Efficient coating used for boiler water pump

A furnace water pump and coating technology, which is applied in the field of circulating pumps, can solve the problems that the pump coating is difficult to achieve high temperature resistance and high production costs, and achieve significant economy and safety, material and production costs, and use effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

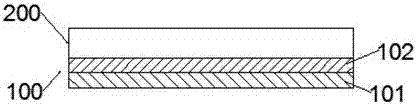

[0012] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0013] A high-efficiency coating for a furnace water pump, comprising an anti-corrosion coating 200 and a high-temperature strong acid-resistant layer 100, the components of 200 parts by mass of the anti-corrosion coating are: 45 parts of polyvinyl acetate, 55 parts of zinc chromate, iron yellow 10 parts, 95 parts of butyl acrylate, 20 parts of dimethyl phthalate, 10 parts of acetic acid, 4 parts of sodium acetate, 15 parts of trisodium phosphate, 5 parts of methyl methacrylate, 15 parts of ammonium acrylate, isopropyl acrylate 10 parts of ester, 13 parts of butyl acetate, 8 parts of ammonium persulfate, 5 parts of dry triol, 7 parts of urea;

[0014] The high temperature resistant strong acid layer 100 includes a working layer 101 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com