Hyaluronic acid-modified silicon-encapsulated drug-loading phospholipid liquid fluorocarbon nanosphere ultrasonic contrast agent and preparation method thereof

A technology of hyaluronic acid modification and ultrasound contrast agent, which is applied in the field of medical medicine, can solve the problems of complex process and poor stability, and achieve the effect of simple synthesis process, less time-consuming, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

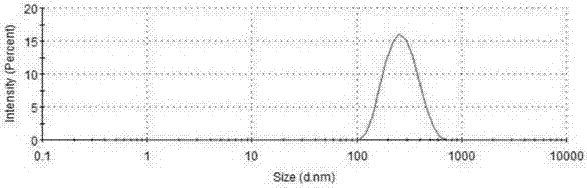

[0027] 1. Preparation of Phospholipid Liquid Fluorocarbon Nanospheres

[0028] 30 mg soybean lecithin (SPC) and 3 mg drug were dissolved in 2 mL dichloromethane. The dichloromethane was quickly removed by evaporation under reduced pressure, forming a lipid film. After adding 8 mL of phosphate buffer (pH 7.4), the lipid film was hydrated in an ultrasonic water bath for 5 minutes to obtain a crude milk. The rough milk was sonicated for 10 min with an ultrasonic cell breaker, and cooled in a refrigerator at 4° C. to obtain liposomes. Add 0.06 mL of PFP to the liposome suspension, and then use an ultrasonic cell disruptor to sonicate for 5 minutes under ice bath conditions to obtain drug-loaded phospholipid liquid fluorocarbon nanospheres.

[0029] 2. Preparation of aminated silicon-coated drug-loaded phospholipid liquid fluorocarbon nanospheres

[0030] Dilute 8 mL of phospholipid liquid fluorocarbon nanosphere suspension to 24 mL, adjust the pH to 8.5 with dilute ammonia wate...

Embodiment 2

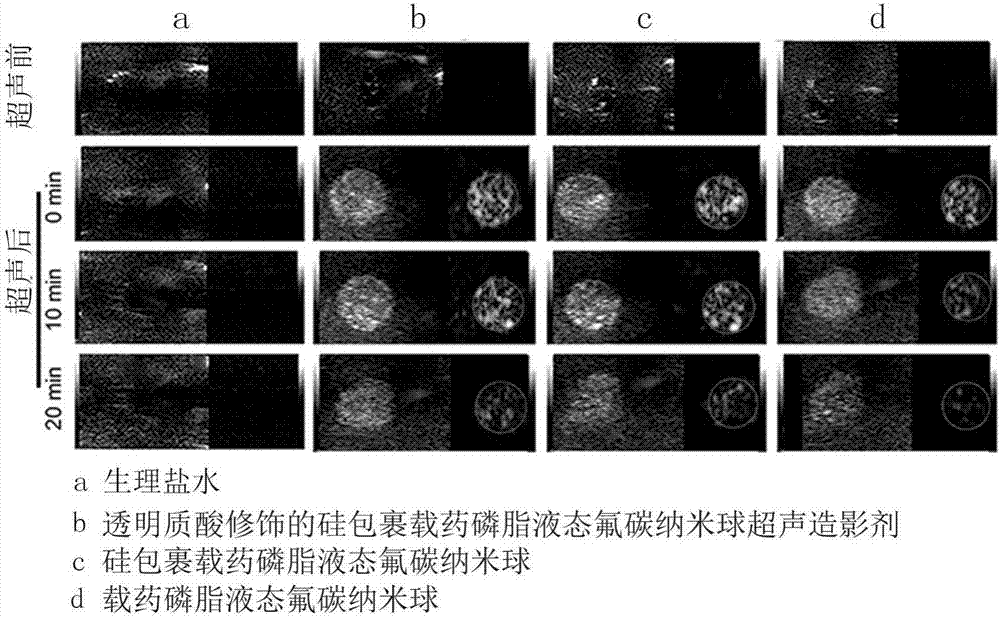

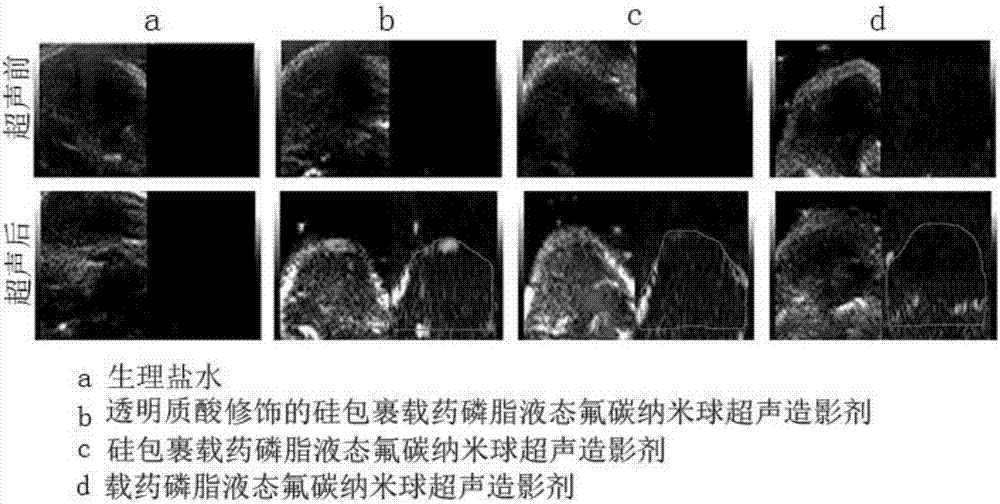

[0035] 1. In vitro heating-induced phase transition microscope observation of hyaluronic acid-modified silicon-coated phospholipid liquid fluorocarbon nanospheres ultrasound contrast agent

[0036] The prepared hyaluronic acid-modified silicon-coated drug-loaded phospholipid liquid fluorocarbon nanosphere ultrasound contrast agent suspension was added to a centrifuge tube, and then the centrifuge tube was put into a water bath, and the temperature was monitored with a thermometer. , 35, 45, 55, 65, 70°C) for 5 minutes, and then observe the morphology under an optical microscope. see results Figure 4 , the results show that when the temperature is lower than 55 °C, almost no bubbles are generated. When the temperature rises to 65°C, a small amount of bubbles can be observed, and when the temperature rises to 70°C, a large number of bubbles can be observed. The particle size analysis results show that when the temperature is heated from 25 to 55°C, the particle size increases...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com