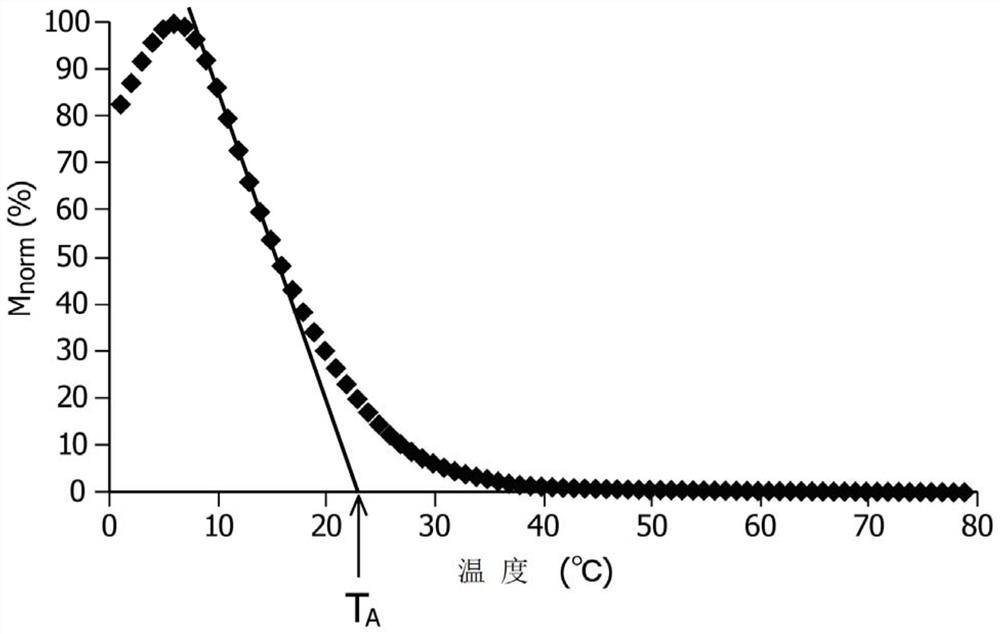

Solid preparation containing alkyl cellulose and production method thereof

A solid preparation, methyl cellulose technology, applied in the field of solid preparations, to achieve high tablet hardness, high formability, and reduced production of fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Wood pulp having an intrinsic viscosity of 1,400 ml / g was pulverized using a pulverizer to obtain cellulose pulp powder. An amount of cellulose pulp powder corresponding to 6.0 kg of cellulose was placed in an internally stirred pressure-resistant reactor with a jacket. The reactor was evacuated and purged with nitrogen to completely remove oxygen from the reactor. Then, the internal temperature of the reactor was adjusted to 55° C. with its internal stirring, and 49% by weight aqueous sodium hydroxide solution was used as the first alkali metal hydroxide solution at 12.04 [mol / mol hr] at an addition rate in such an amount that the molar ratio of the first sodium hydroxide to the cellulose (first sodium hydroxide / cellulose) becomes 3.01 to obtain alkaline cellulose.

[0107] Then 2.4 kg of dimethyl ether was added to the reactor, and the internal temperature of the reactor was controlled so as to maintain the internal temperature at 60°C. After the addition of dimethy...

Embodiment 2

[0133] The desired pulverized low-degree-of-polymerization methylcellulose was obtained in the same manner as in Example 1, except that the low-polymerization-degree methylcellulose obtained in Example 1 was used in an air flow impact mill Jet Mill ( Labo JetMill, manufactured by Nippon Kinetic Manufacturing Co., Ltd.) was pulverized under the following conditions: 0.35 MPa grinding pressure, 20 mm classification zone clearance and large louver size. Powder physical properties of pulverized low-polymerization degree methylcellulose, and tablet physical properties of tablets produced therefrom by dry direct compression in the same manner as in Example 1 are shown in Table 1.

Embodiment 3

[0135] The desired pulverized low degree of polymerization methylcellulose was obtained in the same manner as in Example 2, except that a grinding pressure of 0.45 MPa, a clearance of the classification zone of 35 mm and a large skylight size were used as the air flow impact mill JetMill crushing conditions. Powder physical properties of pulverized low-polymerization degree methylcellulose, and tablet physical properties of tablets produced therefrom by dry direct compression in the same manner as in Example 1 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com