Preparation method of polysubstituted isoindolinone

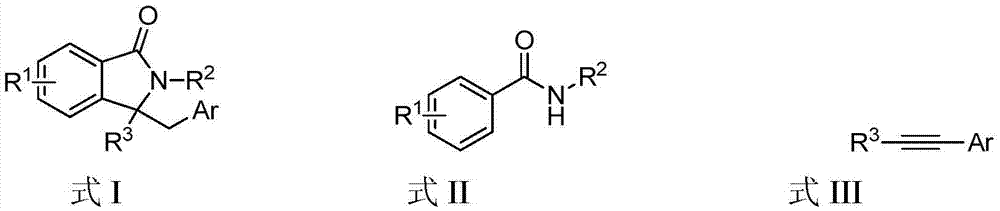

A technology of isoindolinone and multi-substitution, which is applied in the field of preparation of multi-substituted isoindolinone, can solve the problems of difficult to obtain synthetic raw materials and cumbersome steps, and achieve the application value of large drug synthesis, wide substrate range, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

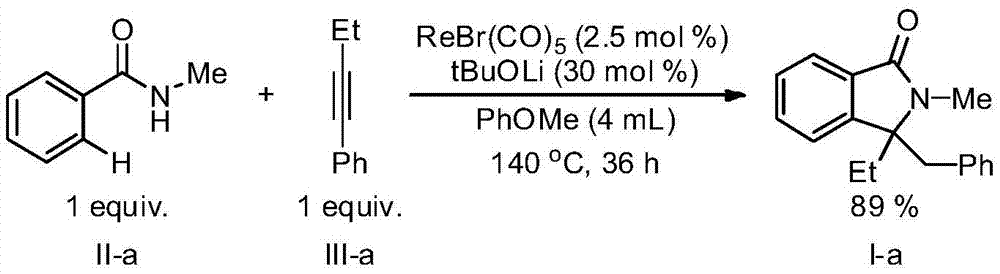

[0025] Embodiment 1, 3-ethyl-3-benzyl-N-methylisoindolinone (formula Ⅰ-a)

[0026]

[0027] into a 25mL Schlenk bottle under N 2 Under the protection of N-methylbenzamide (formula Ⅱ-a) (1mmol, 135.2mg), 1-phenyl-1-butyne (formula Ⅲ-a) (1mmol, 130mg), catalyst pentacarbonyl Rhenium bromide (0.025mmol, 10.2mg), base lithium tert-butoxide (0.3mmol, 24mg) and solvent anisole (4mL) were reacted at 140°C, and after 36h, saturated NaHCO 3 Solution (10 mL) was used to quench the reaction, and then extracted with dichloromethane, and the organic phases were combined, dried with anhydrous sodium sulfate, filtered, and spin-dried. After purification by column chromatography (eluent: petroleum ether: ethyl acetate = 5 / 1, v / v), 237 mg of the target product (Formula I-a) was obtained with a yield of 89%.

[0028] The target product is characterized as follows: 1 H NMR (300MHz, CDCl 3 ):7.63(d,J=7.5Hz,1H),7.51-7.53(m,1H),7.33(t,J=7.5Hz,1H),7.28(d,J=7.8Hz,1H),7.07-6.93 (m,3H),6.71-6.6...

Embodiment 2

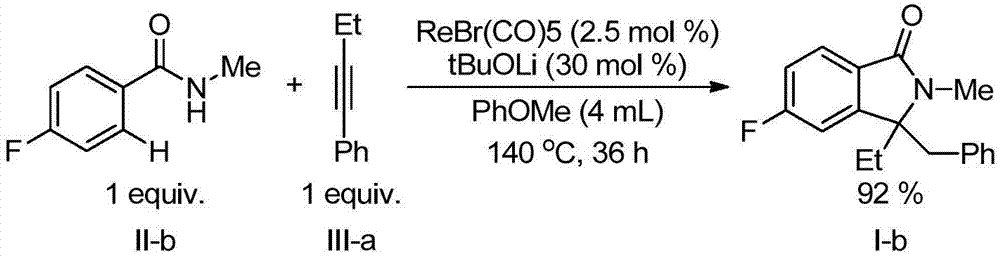

[0029] Example 2, 3-ethyl-3-benzyl-5-fluoro-N-methylisoindolinone (formula Ⅰ-b)

[0030]

[0031] into a 25mL Schlenk bottle under N 2 Under protection, 5-fluoro-N-methylbenzamide (formula Ⅱ-b) (1mmol, 153.1mg), 1-phenyl-1-butyne (formula Ⅲ-a) (1mmol, 130mg) were added successively , Catalyst rhenium pentacarbonyl bromide (0.025mmol, 10.2mg), base lithium tert-butoxide (0.3mmol, 24mg) and solvent anisole (4mL), react at 140 ℃, after 36h, use saturated NaHCO 3 Solution (10 mL) was used to quench the reaction, and then extracted with dichloromethane, and the organic phases were combined, dried with anhydrous sodium sulfate, filtered, and spin-dried. After purification by column chromatography (eluent: petroleum ether: ethyl acetate = 5 / 1, v / v), 261 mg of the target product (Formula I-a) was obtained with a yield of 92%.

[0032] The target product is characterized as follows: 1 H NMR (400MHz, CDCl 3 ):7.60(m,1H)7.06-7.00(m,4H),6.96(m,1H),6.74-6.71(m,2H),δ3.14(d,J=14Hz,1H)...

Embodiment 3

[0033] Example 3, 3-ethyl-3-benzyl-5-phenyl-N-methylisoindolinone (formula Ⅰ-c)

[0034]

[0035] into a 25mL Schlenk bottle under N 2 Under protection, 5-phenyl-N-methylbenzamide (formula Ⅱ-b) (1mmol, 211.2mg), 1-phenyl-1-butyne (formula Ⅲ-a) (1mmol, 130mg) were added successively ), the catalyst rhenium pentacarbonyl bromide (0.025mmol, 10.2mg), the base lithium tert-butoxide (0.3mmol, 24mg) and the solvent anisole (4mL), react at 150°C, and after 72h, use saturated NaHCO 3 Solution (10 mL) was used to quench the reaction, and then extracted with dichloromethane, and the organic phases were combined, dried with anhydrous sodium sulfate, filtered, and spin-dried. After purification by column chromatography (eluent: petroleum ether: ethyl acetate = 5 / 1, v / v), 292 mg of the target product (Formula I-c) was obtained with a yield of 85%.

[0036] The target product is characterized as follows: 1H NMR (300MHz, CDCl 3 ):7.71(d,J=7.8Hz,1H),7.60-7.55(m,3H),7.47(m 2H),7.40-7.36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com