Heating furnace visual combustion control system and method based on multi-parameter detection

A control system and control method technology, applied in the direction of controlling combustion, lighting and heating equipment, direct carbon dioxide emission reduction, etc., can solve the problems of difficult concentration of nitrogen oxides, large transient interference, and large pollution emissions, etc., to improve the device Operational efficiency, reduction of excess air content, and effect of reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

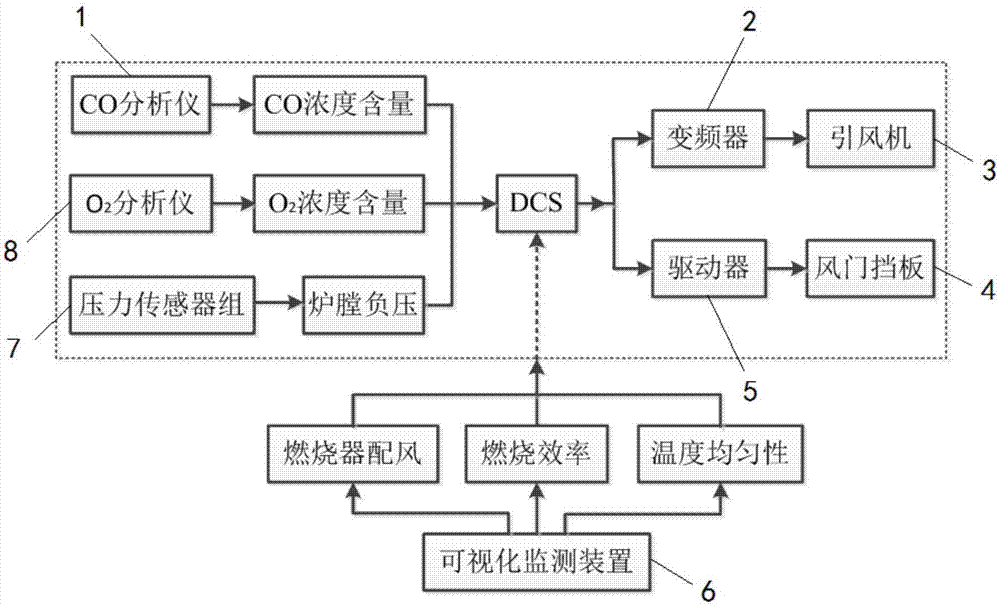

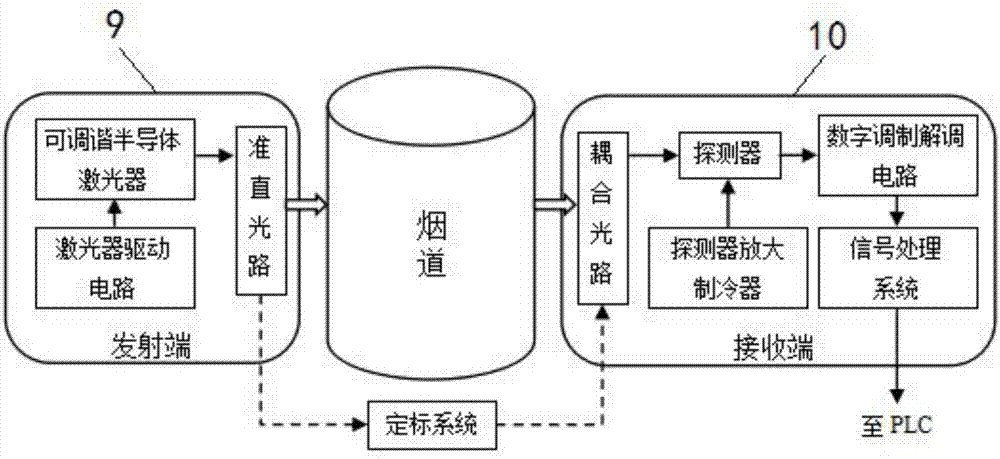

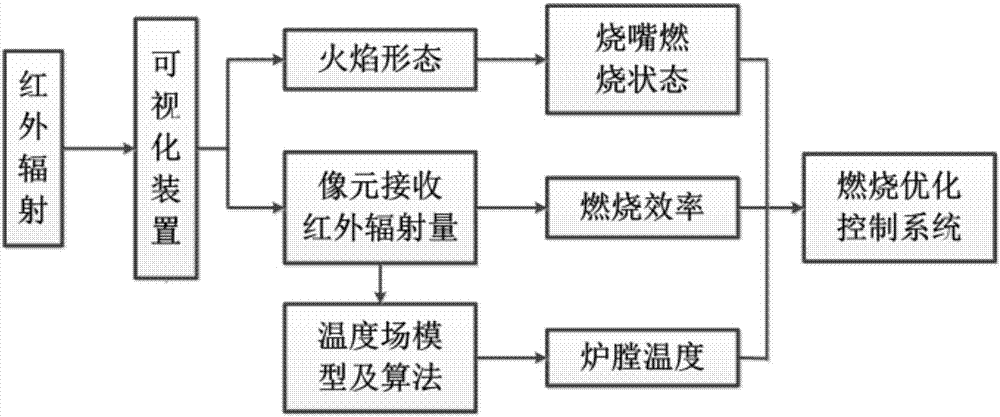

[0025] like figure 1 As shown, the visual combustion control system of the heating furnace based on multi-parameter detection of the present invention includes a CO analyzer 1 for on-line precise detection of CO content in flue gas, and an on-line detection of O in the furnace. 2 content of O 2 Analyzer 8, visual monitoring device 6, pressure sensor 7, frequency converter 2, induced draft fan 3, driver 5, damper baffle 4 and CO analyzer 1, O 2 Analyzer 8, pressure sensor 7 closed-loop control connected DCS control system, several pressure sensors 7 are installed in groups in the radiation section and convection section of the heating furnace, and the furnace pressure is determined by taking the median of the detection data of all individual pressure sensors 7 , the CO analyzer 1 and O used to detect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com