Research of porous graphene material in capacitive deionization

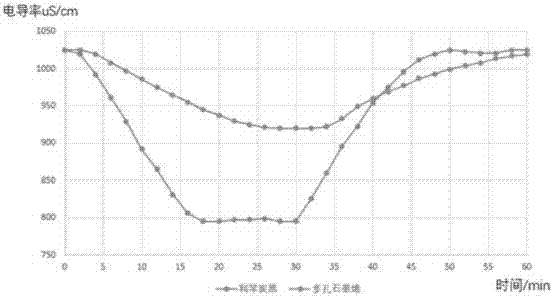

A capacitive deionization and graphene technology, which is applied in the field of seawater desalination, can solve the problems of poor wettability and low desalination efficiency, and achieve the effect of increasing adsorption capacity, high specific surface area, high adsorption capacity and desalination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

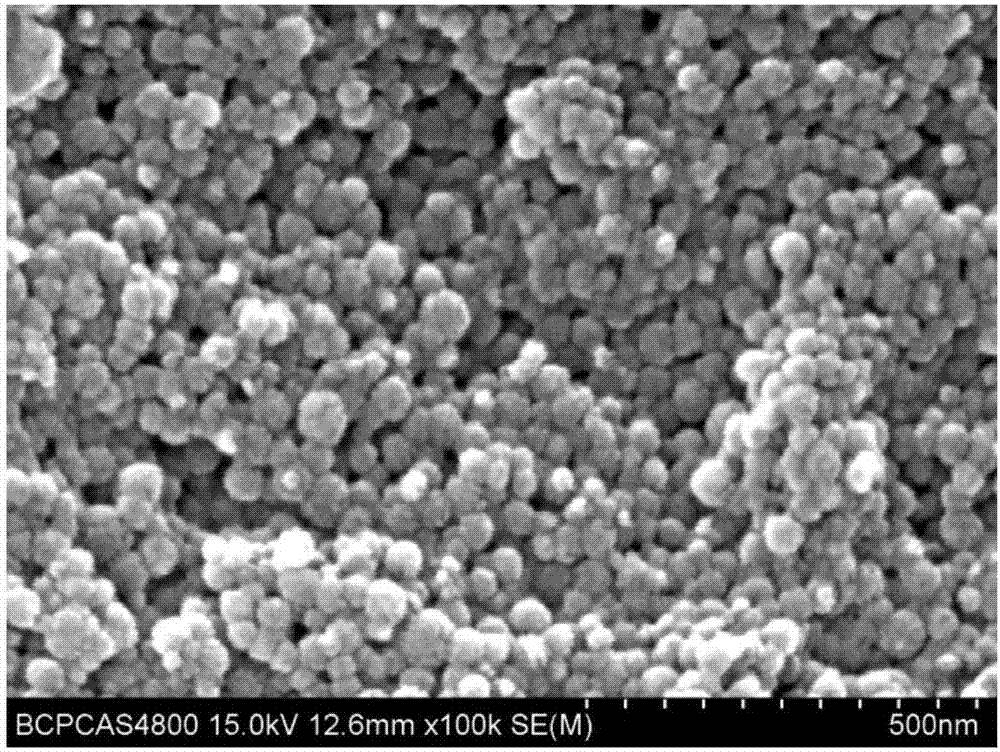

[0026] (1) Add 10ml of styrene and 1ml of methacrylic acid to a 250ml three-neck flask in turn, then add 90ml of distilled water, stir and mix at a medium speed, then add 0.1g of sodium lauryl sulfate, and heat up to 70°C under nitrogen protection. ℃, stir at a medium speed until uniform, usually more than 30 minutes. Then add 0.05g of potassium persulfate, stir at 400r / min, and react for 24h. After cooling to room temperature, a milky white mixed solution was obtained, which was carboxyl-modified polystyrene microspheres.

[0027] (2) Add 50 mg of graphene oxide to 47.5 ml of water, and disperse it with an ultrasonic device for 2 hours to obtain a brown-yellow solution. Add 2.5ml of the above mixed solution, stir and mix well, add 3-4 drops of ammonia water dropwise, and stir at 200r / min for 2h. Then add 0.1g of thiourea and continue to stir at 200r / min for 1h.

[0028] (3) Put the above solution into a 60ml reaction kettle, and heat it with water at 160°C for 5h. Filter ...

Embodiment 2

[0033] (1) Dry Ketjen Black and reserve it for later use.

[0034] (2) Dissolve 0.4g of Ketjen black, 0.05g of conductive carbon black, and 0.05g of PTFE in 30ml of deionized water, and ultrasonically disperse and mix for 30min.

[0035] (3) Keep the temperature of the water bath at 80°C, fix the cut graphite paper on the top of the water bath, drop the above solution onto the graphite paper in batches, disperse evenly by rolling with a glass rod, and continue to drip after the solvent is evaporated to dryness. Add with a roller until the dripping is complete. The electrode sheets were dried in a vacuum oven and then reserved for use.

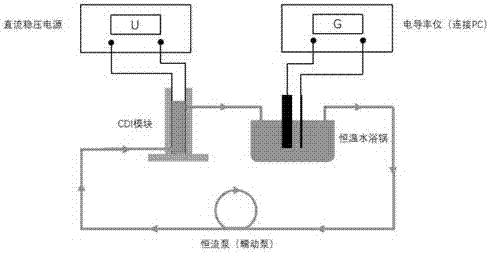

[0036] Assembly of the capacitive deionization unit

[0037] The capacitive deionization device (that is, the seawater desalination module) is self-made, and the principle refers to the attached image 3 . The prepared electrode sheets were cut into two pieces of the same size and weighed. Then insert into the self-made module, inject 20ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com