Graphene formaldehyde removal and thermal insulation wallpaper and wall cloth and preparation method

A graphene and wallpaper technology, applied in ink, papermaking, paper coating, etc., can solve the problems of formaldehyde pollution, large temperature difference, etc., and achieve the effect of increasing interaction, excellent thermal insulation performance, improving decomposition efficiency and purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

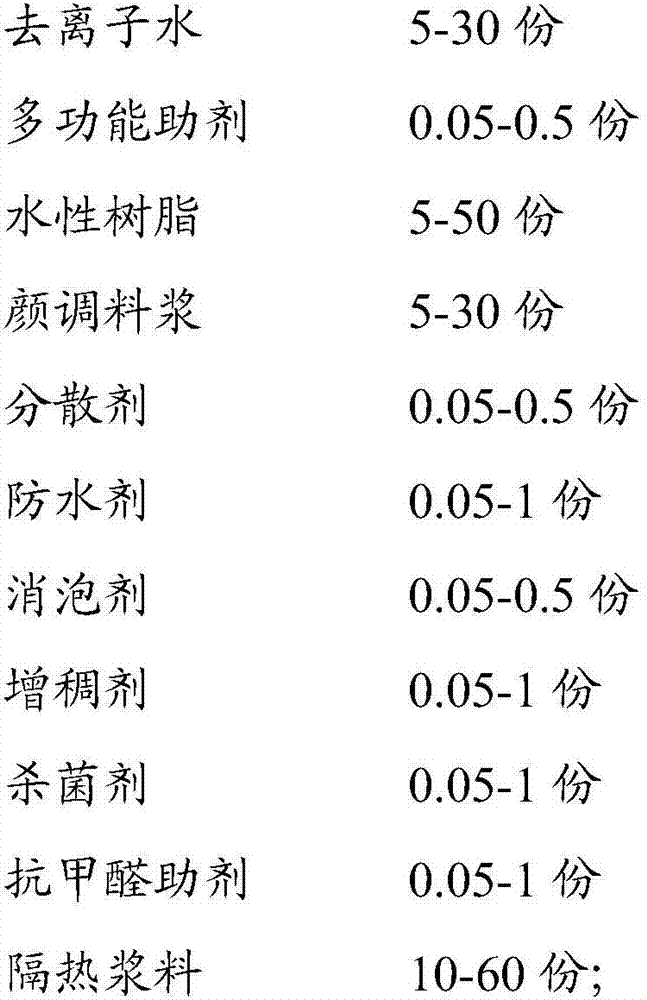

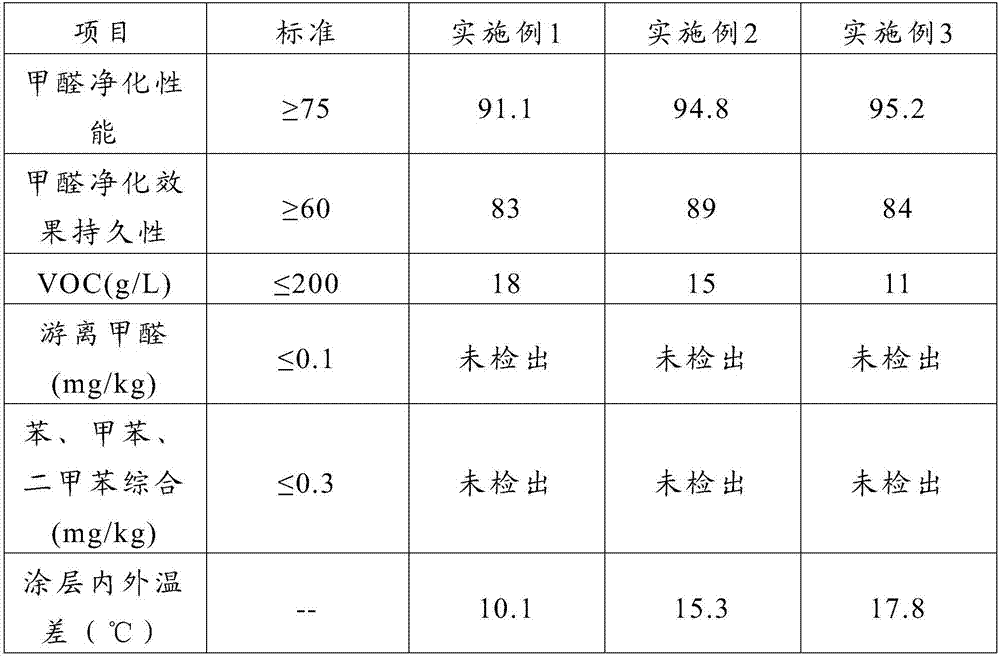

[0027] (1) 5 parts of deionized water, 0.3 parts of multifunctional amine additive (AMP-95), 42.5 parts of water-based acrylic resin, 30 parts of pigment and filler slurry, dispersant (the quality of sodium hexametaphosphate and sodium lauryl sulfate) Ratio 1:2) 0.5 part, waterproofing agent 0.5 part, non-ionic alkyl copolymer defoamer (CHE COAT DF9000) 0.3 part, associative alkali swelling thickener (CHE COATVT-183) 0.1 part, polyurethane 0.1 part of thickener (CHE COAT VT-903), 0.5 part of fungicide (Clariant HF-1), 0.2 part of anti-formaldehyde additive (ratio of nano-TiO2 and graphene is 2:8), 20 parts of thermal insulation slurry Mixed to obtain aldehyde-removing heat-insulating paint wallpaper coating;

[0028] (2) Heat the paper at an initial temperature of 20°C for 3 minutes at a heating rate of 2°C / min to perform the first preheating treatment; then raise the temperature at a heating rate of 7°C / min for 2 minutes to perform the second preheating treatment;

[0029] (...

Embodiment 2

