Method for preparing 4-methylcatechol by using methanol and magnesium

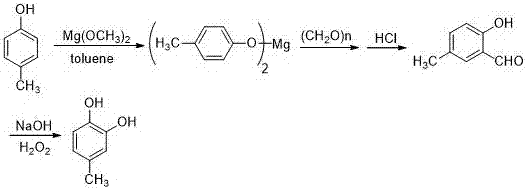

A technology of methyl catechol and magnesium methylate, applied in the field of 4-methyl catechol, can solve the problems of large amount of solvent, large amount of waste water, increased production cost and waste water, etc., and achieves mild reaction conditions and simple process route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0005] Magnesium powder (14.4 g, 0.6 mol) was put into a four-necked reaction bottle filled with 200 ml of methanol, and the electric stirring was turned on, a large number of bubbles were generated in the bottle, and the temperature rose to 61 °C. After 2h, the solution turned into a milky white suspension. P-cresol (108 g, 1.0 mol) was added to the reaction flask, methanol was distilled off after 50 min, and 200 ml of toluene was added after the reaction liquid became thick. Raise the temperature, and when the internal temperature reaches 95°C, add paraformaldehyde (90 g, 3.0 mol) in batches, change the device to a distillation device, and evaporate low-boiling substances. After 30 minutes, almost no fractions are distilled, and remove the distillation device , continue to react for 2.5h, followed by TLC point plate, p-cresol reacted completely. Stop heating, and when the internal temperature drops to 65°C, adjust the pH to 1 with 18.5% hydrochloric acid. After standing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com