Super-hydrophilic and under-water super-oleophobic ceramic film and preparation method thereof

An underwater super-oleophobic and ceramic membrane technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the unfavorable super-hydrophilic interface construction of nanotube structure, poor stability of super-hydrophilicity, and affect the use Longevity and other issues, to achieve the effect of abundant raw materials, easy mass production, and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

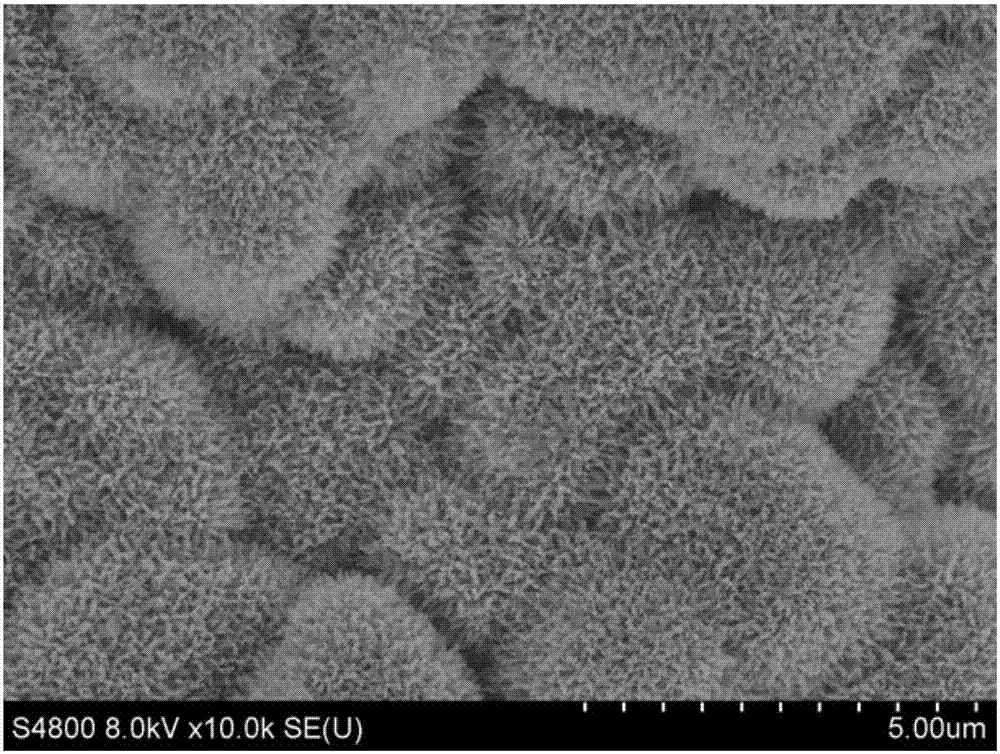

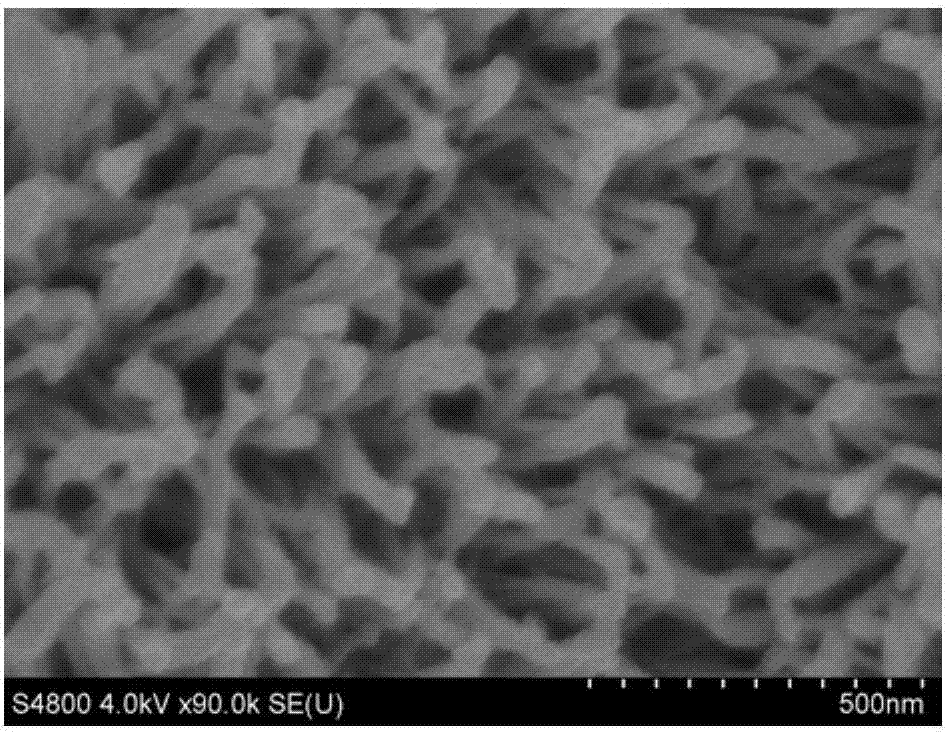

[0034] In this embodiment, the ceramic membrane is based on a porous alumina ceramic sheet, and nano-scale columnar titanium dioxide is arranged on the surface of the substrate to form a titanium dioxide nano-array on the surface of the substrate.

[0035] The preparation method of the ceramic membrane is as follows:

[0036] (1) Step 1: Soak the porous alumina ceramic sheet in a solvent for ultrasonic cleaning to remove stains and grease on the surface of the ceramic sheet, and then dry;

[0037] (2) Step 2: Fix the cleaned ceramic sheet on the magnetron sputtering equipment, use metal titanium as the target material, control the sputtering time for 2 hours, and obtain the ceramic sheet coated with titanium on the surface;

[0038] (3) Step 3: configure the oxidation solution, specifically: stir 3ml of 63% concentrated nitric acid, 70ml of 30% hydrogen peroxide, and 80mg of melamine at a temperature of 80°C until the melamine is completely dissolved;

[0039] (4) Step 4: Put...

Embodiment 2

[0047] In this embodiment, the structure of the ceramic membrane is similar to that of Embodiment 1. The porous alumina ceramic sheet is used as the substrate, and nano-scale columnar titanium dioxide is arranged on the surface of the substrate, forming a titanium dioxide nano-array on the surface of the substrate.