[0031] (1) 3 parts of deionized water, 0.2 parts of multifunctional amine additive (AMP-95), 49.5 parts of water-based acrylic resin, 5 parts of pigment and filler paste, dispersant (the quality of sodium hexametaphosphate and sodium lauryl sulfate Ratio 1:2) 0.3 parts, waterproofing agent 0.8 parts, non-ionic alkyl copolymer defoamer (CHE COAT DF9000) 0.2 parts, associative alkali swelling thickener (CHE COATVT-183) 0.1 parts, polyurethane 0.2 parts of thickener (CHE COAT VT-903), 0.5 parts of fungicide (Clariant HF-1), 0.2 parts of anti-formaldehyde additive (nano-TiO2 and graphene ratio of 5:5), 40 parts of thermal insulation slurry Mixed to obtain aldehyde-removing heat-insulating paint wallpaper coating;

[0032] (2) Raise the temperature of the non-woven fabric at a starting temperature of 25°C for 2 minutes at a heating rate of 3°C / min for the first preheating treatment; then raise the temperature for 3 minutes at a heating rate of 10°C / min for the second preheating de...

Embodiment 3

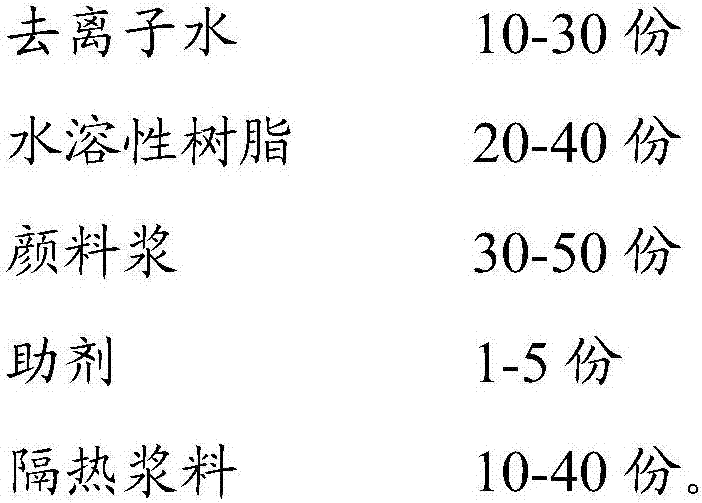

[0035] (1) 5.5 parts of deionized water, 30 parts of water-based acrylic resin, 32 parts of phthalocyanine blue pigment slurry, 0.5 part of defoamer (CHECOAT DF9000), 0.5 part of polyurethane thickener (CHE COATVT-903), water-soluble anion 1 part of fluorocarbon, 0.5 part of anti-formaldehyde additive (nano-TiO2 and graphene ratio of 8:2), and 30 parts of heat-insulating slurry are mixed to prepare water-based environmentally friendly ink heat-insulating wallpaper coating;

[0036] (2) The fabric is heated at a starting temperature of 25° C. for 3 minutes at a heating rate of 1° C. / min to perform the first preheating treatment; then the temperature is raised at a heating rate of 8° C. / min for 5 minutes to perform the second preheating treatment;

[0037] (3) Coat the heat-insulating wallpaper coating of water-based environmental protection ink on the preheated fabric, heat at 125°C for 40 minutes, and emboss to make graphene aldehyde-removing heat-insulating wall covering 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com