Friction material for clutch driven disc and preparation method of friction material

A technology for friction materials and clutches, applied in the field of friction materials for clutch driven discs and its preparation, can solve problems such as single fiber reinforcement, and achieve the effects of reduced wear rate and high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

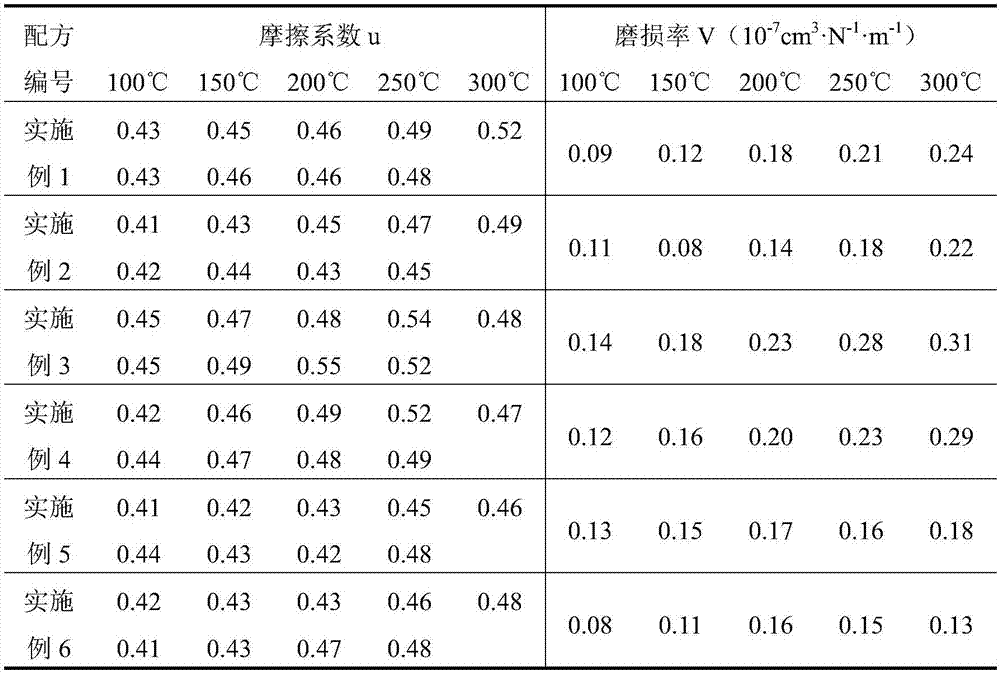

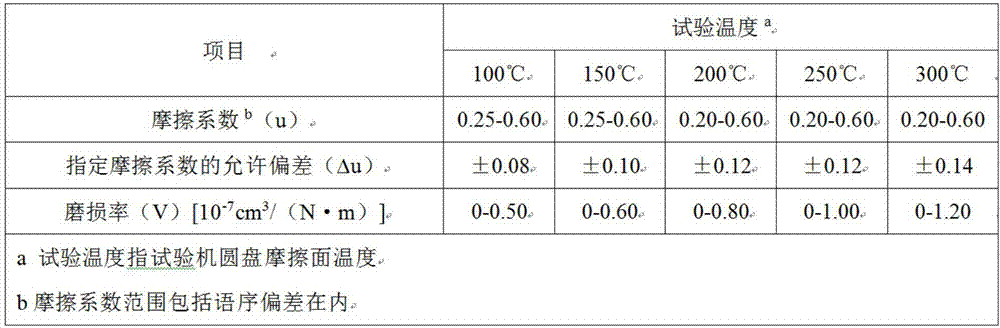

Examples

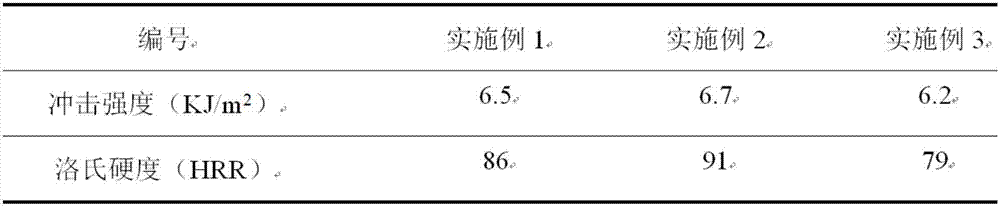

Embodiment 1

[0029] The friction material for the clutch driven disc is made of the following raw materials: cashew nut shell oil modified phenolic resin 14%, nitrile rubber powder 7%, basalt fiber 12%, steel fiber 7.4%, potassium titanate whisker 4.6%, barium sulfate 21% of powder, 12% of graphite, 6% of vermiculite, 5% of aluminum powder, 7% of barite, and 4% of brown corundum, all are mass percentages, and the total mass percentage of each component is 100%.

[0030] The preparation method of the friction material for the above-mentioned clutch driven disc, its steps are as follows:

[0031] (1) Batching: weigh each component in the formula by mass percentage;

[0032] (2) Mixing: First add basalt fiber, steel fiber and friction filler into the mixer and stir for 5-8 minutes. After mixing evenly, add cashew nut shell oil modified phenolic resin and potassium titanate whisker in turn, and then stir for 5- 8 minutes to mix evenly; the friction filler is barium sulfate powder, graphite, v...

Embodiment 2

[0036] The friction material for the clutch driven disc is made of the following raw materials: cashew nut shell oil modified phenolic resin 14%, nitrile rubber powder 7%, basalt fiber 12%, steel fiber 4.6%, potassium titanate whisker 7.4%, barium sulfate 21% of powder, 12% of graphite, 6% of vermiculite, 5% of aluminum powder, 7% of barite, and 4% of brown corundum, all are mass percentages, and the total mass percentage of each component is 100%.

[0037] Each raw material was weighed according to the above mass percentage, and prepared with the steps described in Example 1.

Embodiment 3

[0039] The friction material for the clutch driven disc is made of the following raw materials: cashew nut shell oil modified phenolic resin 14%, nitrile rubber powder 7%, basalt fiber 7.4%, steel fiber 12%, potassium titanate whisker 4.6%, barium sulfate 21% of powder, 12% of graphite, 6% of vermiculite, 5% of aluminum powder, 7% of barite, and 4% of brown corundum, all are mass percentages, and the total mass percentage of each component is 100%.

[0040] Each raw material was weighed according to the above mass percentage, and prepared with the steps described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com