Multi-spectrum light emitting diode structure

A light-emitting diode and multi-spectral technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large number of chips, loss of conversion efficiency, difficulty in coordinating LED luminous efficiency, color rendering index, color temperature and luminous efficiency, etc., and achieve chip The number of particles is large, the number of chips is reduced, and the spectrum is flexible and changeable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

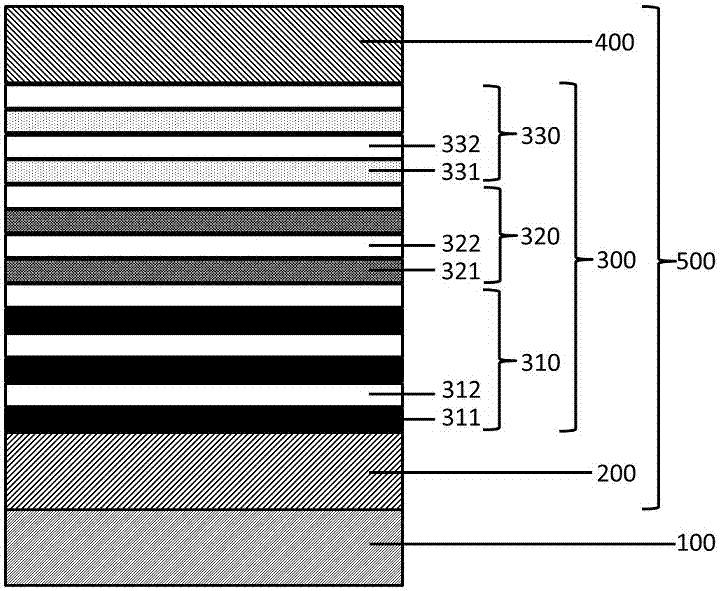

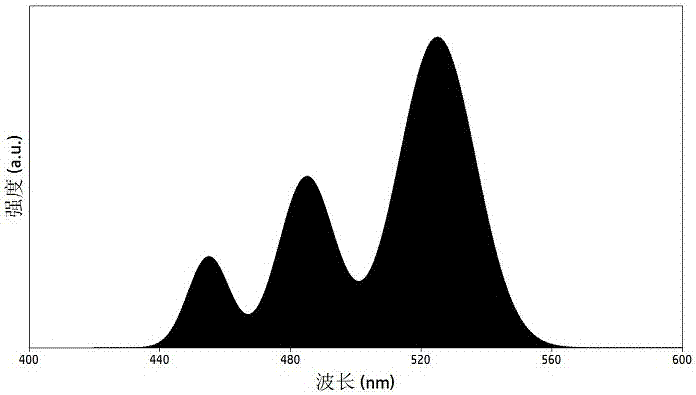

[0018] The substrate 100 adopts a silicon (Si) substrate, and the semiconductor stack 500 adopts In x Ga y Al 1-x-y N material system, n-type semiconductor layer 200 is doped with Si concentration 2×10 18 ─5×10 18 cm -3 GaN; p semiconductor layer 400 is doped with Mg concentration 1×10 20 cm -3 GaN; multi-spectral light-emitting multi-quantum well layer 300 is composed of three groups of multi-quantum well light-emitting units 310, 320 and 330 stacked and arranged sequentially from bottom to top, wherein multi-quantum well light-emitting unit 310 is composed of five periods of quantum wells 311 and quantum barriers 312. The quantum well 311 emits blue light with a wavelength of 450-460nm. The multi-quantum well light-emitting unit 320 is composed of two periods of quantum wells 321 and quantum barriers 322. The quantum well 321 emits blue light with a wavelength of 480-490nm. Well light-emitting unit 330 is made up of quantum well 331 and quantum barrier 332 of 1 period...

Embodiment 2

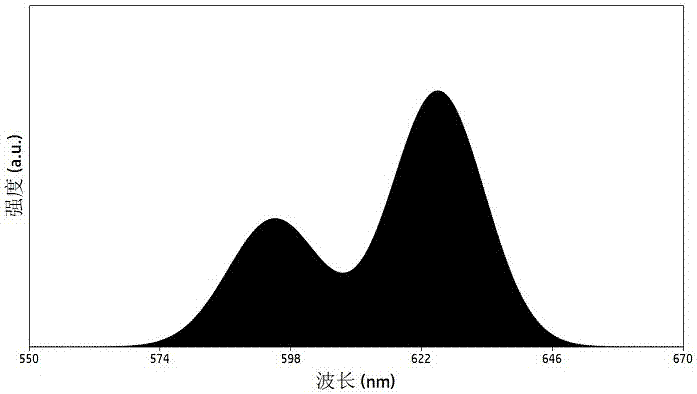

[0020] The substrate 100 is a gallium arsenide (GaAs) substrate, and the semiconductor stack 500 is In x Ga y Al 1-x-y P material system; n-type semiconductor layer 200 is n-type indium gallium aluminum phosphorus (Al x Ga y I n1-x-y P, 1≥x≥0, 1≥y≥0); the p semiconductor layer 400 is p-type indium gallium aluminum phosphorus (Al x Ga y I n1-x-y P, 1≥x≥0, 1≥y≥0); the multi-spectral light-emitting multi-quantum well layer 300 is composed of two sets of multi-quantum well light-emitting units 310 and 320 stacked in sequence, and the multi-quantum well light-emitting unit 310 consists of five periods The quantum well 311 and the quantum barrier 312 are composed of the quantum well 311, and the quantum well 311 emits orange light with a wavelength of 590-600nm. -630nm red light; the luminescent spectrum of the multi-spectral light-emitting diode structure in the present embodiment is the spectrum of red and orange two-color light synthesis, and its spectrum can be adjusted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com