Adhesive zigzag piece-based steel fiber concrete assembled steel bridge panel

A technology of steel fiber reinforced concrete and steel bridge deck, which is applied in the direction of bridges, bridge parts, bridge construction, etc., to achieve the effect of improving durability, good combination effect and controlling construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

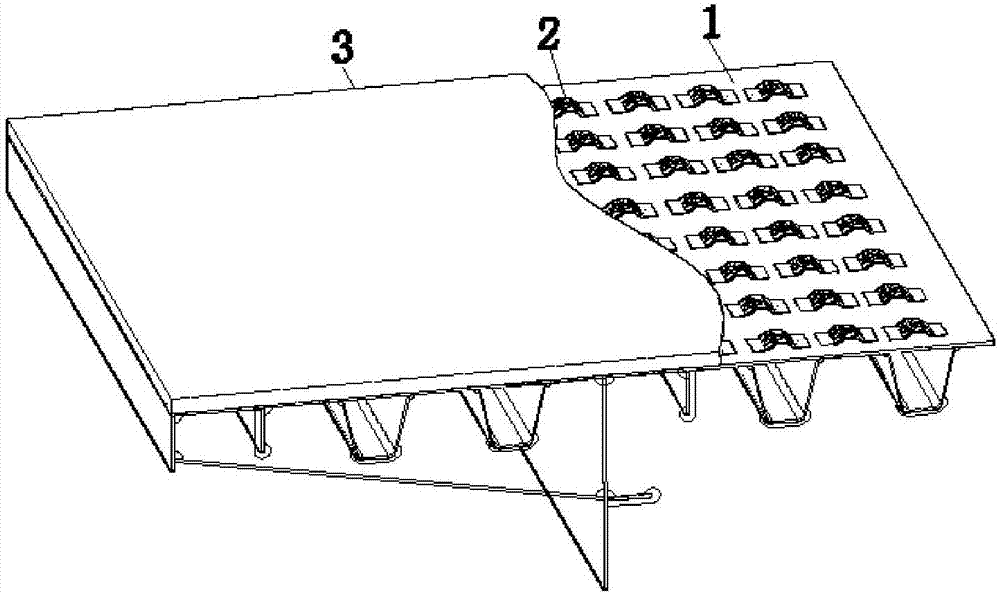

[0045] exist figure 1 , 2 Among them, the present invention is based on the steel fiber concrete composite steel bridge deck of bonded corrugated parts, which has the following steps:

[0046] S1. Use a high-pressure air gun to remove dust and clean the steel bridge deck cover plate 1;

