Method for preparing high-performance lithium-sulfur battery on basis of nitrogen-enriched molecule modified diaphragm

A lithium-sulfur battery and molecular technology, which is applied to battery components, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc., can solve the problems of difficulty in controlling the form of N, low content of N heteroatoms, and cumbersome preparation process. It is convenient for large-scale production, the equipment and production process are simple, and the raw materials are cheap and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

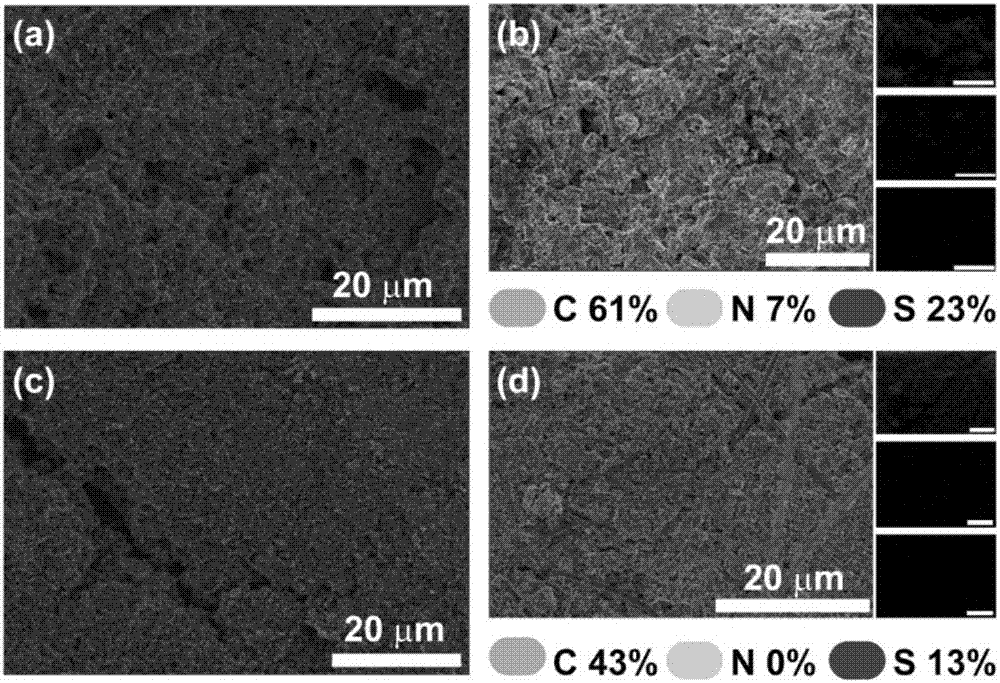

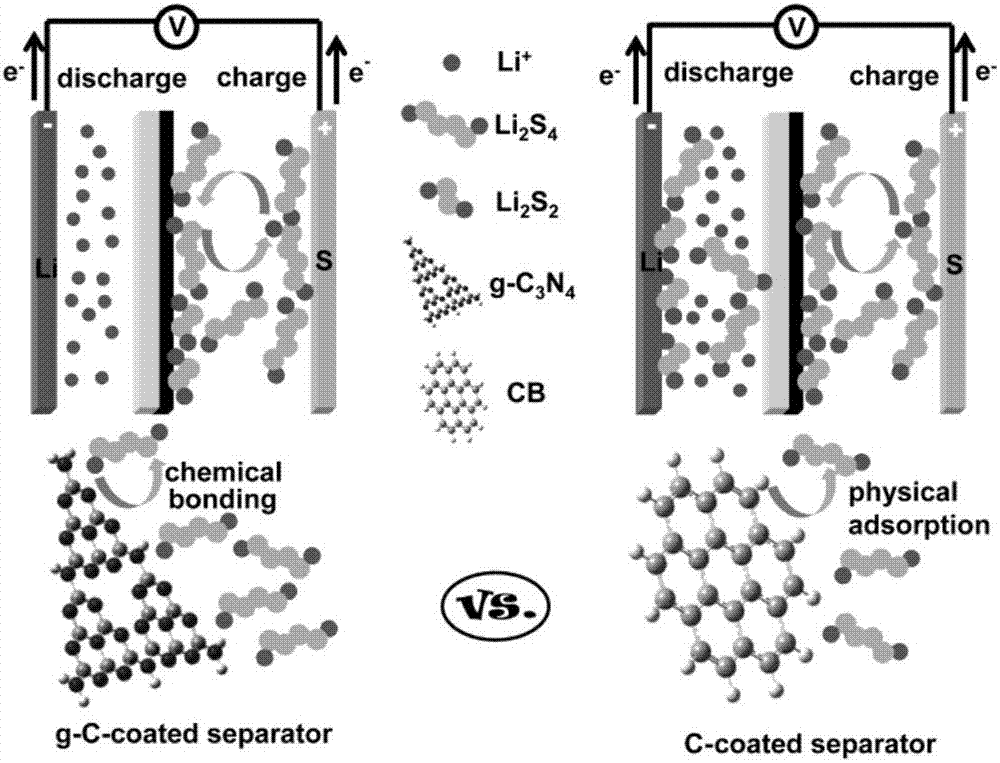

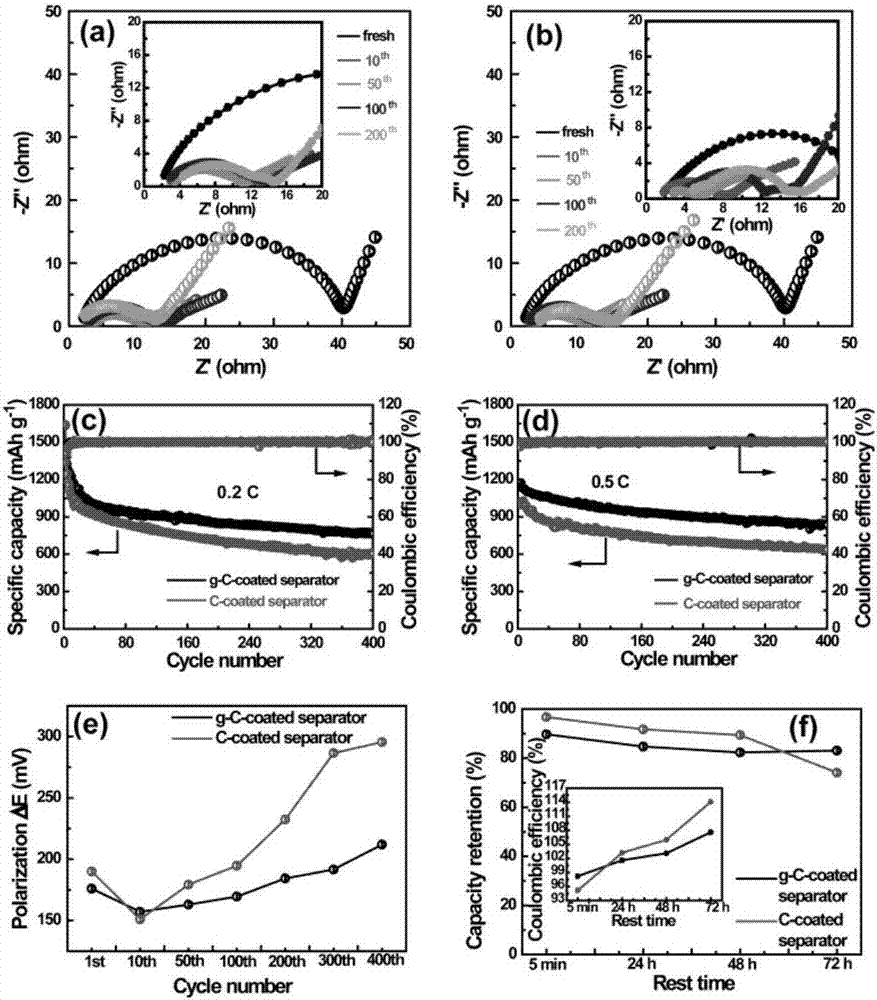

[0027] Take a certain amount of graphitized carbon nitride, a certain amount of conductive agent acetylene black, and a certain amount of binder PVDF, the mass ratio of the three is 6:3:1, add it to the mortar, and grind it thoroughly , to mix the three evenly, then transfer the mixture to a beaker, add a certain amount of dispersant NMP, the amount of dispersant should be appropriate to ensure a suitable viscosity, and then fully stir and mix evenly. Take out the commercial fiberglass separator needed to install the battery from the glove box, cut it into a suitable size, and then lay it flat. Spread the prepared slurry evenly on one side of the separator, and then transfer the separator to a vacuum oven. Vacuum dry at 60°C for 24 hours, then take out the separator, cut it into the diameter required for the button battery, and transfer it to the glove box again. When installing the battery, put the modified separator between the positive and negative electrodes, and coat it wi...

Embodiment 2

