A system and method for coal desulfurization and recovery of elemental sulfur

A technology for recovering single and elemental sulfur, which is applied in the direction of sulfur preparation/purification, chemical instruments and methods, sulfur compounds, etc., and can solve the problem of not considering the microwave treatment process temperature, microwave leakage, failure to achieve continuous production, ignoring collection and sulfur Recycling and other issues, to achieve broad industrial application prospects, small footprint, and reduce the consumption of microwave energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

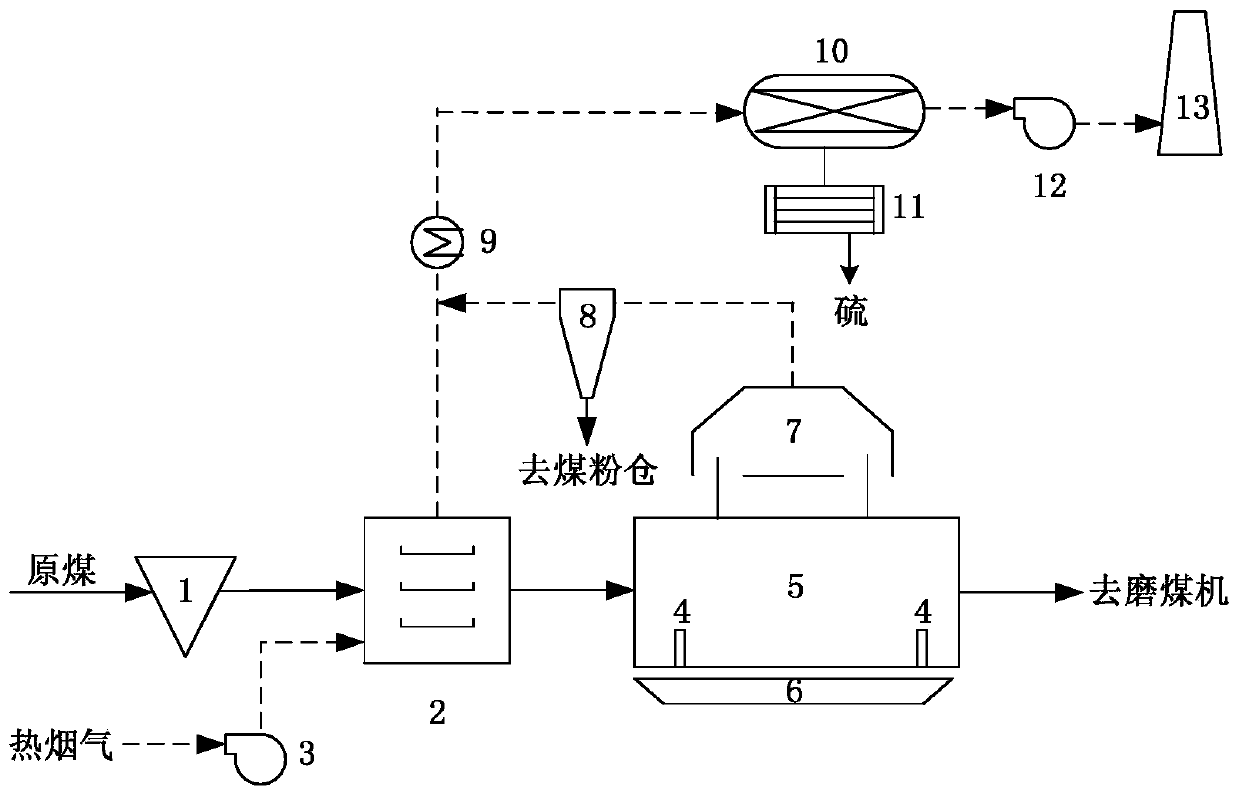

[0059] A system for desulfurizing high-sulfur coal and recovering elemental sulfur, such as figure 1 As shown, the system includes:

[0060] The raw coal crushing unit is used for crushing raw coal, including a crusher 1, and the crusher 1 is preferably a ring hammer crusher 1 and / or a hammer crusher 1;

[0061] Raw coal drying unit, used for drying raw coal, including dryer 2;

[0062] The microwave desulfurization unit is used for the microwave desulfurization of coal, including a microwave reactor 5, and the infrared temperature measuring probe 4, a humidity sensor and a pressure sensor connected to the control system are arranged in the microwave reactor 5; the microwave desulfurization unit also includes A microwave leakage suppression device 6, the microwave leakage suppression device 6 is made of graphite and / or alloy, and the microwave leakage suppression device 6 is arranged on the bottom and / or both sides of the microwave desulfurization unit;

[0063] The exhaust ...

Embodiment 2

[0073] Using the system described in Example 1, using the method for desulfurizing high-sulfur coal and producing elemental sulfur in Example 1, a high-sulfur coal desulfurization test was carried out. The details are as follows: In a 1000MW coal-fired power plant, the coal consumption is 360t / h, the sulfur content in the high-sulfur raw coal is 3.56%, and the moisture content is 6.11%. ℃ The boiler flue gas is introduced into the front end of the dryer, and the SO in the flue gas 2 The content is 2000mg / Nm 3 , O 2 The content is 6%, the flue gas flow rate is 15×10 4 N m 3 / h, the moisture content of raw coal after drying is reduced to 4.23%, the outlet flue gas temperature drops to 180°C, the raw coal after drying enters the conveyor belt, and the conveying capacity of the conveyor belt is 50t / h, and the raw coal enters the microwave reactor at 2540MHz , irradiation 3min in the microwave of power 300W, the sulfur content in the coal after desulfurization is reduced to 1.4...

Embodiment 3

[0076] Using the system described in Example 1, using the method for desulfurizing high-sulfur coal and producing elemental sulfur in Example 1, a high-sulfur coal desulfurization test was carried out. The details are as follows: In a 500MW coal-fired power plant, the coal consumption is 200t / h, the sulfur content in the high-sulfur raw coal is 6.24%, and the moisture content is 7.21%. ℃ The boiler flue gas is introduced into the front end of the dryer, and the SO in the flue gas 2 The content is 4000mg / Nm 3 , O 2 The content is 6%, the flue gas flow rate is 10×10 4 N m 3 / h, the moisture content of the raw coal after drying is reduced to 4.61%, the outlet flue gas temperature drops to 160°C, the dried raw coal enters the conveyor belt, and the conveying capacity of the conveyor belt is 30t / h, and the raw coal enters the microwave reactor at 2540MHz , the power of 500W microwave irradiation for 5 minutes, the sulfur content in the coal after desulfurization is reduced to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com