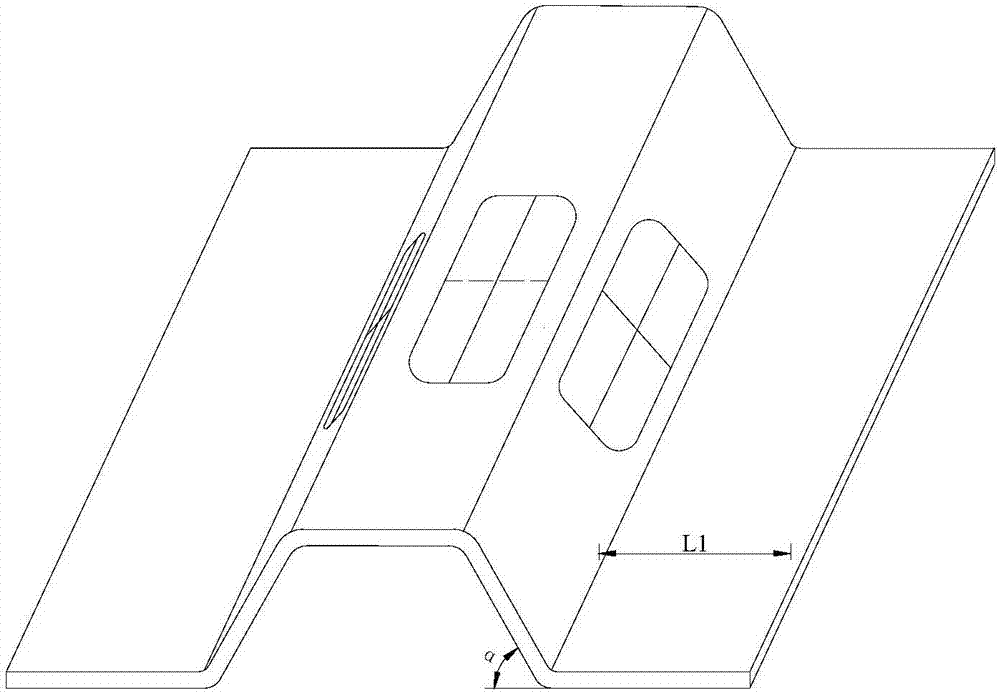

[0047] S2. On the steel bridge deck cover plate 1, use epoxy resin to bond and install the twisted shear connector 2. The thickness of the epoxy resin in this embodiment is 2-4 mm. The selection conditions for the epoxy resin in this embodiment are: : (a) suitable for bonding steel plate and steel plate, steel plate and concrete; (b) suitable for bridge structural components; (c) compressive strength, shear strength, elastic modulus, and shear modulus must meet the structural force requirements ; (d) The hardening time should not be less than 10 hours to ensure sufficient construction time. In this embodiment, Sika epoxy resin is used for bonding. In terms of construction feasibility, the e...

Embodiment 2

[0066] by 1m 3 The ultra-high performance steel fiber reinforced concrete as an example, in 1m 3 The ultra-high performance steel fiber reinforced concrete is composed of the following mass ratio materials:

[0067]

[0068] The above cement is PO425 cement; the particle distribution range of silica fume is 0.1-0.15μm, and the surface area is 15-27m 2 / g; the maximum particle size of the standard sand is less than 0.5mm; the steel fiber is copper-plated steel fiber with a length of 13mm and a diameter of 0.16mm; the model of the water reducer is Sika water reducer, which contains 2 components , A component is Sika 3301c high-efficiency superplasticizer, B component is Sika microbead powder, and the combination of A and B can improve the effect of the superplasticizer; the water is tap water.

[0069] Its preparation method is the same as Example 1 as follows.

Embodiment 3

[0071] by 1m 3 The ultra-high performance steel fiber reinforced concrete as an example, in 1m 3 The ultra-high performance steel fiber reinforced concrete is composed of the following mass ratio materials:

[0072]

[0073]

[0074] The above cement is PO425 cement; the particle distribution range of silica fume is 0.1-0.15μm, and the surface area is 15-27m 2 / g; the maximum particle size of the standard sand is less than 0.5mm; the steel fiber is copper-plated steel fiber with a length of 13mm and a diameter of 0.16mm; the model of the water reducer is Sika water reducer, which contains 2 components , A component is Sika 3301c high-efficiency superplasticizer, B component is Sika microbead powder, and the combination of A and B can improve the effect of the superplasticizer; the water is tap water.

[0075] Its preparation method is identical with embodiment 1.

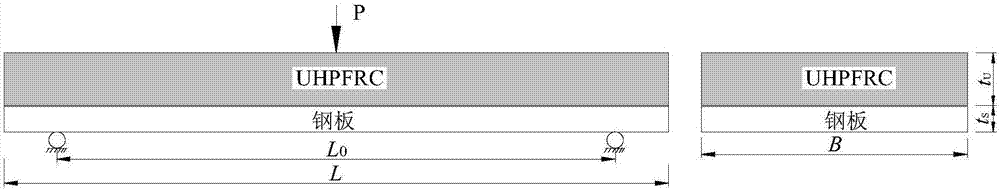

[0076] In order to verify the effectiveness of the design method proposed in the present invention, an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com