Reflective heat-insulation composite liquid granite coating and preparation method thereof

A granite coating, liquid technology, applied in the field of coatings, can solve the problems of decoration without reflective heat insulation function, multi-color, and non-single color of water-based reflective heat insulation coatings, so as to speed up drying speed and improve construction performance. and the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

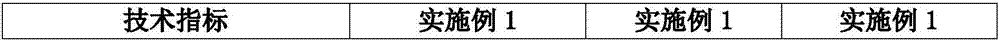

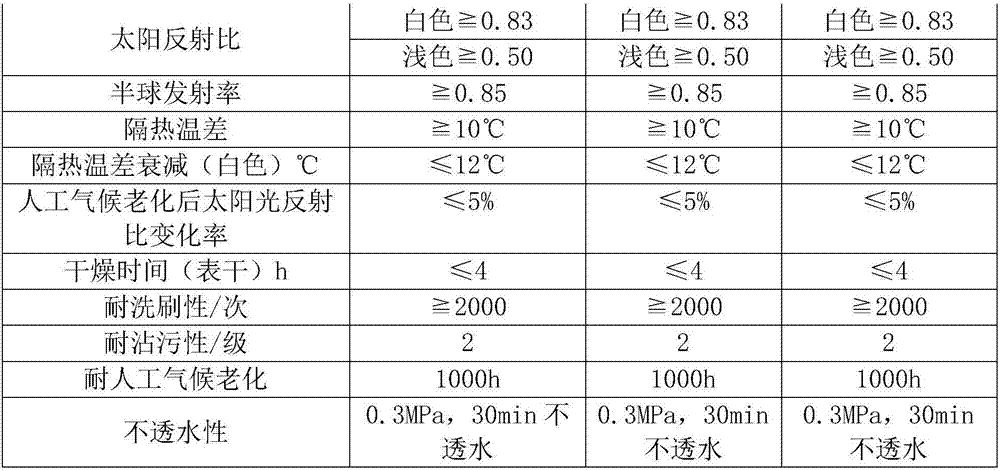

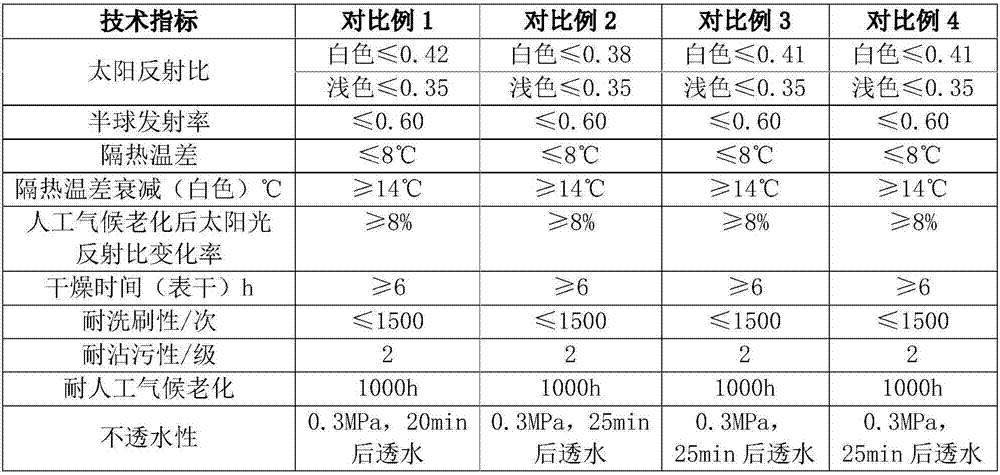

Embodiment 1

[0039] A reflective and heat-insulating composite liquid granite coating is composed of the following components in parts by weight:

[0040] 1. Main paint components of reflective heat insulation composite liquid granite coating:

[0041] Component A: deionized water, 15 parts; 0.6 parts of hydrophobic modified hydroxyethyl cellulose (hydroxyethyl cellulose: hydroxymethyl cellulose: hydrophobic agent = 1:1:1); 25 parts of various pigments and fillers 1 part, including kaolin: barium sulfate=1:1; 4 parts of various auxiliary agents, including dispersant, defoamer, wetting agent, preservative); 2 parts of film-forming aids (dodecyl alcohol ester: dipropylene glycol Methyl ether = 1:1); 30 parts of water-based silicone hybrid acrylic resin; 20 parts of reflective thermal insulation color paste, including 16 parts of Colorvista Cool and 4 parts of general-purpose heat reflective color paste; 15 parts of Shuredun reflective thermal insulation pigment , including a mixture of 7.5 ...

Embodiment 2

[0053] A reflective and heat-insulating composite liquid granite coating is composed of the following components in parts by weight:

[0054] 1. Main paint components of reflective heat insulation composite liquid granite coating:

[0055] Component A: deionized water, 14 parts; 0.7 parts of hydrophobic modified hydroxyethyl cellulose (hydroxyethyl cellulose: hydroxymethyl cellulose: hydrophobic agent = 1:1:1); various pigments and fillers 26 Parts, including kaolin: barium sulfate=1:2; 4 parts of various additives, including dispersant, defoamer, wetting agent, preservative); 2 parts of film-forming aids (dodecyl alcohol ester: dipropylene glycol Methyl ether = 1:1.5); 25 parts of water-based silicone hybrid acrylic resin; 18 parts of reflective thermal insulation color paste, including Colorvista Cool: general-purpose heat reflective color paste = 4:1; 15 parts of Shuredun reflective thermal insulation pigment , including Shuredun SP-150C: rutile titanium dioxide = 1:1 mixi...

Embodiment 3

[0067] A reflective and heat-insulating composite liquid granite coating is composed of the following components in parts by weight:

[0068] 1. Main paint components of reflective heat insulation composite liquid granite coating:

[0069] Component A: deionized water, 16 parts; 0.6 parts of hydrophobic modified hydroxyethyl cellulose (hydroxyethyl cellulose: hydroxymethyl cellulose: hydrophobic agent = 1:1:1); various pigments and fillers 25 Parts, including kaolin: barium sulfate=1:3; 4 parts of various additives, including dispersant, defoamer, wetting agent, preservative); 2 parts of film-forming aids (dodecyl alcohol ester: dipropylene glycol Methyl ether = 2:1); 30 parts of water-based silicone hybrid acrylic resin; 10 parts of reflective thermal insulation color paste, including Colorvista Cool: general-purpose heat reflective color paste = 4:1; 15 parts of Shuredun reflective thermal insulation pigment , including Soredun SP-150C pigment: rutile titanium dioxide = 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com