Methylallyl alcohol random polyether and preparation method thereof

A technology of methallyl alcohol and random polyether, which is applied in the field of methallyl alcohol random polyether and its preparation, which can solve the problem that the reaction is difficult to control, cannot explain the polymer surfactant, the variety of monomers, etc. problems, to reduce the chemical process time, save the investment of slicing equipment, and improve the dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

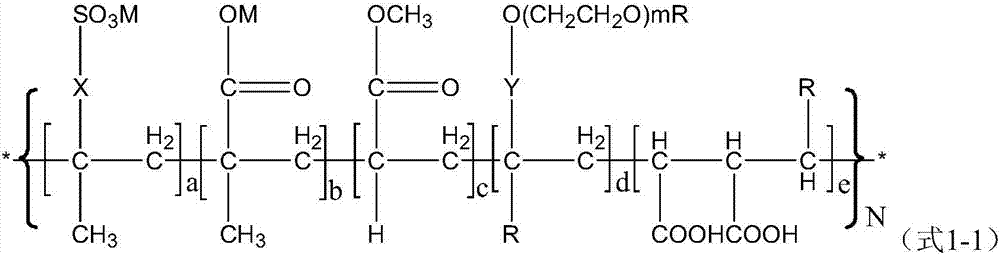

Image

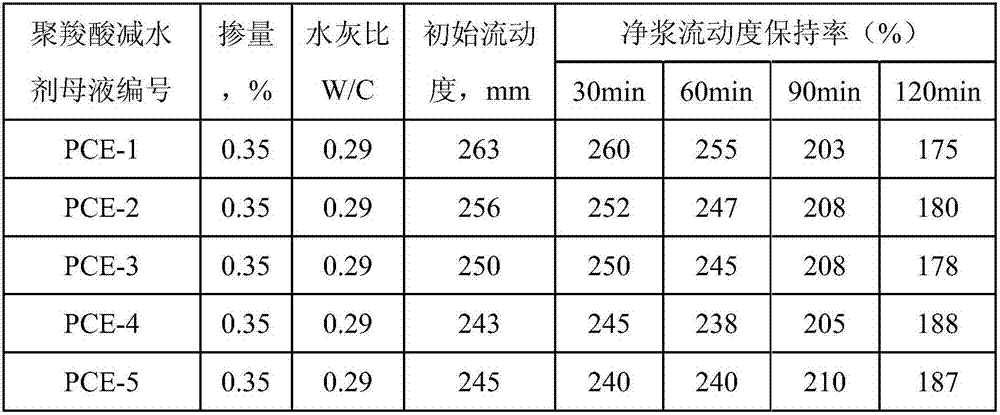

Examples

Embodiment 1

[0051] A kind of preparation method of methallyl alcohol random polyether of the present embodiment, comprises the steps:

[0052] 1) Add 21.6 parts by weight of methallyl alcohol into the reaction kettle, add 0.45 parts by weight of catalyst metal sodium within 30 minutes, control the reaction temperature to 20-30°C, and the reaction time is 0.5h; after the reaction, put the product into In 411 parts by weight of methallyl alcohol, nitrogen is replaced, the temperature is raised to 90°C, and a mixture of 1970.7 parts by weight of ethylene oxide and propylene oxide (mass ratio is about 69:47) is introduced, and the reaction temperature is controlled to be 90-90°C. 105°C, the reaction time is 4.0h; after the reaction, the temperature is lowered to 40°C and discharged to obtain a methallyl alcohol random polyether oligomer with a molecular weight of 400.

[0053] 2) Add 90 parts by weight of step 1) in the reaction kettle to obtain the methallyl alcohol random polyether oligomer...

Embodiment 2

[0055] A kind of preparation method of methallyl alcohol random polyether of the present embodiment, comprises the steps:

[0056] 1) Add 18.8 parts by weight of methallyl alcohol into the reactor, add 0.32 parts by weight of catalyst metal potassium within 50 minutes, control the reaction temperature to 25-35°C, and the reaction time is 0.5h; after the reaction, put the product into In 200.5 parts by weight of methacrylic acid, replace with nitrogen, raise the temperature to 90°C, feed 1151.3 parts by weight of a mixture of ethylene oxide and propylene oxide (mass ratio is about 138:103), and control the reaction temperature to 90-105 °C, the reaction time is 5.0 h; after the reaction, the temperature is lowered to 40 °C and discharged to obtain a methallyl alcohol random polyether oligomer with a molecular weight of 450.

[0057] 2) Add 84 parts by weight of step 1) in the reaction kettle to obtain the molecular weight of methallyl alcohol random polyether oligomer of 450, a...

Embodiment 3

[0059] A kind of preparation method of methallyl alcohol random polyether of the present embodiment, comprises the steps:

[0060]1) Add 17 parts by weight of methallyl alcohol into the reaction kettle, add 0.21 parts by weight of sodium metal and 0.21 parts by weight of metal potassium catalyst within 50 minutes, control the reaction temperature to 30-40 °C, and the reaction time is 0.8h; the reaction is over Then put the product into 159.4 parts by weight of methallyl alcohol, replace it with nitrogen, raise the temperature to 90°C, and feed in a mixture of 926.1 parts by weight of ethylene oxide and alkoxypropane (mass ratio is about 345:262), The reaction temperature is controlled at 90-105°C, and the reaction time is 5.5h; after the reaction, the temperature is lowered to 40°C and discharged to obtain a methallyl alcohol random polyether oligomer with a molecular weight of 450.

[0061] 2) Add 84 parts by weight of the methallyl alcohol random polyether oligomer with mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com