Skin care beautifying black Chinese wolfberry candy and preparation method thereof

A technology of wolfberry candy and black wolfberry, which is applied in the fields of food, health products and preparation, can solve the problems of only focusing on color, fragrance, etc., and achieve the effect of improving skin color, improving skin quality, and facilitating absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

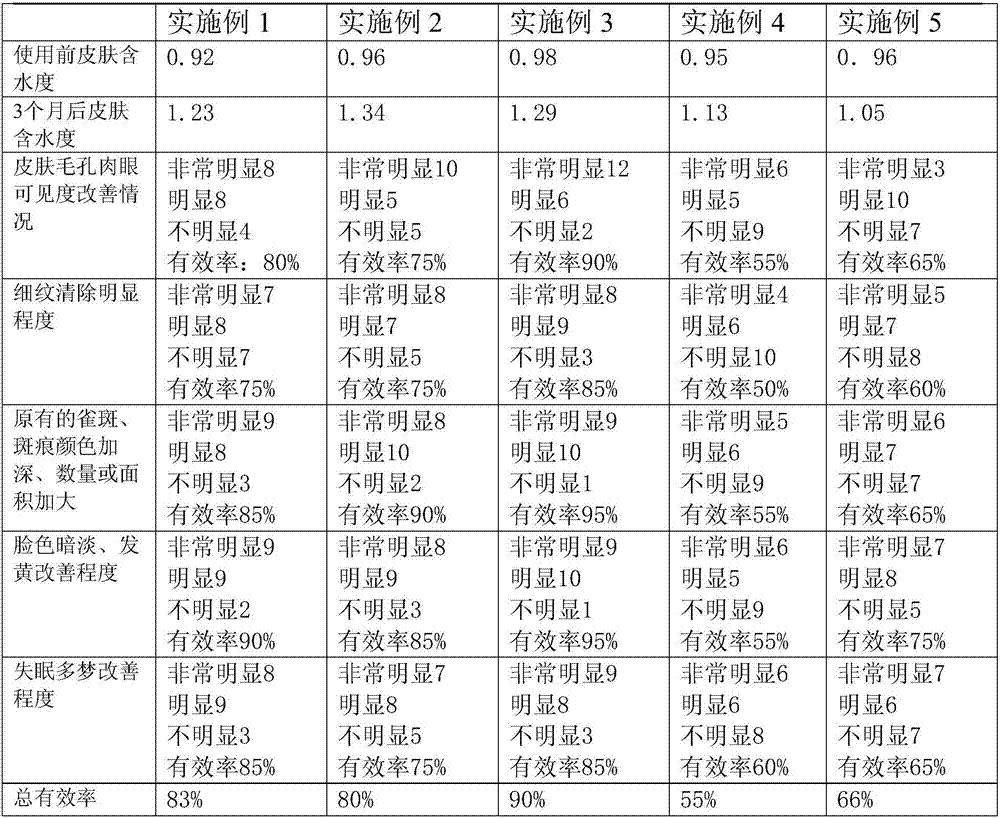

Examples

Embodiment 1

[0034] The dried fruit of black wolfberry is subjected to a temperature of -40 to -80°C, a freeze-drying pressure of 20Pa to 50Pa, freeze-drying for 10 to 15h, and then placed in a low-temperature ultrafine pulverizer for crushing at a temperature of -10°C to -20°C, and after 100 Mesh sieve to prepare black wolfberry powder; fry soybean germ, tartary buckwheat and coix seed and pulverize, remove the core of jujube and pulverize;

[0035] Weigh various raw materials, 55 parts of black wolfberry powder, 40 parts of tartary buckwheat powder, 16 parts of jujube powder, 16 parts of barley powder, 16 parts of soybean germ powder, 12 parts of honey powder, 20 parts of maltodextrin, microcrystalline cellulose 16 parts, 2 parts citric acid, 5 parts sucralose, 2 parts magnesium stearate

[0036] After weighing various raw materials according to the parts by weight, fully mix and homogenize, add 50% (m / v) edible alcohol, and pass through a 20-mesh sieve; dry the obtained semi-solid parti...

Embodiment 2

[0039] The dried fruit of black wolfberry is subjected to a temperature of -40 to -80°C, a freeze-drying pressure of 20Pa to 50Pa, freeze-drying for 10 to 15h, and then placed in a low-temperature ultrafine pulverizer for crushing at a temperature of -10°C to -20°C, and after 100 Mesh sieve to prepare black wolfberry powder; fry soybean germ, tartary buckwheat and coix seed and pulverize, remove the core of jujube and pulverize;

[0040] Weigh various raw materials, 45 parts of black wolfberry powder, 25 parts of tartary buckwheat powder, 25 parts of jujube powder, 25 parts of barley powder, 25 parts of soybean germ powder, 13 parts of honey powder, 30 parts of maltodextrin, microcrystalline cellulose 35 parts, 4 parts citric acid, 7 parts sucralose, 2 parts magnesium stearate

[0041] After weighing the various raw materials according to the weight parts, fully mix and homogenize, add 27% (m / v) edible alcohol, and pass through a 20-mesh sieve; dry the obtained semi-solid part...

Embodiment 3

[0044] The dried fruit of black wolfberry is subjected to a temperature of -40 to -80°C, a freeze-drying pressure of 20Pa to 50Pa, freeze-drying for 10 to 15h, and then placed in a low-temperature ultrafine pulverizer for crushing at a temperature of -10°C to -20°C, and after 100 Mesh sieve to prepare black wolfberry powder; fry soybean germ, tartary buckwheat and coix seed and pulverize, remove the core of jujube and pulverize;

[0045] Weigh various raw materials, 45 parts of black wolfberry powder, 30 parts of tartary buckwheat powder, 20 parts of jujube powder, 20 parts of barley powder, 20 parts of soybean germ powder, 8 parts of honey powder, 15 parts of maltodextrin, microcrystalline cellulose 20 parts, 2 parts citric acid, 6 parts sucralose, 3 parts magnesium stearate

[0046] After weighing the various raw materials according to the parts by weight, fully mix and homogenize, add 30% (m / v) edible alcohol, and pass through a 20-mesh sieve; dry the obtained semi-solid pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com