Epoxy resin thermal conductive composite material, preparation thereof and application

A heat-conducting composite material and epoxy resin technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, circuits, etc., can solve the problems of poor thermal conductivity, good thermal conductivity, high viscosity, etc., achieve high thermal conductivity and improve thermal conductivity coefficient, the effect of improving the interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

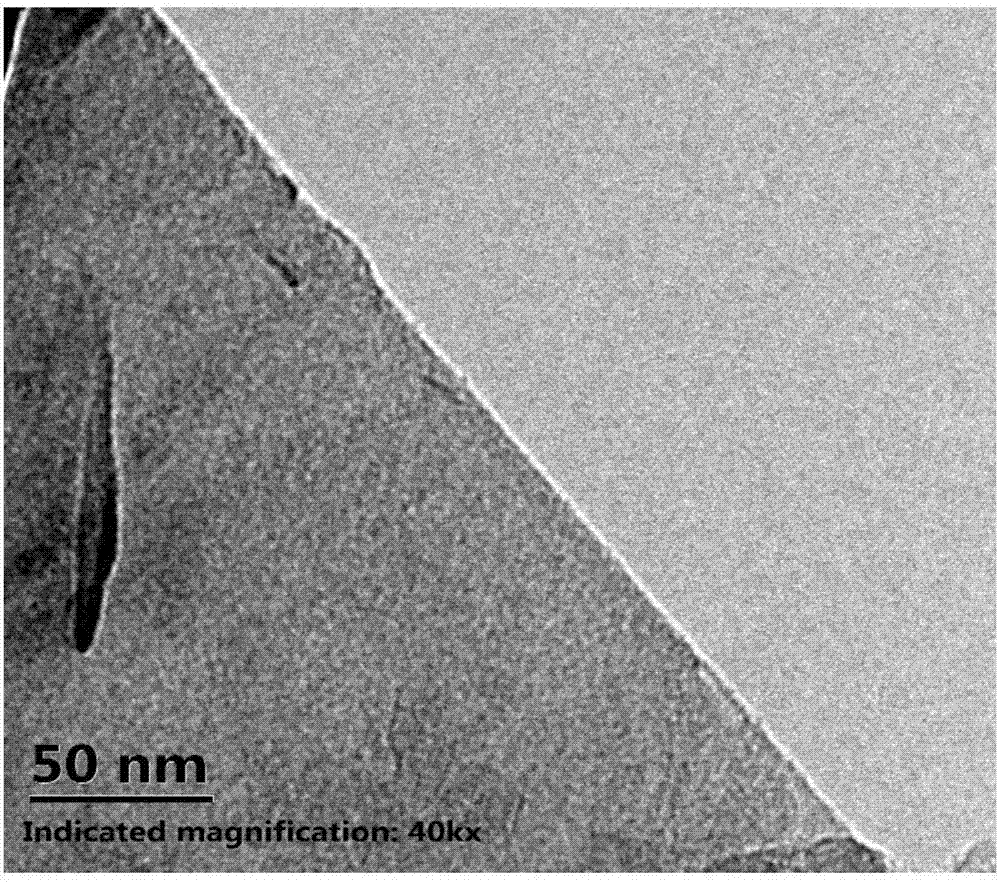

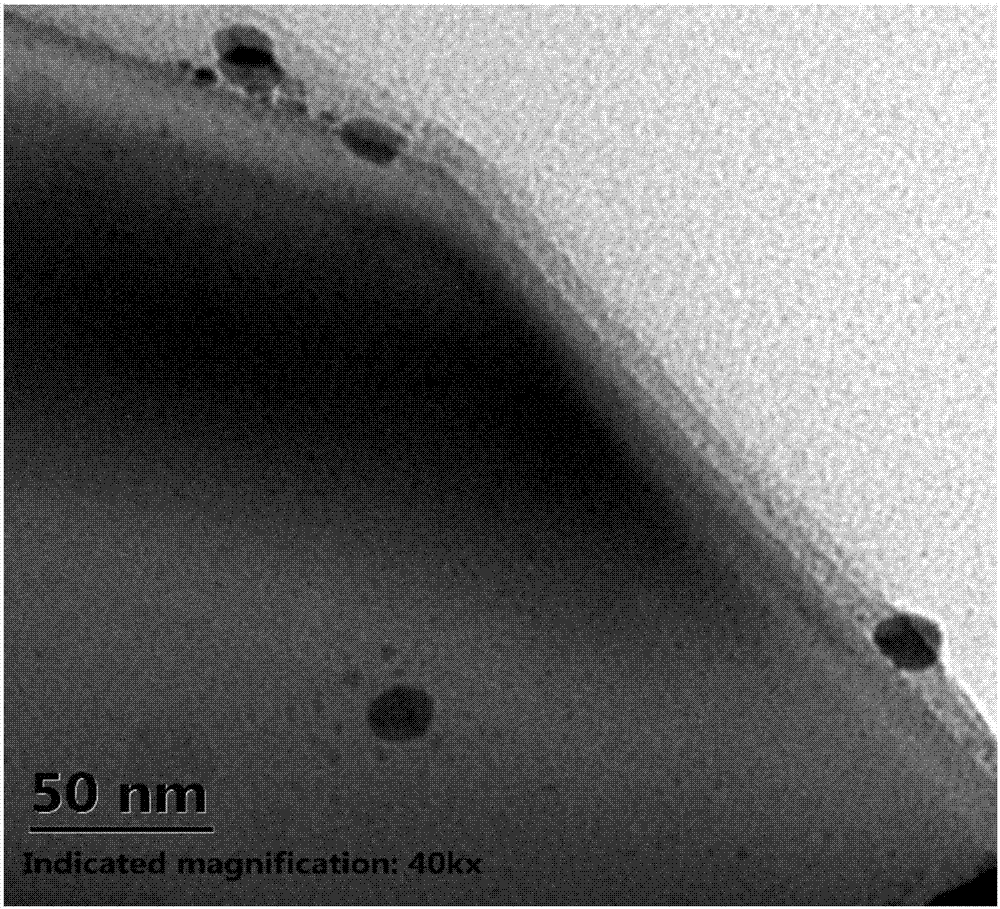

[0047] (1-1) Preparation of hydroxyl-modified boron nitride:

[0048] uniformly dispersing boron nitride in an alkaline aqueous solution to obtain a first dispersion system, wherein each gram of boron nitride corresponds to 100 ml to 500 ml of an alkaline aqueous solution, wherein the pH value of the alkaline aqueous solution is 11-13; Next, heat and stir the first dispersion at 40°C-60°C for 2-5 hours, then suction filter, wash, and dry to obtain hydroxyl-modified boron nitride;

[0049] (1-2) Preparation of boron nitride grafted with γ-mercaptopropyltrimethoxysilane:

[0050] Disperse the hydroxyl-modified boron nitride obtained in the step (1-1) into toluene, then add γ-mercaptopropyltrimethoxysilane, and heat the mixture at 60°C to 120°C under a protective atmosphere Heating to reflux for 3 to 12 hours, wherein each gram of hydroxyl-modified boron nitride corresponds to 100 milliliters to 300 milliliters of toluene, and 1 milliliter to 3 milliliters of γ-mercaptopropyltri...

