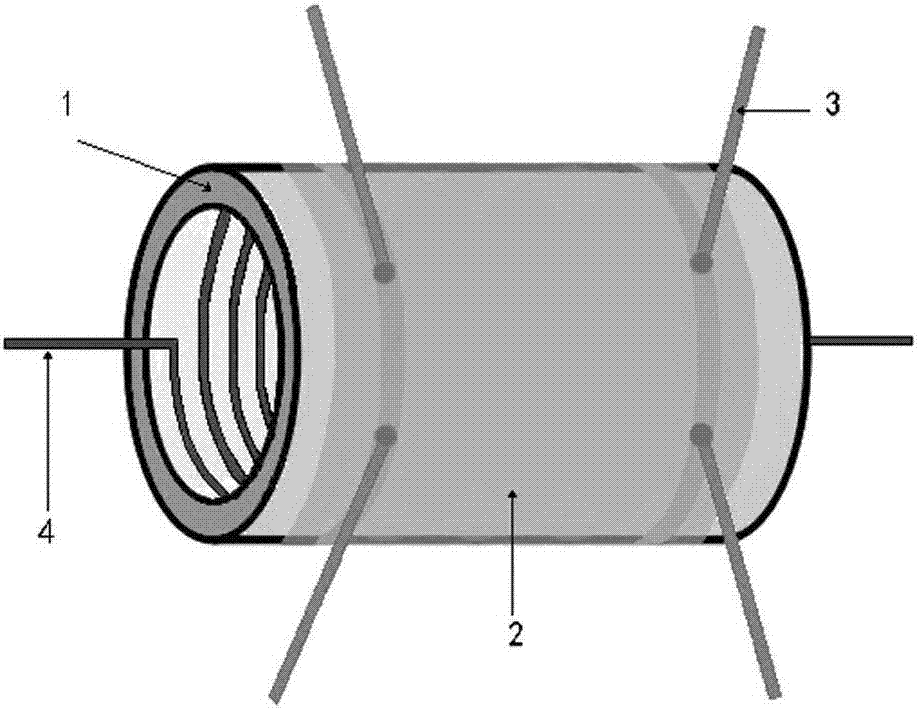

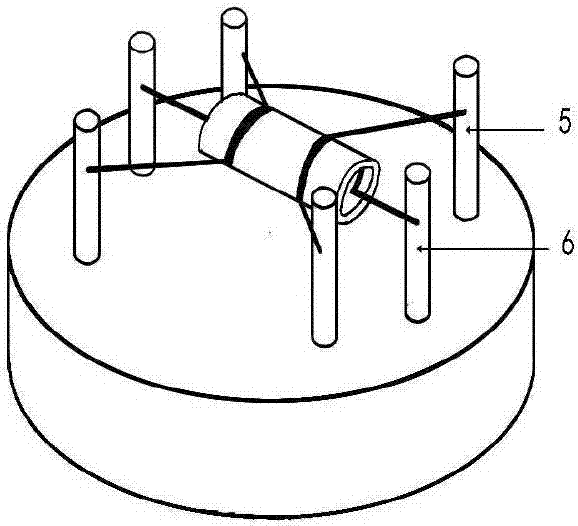

[0032] like figure 1 , figure 2 The shown zinc oxide nanorod-carbon nanotube ethanol sensor includes a ceramic tube 1 , a sensitive layer 2 on the ceramic tube, a test electrode 3 and a heating electrode 4 . A ceramic tube (about 4.1 mm in length, about 1.0 mm in inner diameter, and about 1.4 mm in outer diameter) is attached with gold electrodes at both ends, and 4 Pt wires are drawn from the gold electrodes as test electrodes; a helical nickel-chromium alloy wire runs through the ceramic tube, as a heating electrode; wherein, the sensitive layer is a zinc oxide nanorod-carbon nanotube composite material, covering the surface of the ceramic tube and between two gold electrodes.

[0033] The preparation process of zinc oxide nanorod-carbon nanotube ethanol sensor is as follows:

[0034] Preparation of zinc oxide nanorods: first, a mixed solution of zinc nitrate (0.05M), urotropine (0.05M), ammonia water (0.05M) and polyethyleneimine (2mM) was prepared with ultrapure water. ...

Embodiment 2

[0043]The structure and preparation steps of the zinc oxide nanorod-carbon nanotube ethanol sensor are as in Example 1, the mass fraction content of the carbon nanotubes in the zinc oxide nanorod-carbon nanotube composite material is reduced from 25% to 10%, and the obtained The sensitivity of the gas sensor to 50ppm concentration of ethanol was reduced from 16 to 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com