Wear-resistant antibacterial floor paint

A floor paint and nano calcium silicate technology, applied in the field of paint manufacturing industry, can solve the problems of poor wear resistance and hardness, easy yellowing of paint surface, poor gloss retention, etc., and achieve the effect of good temperature difference resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

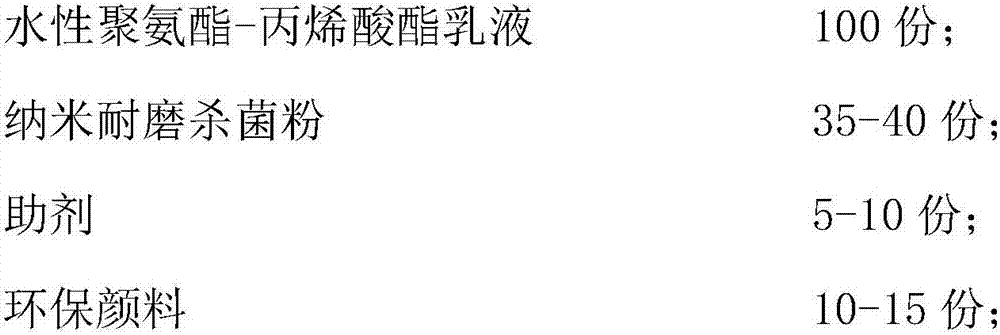

Embodiment 1

[0020] 1) Preparation of active nano-calcium silicate: Weigh 20g of nano-calcium silicate and place it in a ball mill, add 2% modifier silane coupling agent F-5, modify it at 600r / min ball mill speed for 40min to obtain The powder is the active nano-calcium silicate.

[0021] 2) Preparation of wear-resistant and bactericidal floor paint: Take nano-silver-loaded silica, nano-activated carbon and the above-mentioned activated nano-calcium silicate with a mass ratio of 1:2:1.5, and mix and stir for 10 minutes in a high-speed mixing mixer to obtain nano-resistant Grinding bactericidal powder, mixing 35 parts of nanometer wear-resistant bactericidal powder with 2 parts of wetting agent, 2 parts of dispersant, 0.4 part of defoamer, 0.8 part of antifungal agent, 0.7 part of antiaging agent, and 2.8 parts of film forming agent Mix and stir 5 parts of additives in a high-speed dispersion mixing mixer for 15 minutes to obtain a mixed nano-wear-resistant bactericidal powder, and then add...

Embodiment 2

[0023] The preparation method of this embodiment is the same as that of Example 1, except that 40 parts of nanometer wear-resistant bactericidal powder and 10 parts of auxiliary agent are used.

Embodiment 3

[0025] The preparation method of this example is the same as that of Example 2, except that the water-based polyurethane-acrylate emulsion has a solid content of 40%, 20 parts of other fillers, and a particle size of 300 mesh.

[0026] The performance test of the floor paint prepared by the embodiment is as follows: the conventional performance adhesion of the floor paint is according to GB / T9286-1998, and the hardness is according to GB / T6739-2006. According to the "Disinfection Technical Specification" released in 2016 by the Ministry of Health And according to the "GB15982-2012 Hospital Disinfection Hygienic Standard" sampling results.

[0027]

[0028]

[0029] Considering comprehensively, the performance of embodiment 2 is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com