Embodiment 1

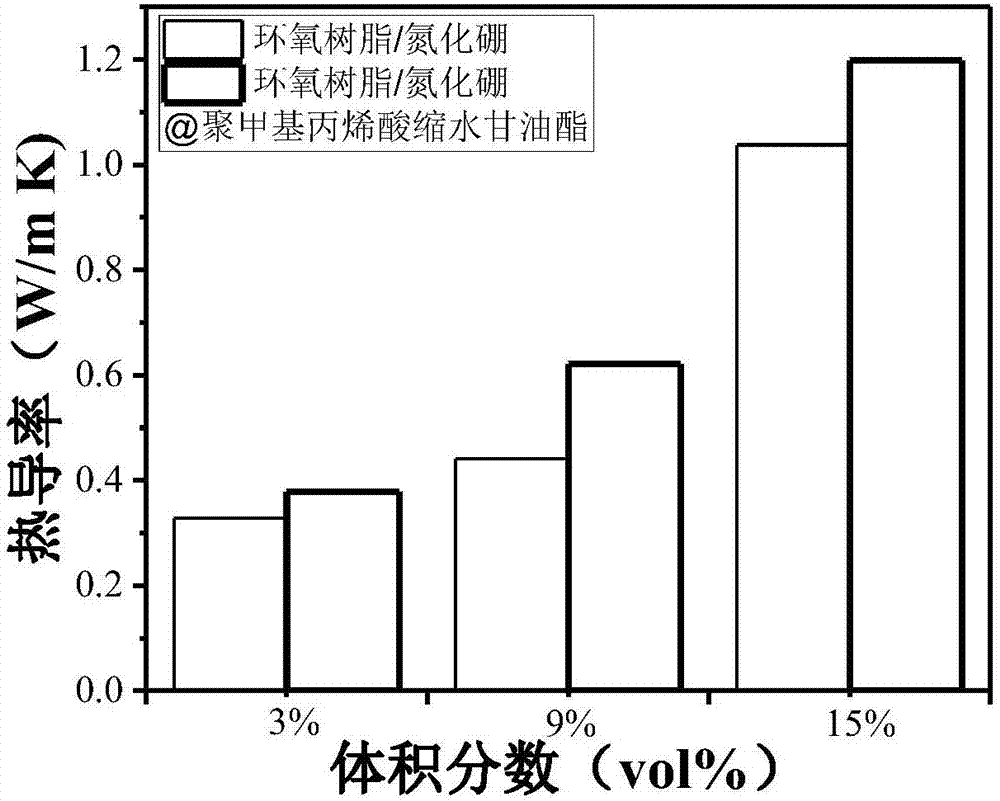

[0062] In the epoxy resin composite material in this embodiment, 3% by volume boron nitride filler is uniformly dispersed in the epoxy resin, and the average particle diameter of the boron nitride inorganic filler is 40 microns. The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, the thermal conductivity is 0.23W / m·K, and the viscosity is 2.6Pa·s at 30°C.

[0063] The epoxy resin composite material is prepared according to the following method according to the formula ratio:

[0064] (1) Take boron nitride and fully dry the filler.

[0065] (2) Add the boron nitride obtained in the step (1) to the epoxy resin, disperse it uniformly, and solidify after degassing to obtain the epoxy resin composite material. Described epoxy resin is bisphenol A type epoxy resin; Described curing agent is imidazoles and acid anhydrides curing agent, and the addition amount of acid anhydrides curing agent is 85wt.% of epoxy resin, an...

Embodiment 2

[0072] In the epoxy resin composite material in this embodiment, boron nitride filler with a volume ratio of 9% is uniformly dispersed in the epoxy resin, and the average particle diameter of the boron nitride inorganic filler is 40 microns. The thermal conductivity of the epoxy resin composite material is tested according to the test standard ASTM C1113, the thermal conductivity is 0.44W / m·K, and the viscosity is 5.1Pa·s at 30°C.

[0073] The epoxy resin composite material is prepared according to the following method according to the formula ratio:

[0074] (1) Take boron nitride and fully dry the filler.

[0075] (2) Add the boron nitride obtained in the step (1) to the epoxy resin, disperse it uniformly, and solidify after degassing to obtain the epoxy resin composite material. Described epoxy resin is bisphenol A type epoxy resin; Described curing agent is imidazoles and acid anhydrides curing agent, and the addition amount of acid anhydrides curing agent is 85wt.% of ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com