Cable bridge having fireproof function

A technology for cable bridges and bridges, which is applied in the direction of fireproof coatings, electrical components, coatings, etc., can solve the problems of reduced mechanical strength, reduced compressive strength, and loss of support ability, so as to improve hardness and toughness, reduce environmental pollution, and improve The effect of uniformity and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

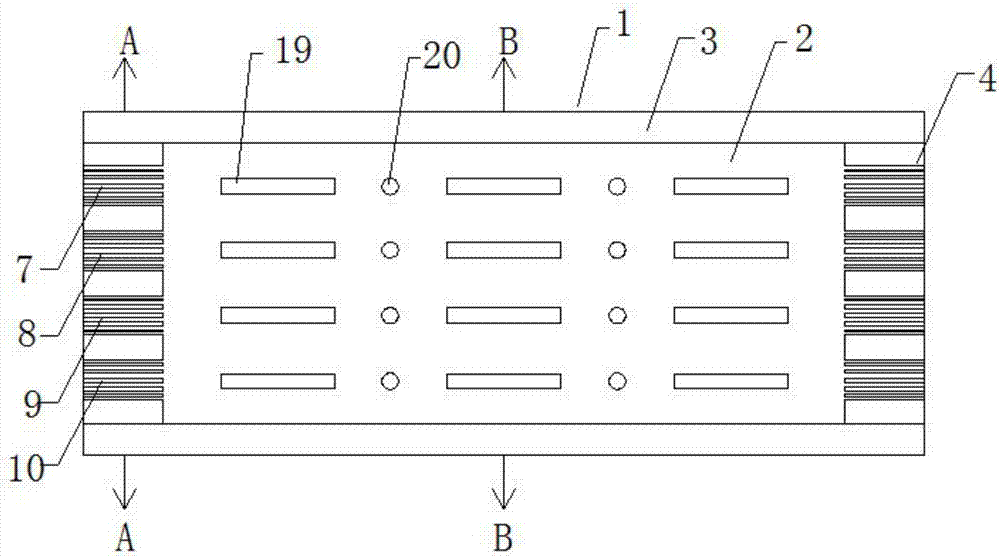

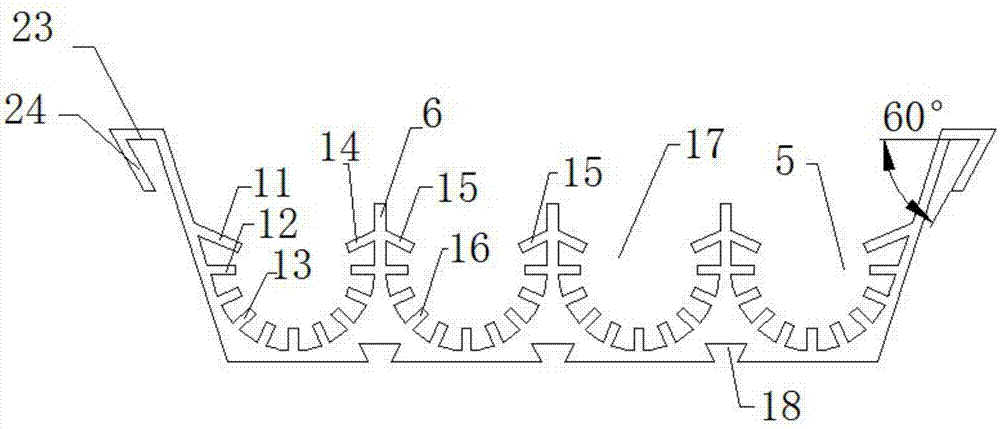

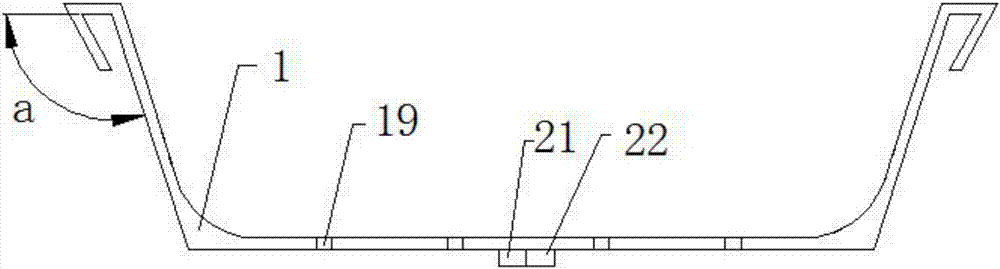

[0025] As shown in the figure, a cable bridge frame with fire protection function includes a bridge frame body, the cross section of the bridge frame body is an isosceles trapezoid, the bridge frame body includes a bottom plate, a side plate, and two sides of the bridge frame body are provided with connecting pieces, and the connecting pieces include Horizontal plate and vertical plate, the horizontal plate is bent down 60° to form a vertical plate, the angle a between the horizontal plate and the side plate is 110°, the bridge body is provided with a partition device, and the partition device is located at both ends of the bridge body , The partition device includes a partition groove and a baffle located between adjacent partition grooves, the cross section of the baffle is a rectangular structure, and the partition groove includes a first partition groove, a second partition groove, a third partition groove, and a fourth partition groove, The first separation groove, the seco...

Embodiment 2

[0036] The difference from Example 1 is that the preparation steps of the fireproof coating are as follows:

[0037] (1) In terms of weight fraction, weigh out 80 parts of light calcium carbonate, 40 parts of wollastonite, 20 parts of styrene-butadiene emulsion, 80 parts of n-butanol, 20 parts of organic phosphate, 10 parts of cobalt isooctanoate, and 5 parts of cerium isooctanoate. Parts, 20 parts of melamine, 10 parts of preservative;

[0038] (2) Add the preservative, n-butanol, and styrene-butadiene emulsion to the mixer and mix evenly, the stirring temperature is 70°C, and the stirring time is 1 hour to obtain a mixed emulsion;

[0039] (3) Add light calcium carbonate, wollastonite, organic phosphate, cobalt isooctanoate, cerium isooctanoate, and melamine into a vertical ball mill in the order of powder first and liquid material, and after ball milling for 0.5 h, the mixture is obtained ;

[0040] (4) Add the mixture to the mixer, then slowly add the mixed emulsion, stir and mix...

Embodiment 3

[0043] The difference from Example 1 is that the preparation steps of the fireproof coating are as follows:

[0044] (1) In terms of weight fraction, weigh out 80 parts of light calcium carbonate, 40 parts of wollastonite, 20 parts of styrene-butadiene emulsion, 50 parts of n-butanol, 10 parts of chloropropane, 8 parts of cobalt isooctanoate, and 4 parts of cerium isooctanoate. Parts, 20 parts of brominated epoxy resin, 20 parts of preservative;

[0045] (2) Add the preservative, n-butanol, and styrene-butadiene emulsion to the mixer and mix evenly, the stirring temperature is 50°C, and the stirring time is 1 hour to obtain a mixed emulsion;

[0046] (3) Add light calcium carbonate, wollastonite, oxychloropropane, cobalt isooctanoate, cerium isooctanoate, and brominated epoxy resin to the vertical ball mill in the order of powder first and liquid, and the ball mill 0.5h After that, a mixture is obtained;

[0047] (4) Add the mixture to the mixer, then slowly add the mixed emulsion, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com