Fresh meat lecithin and preparation method thereof

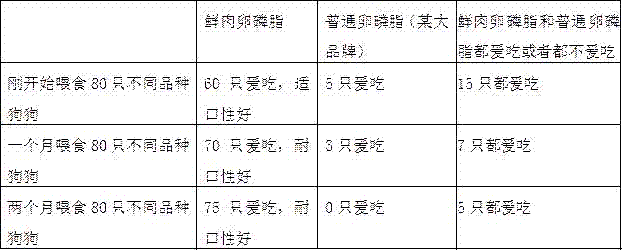

A technology of lecithin and concentrated lecithin, which is applied in animal feed, additional food elements, animal feed, etc., can solve the problems of poor palatability and large nutritional loss of cats and dogs, and achieve good palatability, less loss of nutritional components, and a preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A. After mixing 62 parts of concentrated lecithin powder, 18 parts of fresh meat, 7 parts of fish oil, 1.5 parts of multivitamins, 10 parts of wheat germ, and 1.5 parts of mixed tocopherols, enter the mixer of the molding machine and mix evenly;

[0017] B. Mold the mixed raw material mixture in a molding machine, and the material temperature is 33°C;

[0018] C. Dry the formed semi-finished product in a drying room at a drying temperature of 55°C for 20 hours, drying to a moisture content of 16%, and packaging to obtain fresh meat lecithin.

Embodiment 2

[0020] A. After mixing 58 parts of concentrated lecithin powder, 22 parts of fresh meat, 9 parts of fish oil, 1.5 parts of multivitamins, 9 parts of wheat germ, and 0.5 parts of mixed tocopherols, enter the mixer of the molding machine and mix evenly;

[0021] B. The mixed raw material mixture is molded in a molding machine, and the material temperature is 34°C;

[0022] C. Dry the formed semi-finished product in a drying room at a drying temperature of 55°C for 20 hours, drying to a moisture content of 16%, and packaging to obtain fresh meat lecithin.

Embodiment 3

[0024] A. After mixing 60 parts of concentrated lecithin powder, 20 parts of fresh meat, 8 parts of fish oil, 1 part of multivitamin, 10 parts of wheat germ, and 1 part of mixed tocopherol, enter the mixer of the molding machine and mix evenly;

[0025] B. The mixed raw material mixture is molded in a molding machine, and the material temperature is 35°C;

[0026] C. Dry the formed semi-finished product in a drying room at a drying temperature of 55°C for 20 hours, drying to a moisture content of 16%, and packaging to obtain fresh meat lecithin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com