Moisture detection sensor, defect detection sensor, and sensor array using same

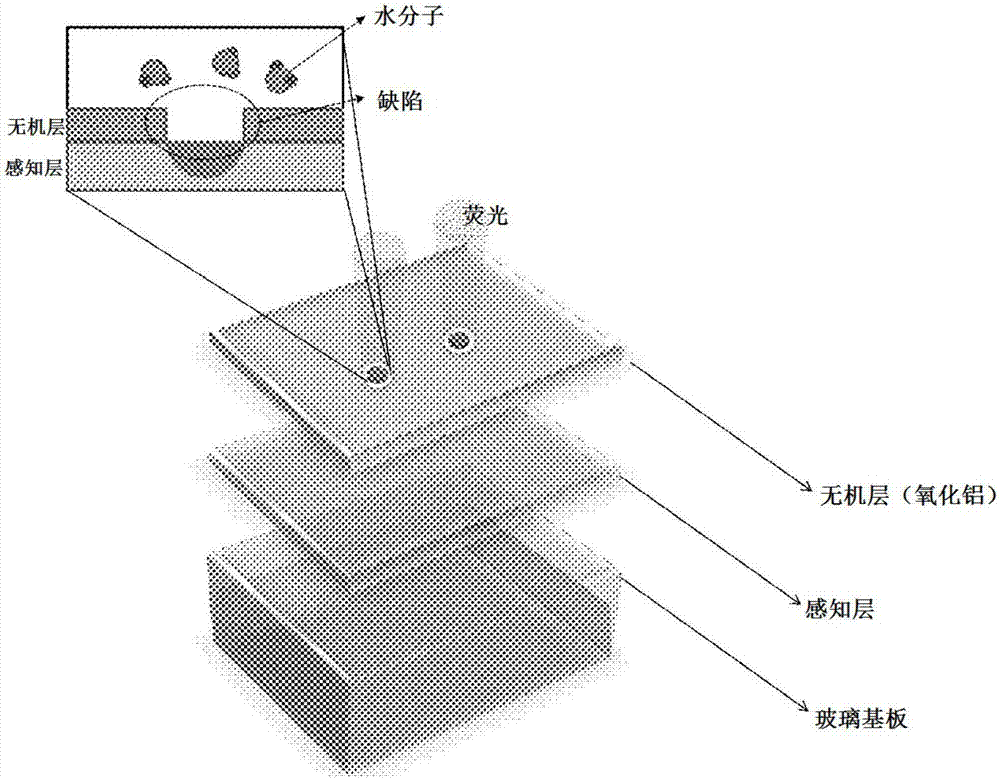

A detection sensor and defect detection technology, which is applied in the direction of optical testing defect/defect, instrument, analysis material, etc., can solve the problem of difficult application of substrate and barrier layer moisture penetration, difficult measurement of moisture penetration, and inability to obtain absolute moisture penetration rate and other issues, to achieve the effect of excellent sensitivity, fast response, and easy monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] (1) Manufacture of compounds that can easily detect moisture and film defects

[0054] The synthesis process of the compound using Chemical Formula 1 is as follows. Calcein (Calcein, 3-3'-Bis[N,N-di(carboxymethy)-aminomethy]fluorescein) and polyethylene oxide (polyethylene oxide, PEO) as a hydrophilic polymer were dissolved in dimethyl formaldehyde Dimethyl formamide (DMF), stirred at 80° C., 500 RPM for 1 hour.

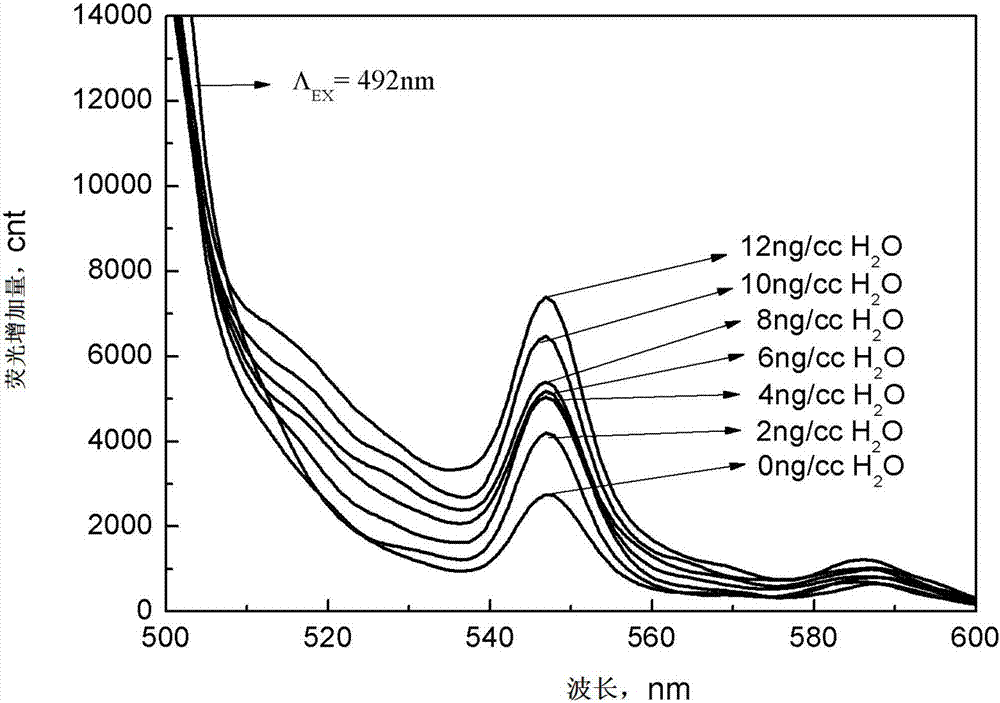

[0055] (2) Moisture Sensitivity Evaluation

[0056] In order to confirm the detection property of moisture, the fluorescence intensity based on the amount of moisture was measured using a fluorescence measuring device (PL Spectrometer, product of Shinko Co., Ltd., model: S-3100). The amount of 1 x 10-2 [M] of the compound of Chemical Formula 1 and PEO was adjusted to an amount of 0.05 wt% of DMF and added. The amount of moisture was increased by 20 ppm of moisture and an increase in fluorescence was observed. The results of the evaluation of moisture sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com