C/Fe-FeVO4 composite photocatalyst as well as preparation method and application thereof

A technology of composite light and catalyst, used in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve problems such as unsatisfactory visible light utilization rate and achieve good visible light response , stable performance, improve the effect of visible light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

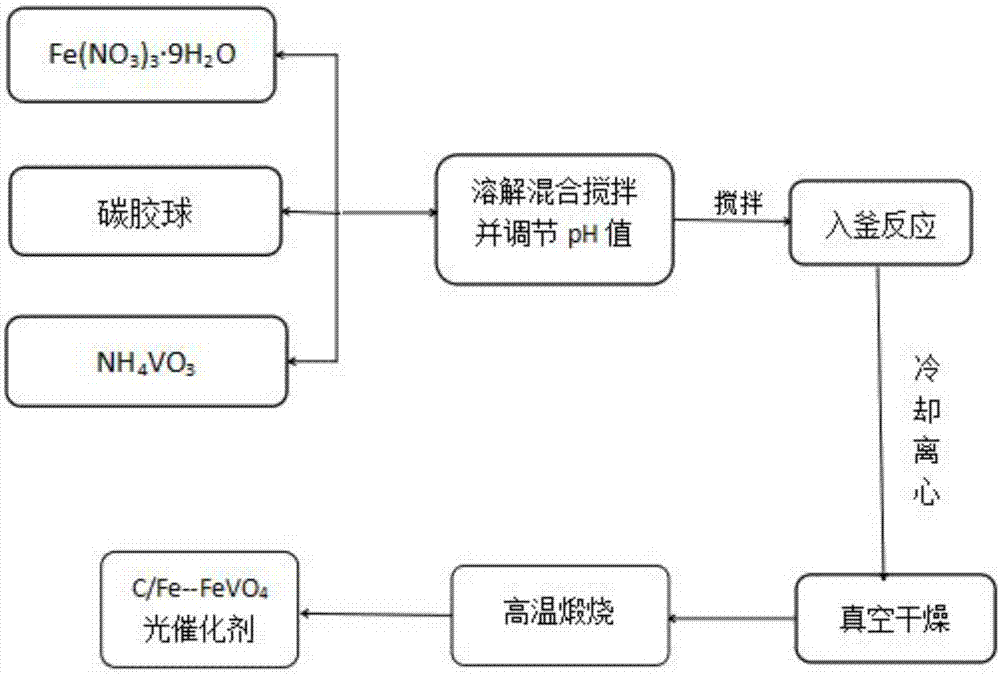

[0036] Specific implementation mode one: as figure 1 As shown, this embodiment discloses a C / Fe-FeVO 4 The preparation method of composite photocatalyst, this method comprises the following steps:

[0037] Step 1. Mix glucose and ferrous gluconate, add deionized water and stir until clarification and dissolve all substances, place in a hydrothermal reaction kettle, react at 160°C for 8 hours, and take out the reaction kettle after it cools down naturally , followed by washing with deionized water and absolute ethanol, and vacuum-drying the washed precipitate to obtain the desired carrier carbon gel beads;

[0038] Step 2: Get the carbon rubber balls prepared in step 1 and add them to deionized water for ultrasonic treatment. After that, Fe(NO 3 ) 3 9H 2 O, NH 4 VO 3 and SDBS surfactant, after adding in the carbon rubber balls and mixing, continue to carry out ultrasonic treatment, then stir until fully mixed, use 2mol / LHNO 3 Or 1mol / LNaOH and then adjust the pH value o...

specific Embodiment approach 2

[0042] Specific embodiment two: this embodiment is a further description of specific embodiment one. In step one, the glucose and ferrous gluconate are mixed in a ratio of 1:0.6 by mass ratio, and deionized water is added and stirred until Clarify and dissolve all substances, the ratio of glucose to deionized water is (0.4-1g): (40-100mL), and the washed precipitate is vacuum-dried at 40° for 4 hours.

[0043] This embodiment is mainly judged according to the level of photocatalytic degradation effect of photocatalytic oxidation of ciprofloxacin, etc., under this condition, the removal rate of ciprofloxacin is relatively high.

specific Embodiment approach 3

[0044] Specific embodiment three: This embodiment is a further description of specific embodiment one. In step two, the ratio of the carbon rubber balls to deionized water is (0.4-1) g: (40-100) mL , the ultrasonic treatment time is 10min, Fe(NO 3 ) 3 9H 2 O, NH 4 VO 3 and SDBS surfactant, after adding in the carbon rubber balls and mixing, the time for continuing ultrasonic treatment is 10min, with 2mol / LHNO 3 Or 1mol / L NaOH to adjust the pH=3 of the solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com