Bioactive glass composite biological tissue repairing material and preparation method thereof

A technology of bioactive glass and repair material, applied in the field of bioactive glass composite biological tissue repair material and its preparation, can solve the problems of poor mechanical properties, poor drug adhesion, etc., achieve low immunogenicity, slow degradation rate, increase ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

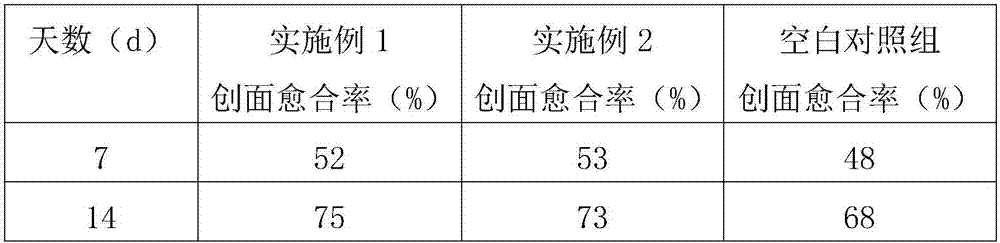

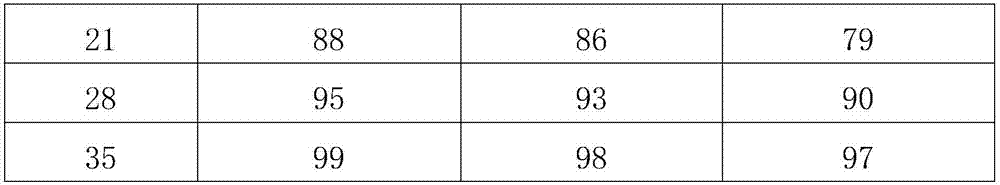

Examples

Embodiment 1

[0017] A bioactive glass composite biological tissue repair material, which is composed of the following raw materials in mass percentage: 35% of bioactive glass precursor solution, 35% of tetrahydrofuran, 10% of silk protein solution, 10% of silk protein nanofiber solution, nimesulide 3 %, Polyglycolide 3%, Green Tea Extract 2%, Sodium Hyaluronate 1%, Allantoin 1%.

[0018] The bioactive glass precursor solution is prepared by the following method: 4g P123 is dissolved in 60g ethanol, after fully stirring, 6.7g ethyl silicate, 0.73g triethyl phosphate, 1.4g Ca(NO 3 ) 2 4H 2 0. 1g of 0.5M hydrochloric acid solution; the mixed solution was stirred at room temperature for 24 hours and left to stand. When the solution was a viscous solution, the bioactive glass precursor solution was obtained.

[0019] The silk protein solution is prepared by the following method: heat 2L of deionized water to boiling, add 4g of sodium carbonate and 5g of silkworm raw silk, boil for 30min, clea...

Embodiment 2

[0024] A bioactive glass composite biological tissue repair material, which is composed of the following raw materials in mass percentage: 45% of bioactive glass precursor solution, 35% of tetrahydrofuran, 5% of silk protein solution, 5% of silk protein nanofiber solution, and 3% of nimesulide %, Polyglycolide 3%, Green Tea Extract 2%, Sodium Hyaluronate 1%, Allantoin 1%.

[0025] The bioactive glass precursor solution is prepared by the following method: 4g P123 is dissolved in 60g ethanol, after fully stirring, 6.7g ethyl silicate, 0.73g triethyl phosphate, 1.4g Ca(NO 3 ) 2 4H 2 0. 1g of 0.5M hydrochloric acid solution; the mixed solution was stirred at room temperature for 24 hours and left to stand. When the solution was a viscous solution, the bioactive glass precursor solution was obtained.

[0026] The silk protein solution is prepared by the following method: heat 2L of deionized water to boiling, add 4g of sodium carbonate and 5g of silkworm raw silk, boil for 30min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com