A malic acid-modified biocompatible pedot:pss highly conductive film and its application

A technology of biocompatibility and malic acid, applied in the field of high conductivity PEDOT:PSS film and its preparation, can solve problems such as poor wettability of spin-coating liquid, stimulation of pressure sensor, poor elasticity and brittleness of film, etc. Inexpensive, good film-forming properties, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

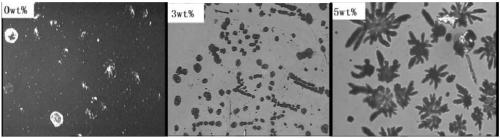

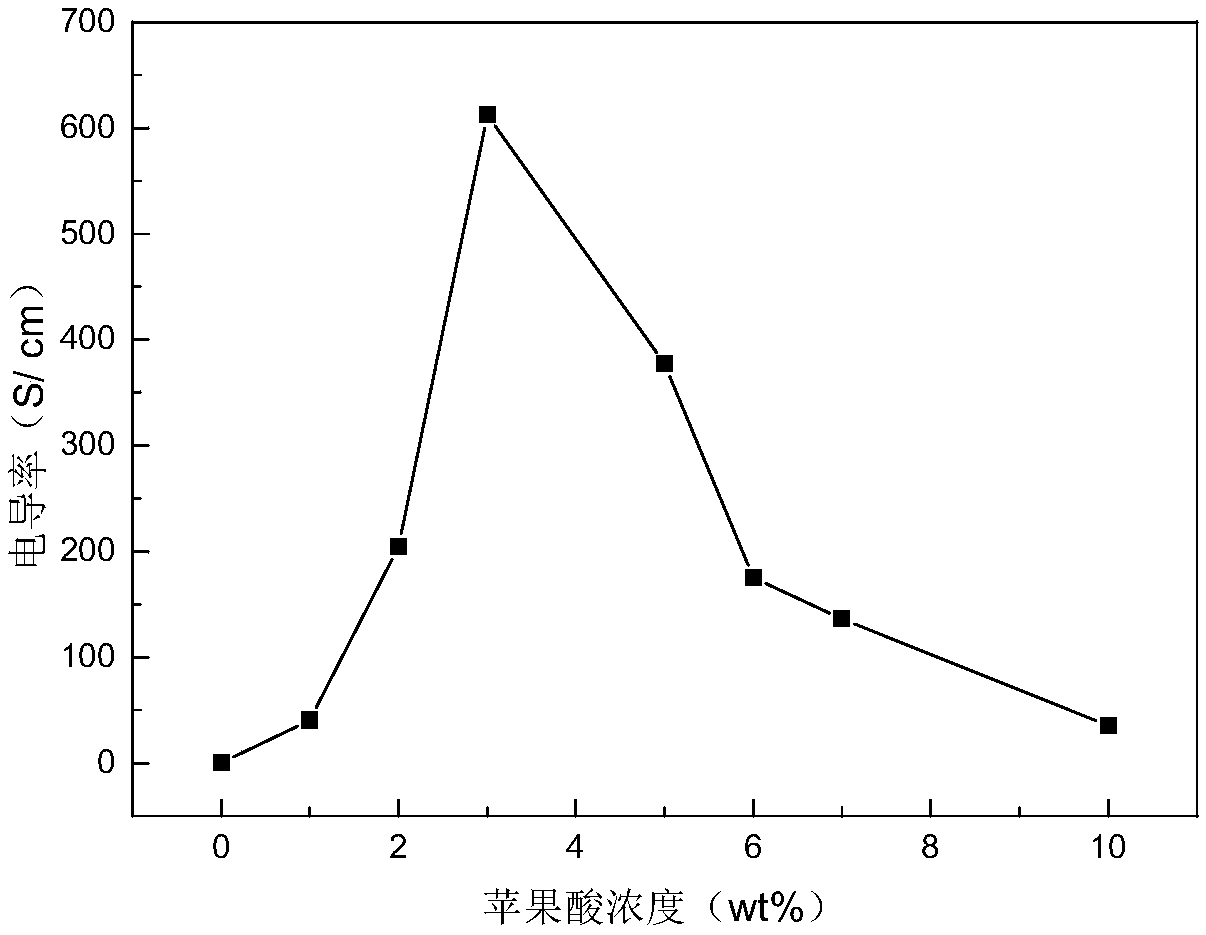

[0023] Example 1: Biocompatible PEDOT:PSS highly conductive film (i.e. intrinsic PEDOT:PSS film) when the concentration of DL-malic acid is 0wt%

[0024] Concrete preparation is carried out as follows:

[0025] 1. The substrate was pretreated in a UV-Ozone cleaning machine for 3 minutes, and then a monolayer of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane (SAM) was deposited in vacuum for surface evaporation. plating treatment.

[0026] 2. Stir the intrinsic PEDOT:PSS solution in a magnetic stirrer for 24 hours at room temperature.

[0027] 3. Drop the above solution onto the substrate treated in step a through a 0.45 μm polytetrafluoroethylene syringe filter, and spin-coat at a speed of 700 rpm for 30 seconds.

[0028] 4. At room temperature, place the spin-coated sample in a fume hood to dry for 24 hours, then solidify and release the mold.

[0029] 5. Connect the four probes to the digital source meter Keithly 2400, and use the four probe method to measure the resisti...

Embodiment 2

[0030] Example 2: Biocompatible PEDOT at the time of DL-malic acid concentration 1wt%:PSS high conductivity film

[0031] Concrete preparation is carried out as follows:

[0032] 1. The substrate was pretreated in a UV-Ozone cleaning machine for 3 minutes, and then a monolayer of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane (SAM) was deposited in vacuum for surface evaporation. plating treatment.

[0033] 2. Add DL-malic acid with a mass fraction of 1 wt% into the PEDOT:PSS solution, and add an appropriate amount of chemical cross-linking agent (3-Glycidyloxypropyl) trimethoxysilane.

[0034] 3. Stir the DL-malic acid-modified PEDOT:PSS mixed solution in a magnetic stirrer for 24 hours at room temperature to make it evenly mixed.

[0035] 4. Drop the above mixed solution onto the substrate treated in step a through a 0.45 μm polytetrafluoroethylene syringe filter, and spin-coat at a speed of 700 rpm for 30 s.

[0036] 5. At room temperature, place the spin-coated sample ...

Embodiment 3

[0038] Example 3: Biocompatible PEDOT at DL-malic acid concentration of 2wt%:PSS high conductivity film

[0039] Concrete preparation is carried out as follows:

[0040] 1. The substrate was pretreated in a UV-Ozone cleaning machine for 3 minutes, and then a monolayer of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane (SAM) was deposited in vacuum for surface evaporation. plating treatment.

[0041] 2. Add DL-malic acid with a mass fraction of 2wt% into the PEDOT:PSS solution, and add an appropriate amount of chemical cross-linking agent (3-Glycidyloxypropyl) trimethoxysilane.

[0042] 3. Stir the DL-malic acid-modified PEDOT:PSS mixed solution in a magnetic stirrer for 24 hours at room temperature to make it evenly mixed.

[0043] 4. Drop the above mixed solution onto the substrate treated in step a through a 0.45 μm polytetrafluoroethylene syringe filter, and spin-coat at a speed of 700 rpm for 30 s.

[0044]5. At room temperature, place the spin-coated sample in a fume h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com