[0048] The preparation method of the ceramic membrane is basically the same as the preparation method in Example 1, except that in the process of configuring the oxidation solution in step 3, the addition amount of 63% concentrated nitric acid is 1 ml.

[0049] The SEM images of the ceramic membranes prepared above are similar to figure 1 As shown, nanoscale titanium dioxide is arranged on the surface of the substrate to form a titanium dioxide nano-array.

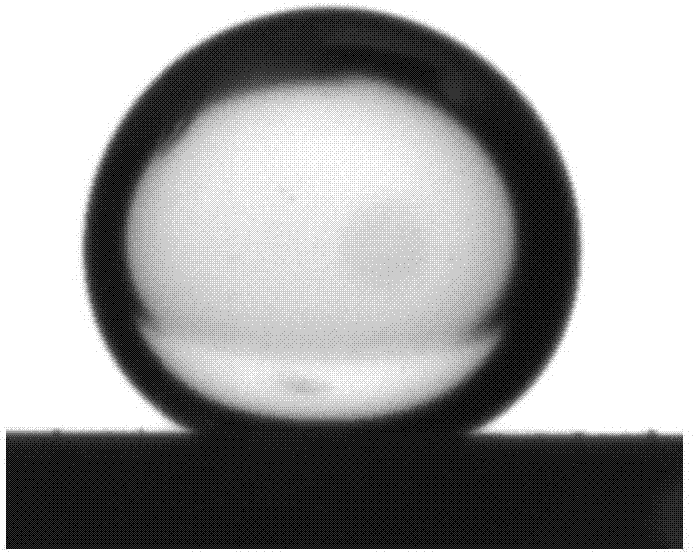

[0050]The ceramic membrane prepared above was tested for water contact angle in air, underwater chloroform contact angle test, and oil-water separation efficiency test. The test method is the same as the meth...

Embodiment 3

[0053] In this embodiment, the structure of the ceramic membrane is similar to that of Embodiment 1. The porous alumina ceramic sheet is used as the substrate, and nano-scale columnar titanium dioxide is arranged on the surface of the substrate, forming a titanium dioxide nano-array on the surface of the substrate.

[0054] The preparation method of the ceramic membrane is basically the same as the preparation method in Example 1, except that in the process of configuring the oxidation solution in step 3, the addition amount of 63% concentrated nitric acid is 5 ml.

[0055] The SEM image of the above-mentioned ceramic membrane is as follows: Figure 4 As shown, nanoscale titanium dioxide is arranged on the surface of the substrate to form a titanium dioxide nano-array.

[0056] The ceramic membrane prepared above was tested for water contact angle in air, underwater chloroform contact angle test, and oil-water separation efficiency test. The test method is the same as the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil-water separation rate | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com