High density fermentation method of genetically engineered bacterium of recombinant interferon

A technology of genetically engineered bacteria and high-density fermentation, applied in the field of high-density fermentation of genetically engineered bacteria, can solve the problems of complicated purification process, limited application, moderate effect, etc. The effect of industrial production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

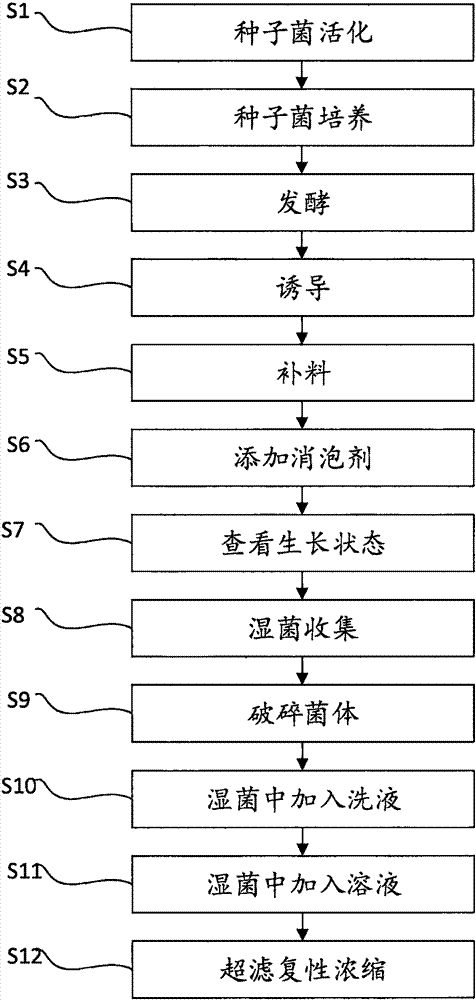

[0040] Such as figure 1 Shown, a kind of high-density fermentation method of recombinant interferon genetically engineered bacterium comprises the following steps:

[0041] S1: Activation of seed bacteria, thaw the working seed bacteria stored in liquid nitrogen in a 37°C water bath, then inoculate KaNa / bacteria in a 15ml centrifuge tube at a ratio of 1:1000, and use a rotary constant temperature and speed-adjustable shaker for cultivation; control the speed at 220rpm / min, culture temperature 37℃, culture time 8-9h;

[0042] S2: Seed bacteria culture: Expand the activated strains and transfer them to a 500ml Erlenmeyer shaker flask, continue to use a rotary constant temperature and speed-adjustable shaker for cultivation; control the rotation speed at 220rpm / min, cultivate at a temperature of 3737°C, and cultivate for 16-17 hours;

[0043] S3 fermentation: put the cultured seed solution into the fermenter at a ratio of 1:1000 for fermentation, the fermentation medium is 3L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com