An iron-based sub-nanometer alloy with good production processability and preparation method thereof

A nano-alloy and production process technology, applied in the field of new sub-nano soft magnetic alloy materials, can solve the problems of uneven structure, harsh preparation conditions, coarse α-Fe crystal grains, etc., and achieves short heat treatment time and stable heat treatment process. , the effect of high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

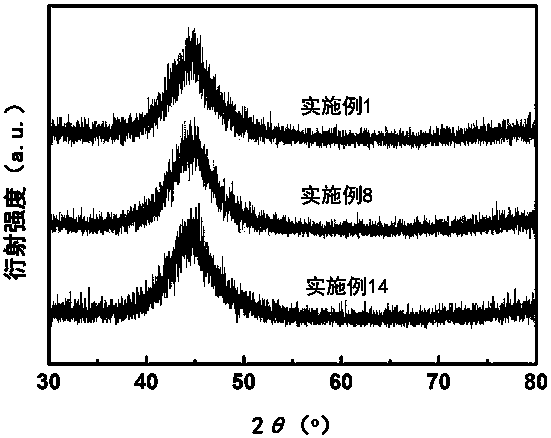

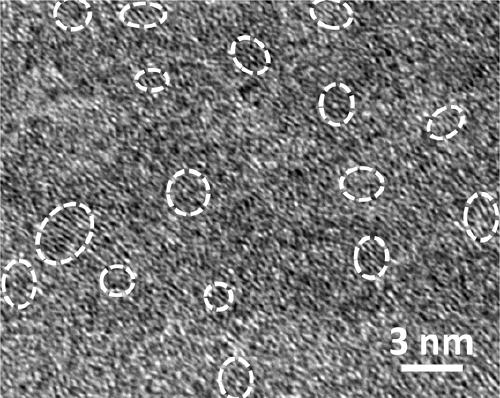

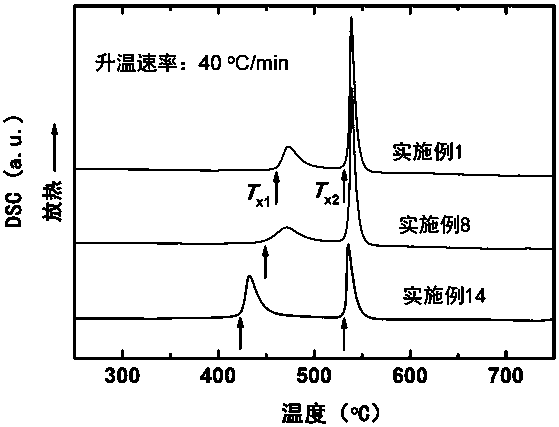

[0045] Embodiment 1: In this embodiment, the chemical formula of the iron-based sub-nanometer alloy is Fe 77 Si 4 B 16.5 Cu 1.2 Zr 1.3 .

[0046] The preparation of the iron-based sub-nanometer alloy and its subsequent heat treatment method are as follows:

[0047] (1) Fe, Si, Cu, Zr and Fe-B alloy raw materials with a purity greater than 99% are batched according to the chemical formula of the alloy composition;

[0048] (2) Place the raw materials prepared in step (1) in a high-frequency induction melting furnace, and vacuumize to 1×10 -2 Below Pa, then fill in an appropriate amount of high-purity argon, melt the prepared raw materials in an argon atmosphere, and keep warm for 30 minutes after all the raw materials are melted, so that the alloy raw materials can be melted evenly, and then pour the molten steel into the casting copper mold , cooling to obtain a master alloy ingot;

[0049] (3) Break the master alloy ingot, put an appropriate amount into a quartz tube w...

Embodiment 2-7

[0057] The specific composition of each alloy is shown in Table 1.

[0058] The preparation, heat treatment, structure and performance testing process of the sub-nanometer alloy strip in this series of embodiments, except that the smelting temperature, the speed of the strip-making copper roll and the heat treatment process parameters are different from those in Example 1, the remaining methods and process parameters are the same as those in Example 1. The same as that of embodiment 1.

[0059] The main magnetic performance indicators of the alloy strips in this series of examples before and after heat treatment are shown in Table 1. As can be seen from the table, after heat treatment, the B of all the example alloys S significantly increased, and H c Significantly decreased, the comprehensive soft magnetic performance has been significantly improved.

Embodiment 8

[0060] Embodiment 8: In this embodiment, the chemical formula of the iron-based sub-nanometer alloy is Fe 78 Si 4 B 16 Cu 1.3 Ti 0.7 .

[0061] The preparation of the iron-based sub-nanometer alloy and its subsequent heat treatment method are as follows:

[0062](1) Fe, Si, Cu, Ti and Fe-B alloy raw materials with a purity greater than 99% are batched according to the chemical formula of the alloy composition;

[0063] (2) Place the raw materials prepared in step (1) in a high-frequency induction melting furnace, and vacuumize to 1×10 -2 Below Pa, then fill in an appropriate amount of high-purity argon, melt the prepared raw materials in an argon atmosphere, and keep warm for 30 minutes after all the raw materials are melted, so that the alloy raw materials can be melted evenly, and then pour the molten steel into the casting copper mold , cooling to obtain a master alloy ingot;

[0064] (3) Break the master alloy ingot, put an appropriate amount into a quartz tube with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com