Preparation method for lithium bis(fluorosulfonyl)imide

A technology of lithium bisfluorosulfonyl imide and bisfluorosulfonimide, which is applied in the field of compound preparation, can solve the problems of high content of ionic impurities and low yield, and achieve simple preparation process, high yield and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] FSO 2 NH 2 +Li 2 CO 3 →FSO 2 NHL

[0023] SO 2 Cl 2 +KF→SO 2 f 2

[0024] FSO 2 NHLi+SO 2 f 2 +Py→FSO 2 NHSO 2 F·Py

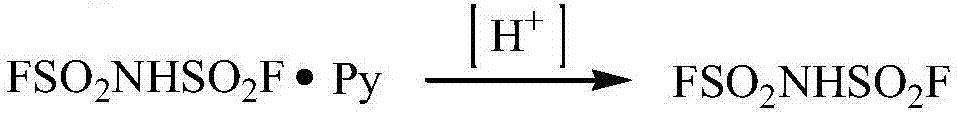

[0025]

[0026] FSO 2 NHSO 2 F+Li 2 CO 3 →FSO 2 NNSO 2 f

[0027] Add 49.5g (0.5mol) fluorosulfonamide in the reaction bottle of 500mL, add acetonitrile under ice-water bath as solvent, add 20.4g (0.275mol) lithium carbonate anhydrous, stir to neutrality, filter under reduced pressure, reduce after obtaining clear filtrate Dry under pressure to obtain the crude product of lithium fluorosulfonamide.

[0028] To a 500mL reaction flask, add the lithium fluorosulfonamide prepared in the previous step, add 200mL dry acetonitrile and 39.5g (0.5mol) pyridine, take an ice-water bath, take another 500mL reaction flask, add 135g (1mol) sulfuryl chloride, 200mL dicarbonate Ethyl ester, 69.6g (1.2mol) anhydrous potassium fluoride, magnetic stirring, temperature control 80 degrees, reaction flask connected to -20 degrees reflux condenser, th...

Embodiment 2

[0031] FSO 2 NH 2 +LiOH→FSO 2 NHL

[0032] SO 2 Cl 2 +NaF→SO 2 f 2

[0033] FSO 2 NHLi+SO 2 f 2 +(C 2 h 5 ) 3 N→FSO 2 NHSO 2 F·Py

[0034]

[0035] FSO 2 NHSO 2 F+LiOH→FSO 2 NNSO 2 f

[0036] Add 49.5g (0.5mol) fluorosulfonamide to a 500mL reaction flask, add acetonitrile as a solvent in an ice-water bath, add 6.6g (0.275mol) lithium hydroxide, stir until neutral, filter under reduced pressure, and depressurize after obtaining a clear filtrate After drying, the crude product of lithium fluorosulfonamide was obtained.

[0037] To a 500mL reaction flask, add the lithium fluorosulfonamide prepared in the previous step, add 200mL dry acetonitrile and 50.5g (0.5mol) triethylamine, take an ice-water bath, take another 500mL reaction flask, add 135g (1mol) sulfuryl chloride, 200mL Diethyl carbonate, 50.4g (1.2mol) anhydrous sodium fluoride, magnetic stirring, temperature control 80 degrees, the reaction bottle is connected to a reflux condenser at -20 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com