Manganese-doped supported palladium catalyst, preparation method thereof and application

A catalyst, palladium-supported technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as industrial application limitations, cumbersome preparation process, poor catalytic activity, etc. and stability, the carrier is cheap and easy to obtain, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

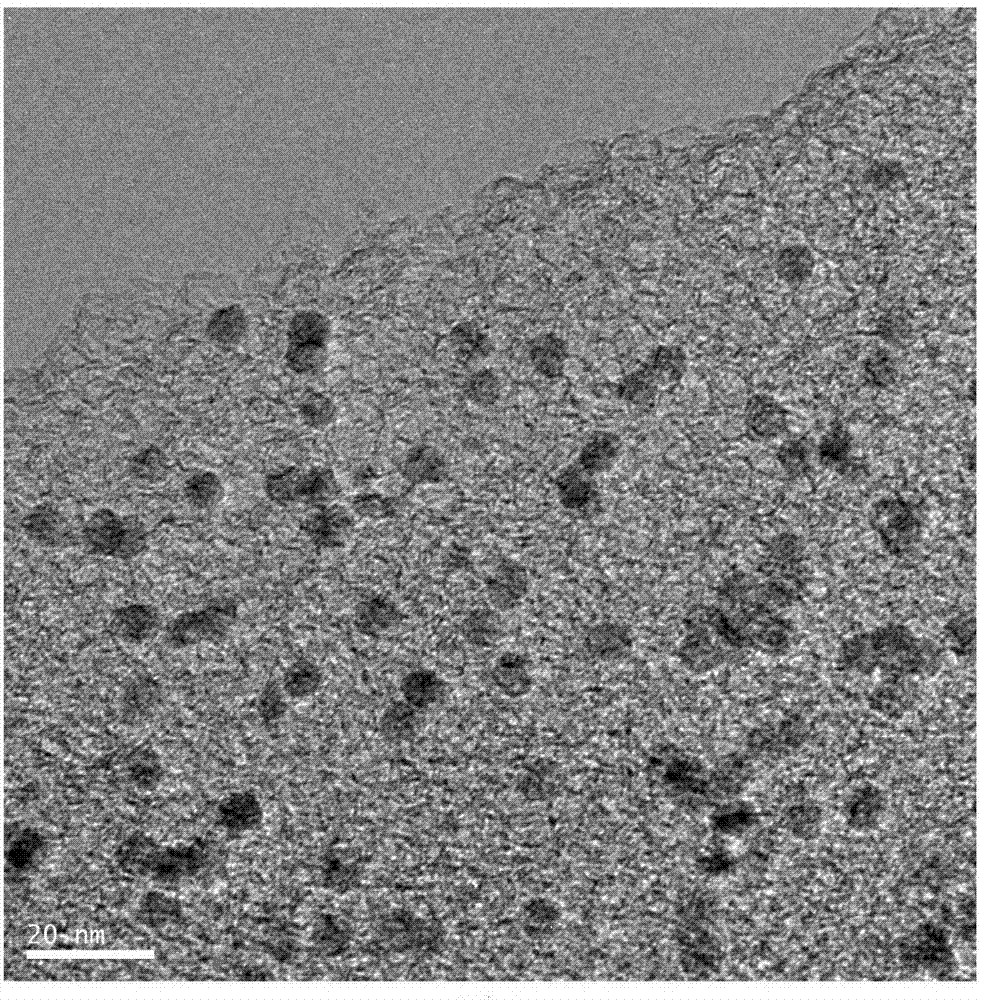

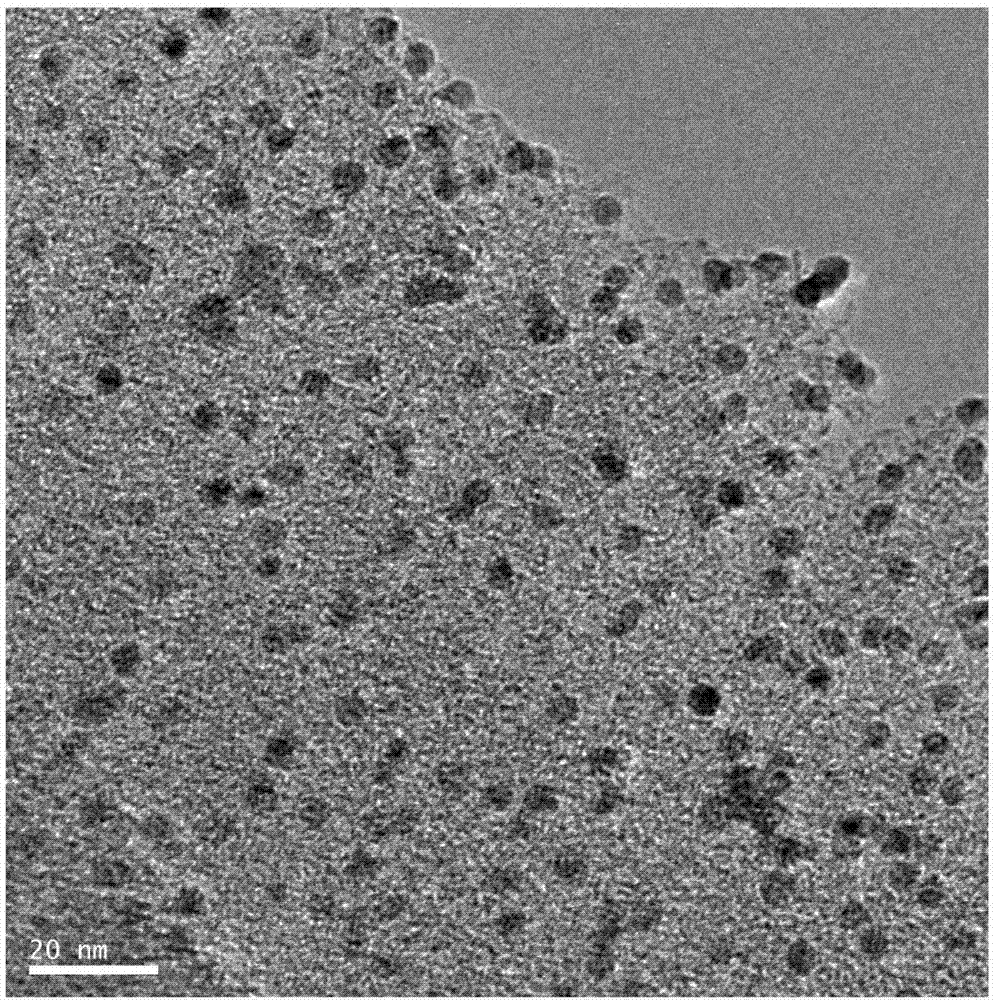

[0026] 0.083gPdCl 2 Added to 100mL propylene carbonate, at 3MPaH 2 Under the condition of environment and 20°C, the reaction was stirred for 2h to obtain a 0.5mg / mL Pd nano solution, and 1gAl 2 o 3 The carrier was added to 2mL of 0.5mg / mL Pd nano solution, impregnated and adsorbed, dried after standing for 10min, and then calcined at 350°C for 2h to obtain a Pd / Al with a loading capacity of 0.1%. 2 o 3 catalyst.

Embodiment 2

[0028] 0.167gPdCl 2 Added to 100mL propylene carbonate, at 3MPaH 2 Under the condition of environment and 20°C, the reaction was stirred for 2 hours to obtain a 1 mg / mL Pd nano solution, and 1 g Al 2 o 3 The carrier was added to 1 mL of 1 mg / mL Pd nano solution, impregnated and adsorbed, dried after standing for 10 min, and then calcined at 350 ° C for 2 h to obtain a Pd / Al with a loading capacity of 0.1%. 2 o 3 catalyst.

Embodiment 3

[0030] 0.417gPdCl 2 Added to 100mL propylene carbonate, at 3MPaH 2 Under the condition of environment and 20°C, the reaction was stirred for 2h to obtain a 2.5mg / mL Pd nano solution, and 1gAl 2 o 3 The carrier was added to 0.4mL2.5mg / mL Pd nano solution, impregnated and adsorbed, dried after standing for 10min, and then calcined at 350°C for 2h to obtain Pd / Al with a loading capacity of 0.1%. 2 o 3 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com