[0029]Take a certain amount of graphitized carbon nitride, a certain amount of conductive agent carbon nanofiber, and a certain amount of binder PVDF, the mass ratio of the three is 6:3:1, and add them to the mortar, fully Grind to make the three evenly mixed, then transfer the mixture to a beaker, add a certain amount of dispersant NMP, the amount of dispersant should be appropriate to ensure a suitable viscosity, then stir well and mix evenly. Take out the commercial fiberglass separator needed to install the battery from the glove box, cut it into a suitable size, and then lay it flat. Spread the prepared slurry evenly on one side of the separator, and then transfer the separator to a vacuum oven. Vacuum dry at 60°C for 24 hours, then take out the separator, cut it into the diameter required for the button battery, and transfer it to the glove box again. When installing the battery, put the modified separator between the positive and negative electrodes, and coat it with On...

Embodiment 3

[0031] Take a certain amount of graphitized carbon nitride, a certain amount of conductive agent acetylene black, and a certain amount of binder PVDF, the mass ratio of the three is 1:8:1, add it to the mortar, and grind it thoroughly , to mix the three evenly, then transfer the mixture to a beaker, add a certain amount of dispersant NMP, the amount of dispersant should be appropriate to ensure a suitable viscosity, then stir well and mix evenly. Take out the commercial fiberglass separator needed to install the battery from the glove box, cut it into a suitable size, and then lay it flat. Spread the prepared slurry evenly on one side of the separator, and then transfer the separator to a vacuum oven. Vacuum dry at 60°C for 24 hours, then take out the separator, cut it into the diameter required for the button battery, and transfer it to the glove box again. When installing the battery, put the modified separator between the positive and negative electrodes, and coat it with O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com